A fireproof and heat-resistant PE composite bulletproof board and preparation method thereof

A ballistic plate, heat-resistant technology, applied in chemical instruments and methods, armor plate structure, layered products, etc., can solve the problem that the composite ballistic plate is easy to delaminate, the production process of the composite ballistic plate is complicated, and the protective function of the composite ballistic plate is reduced. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

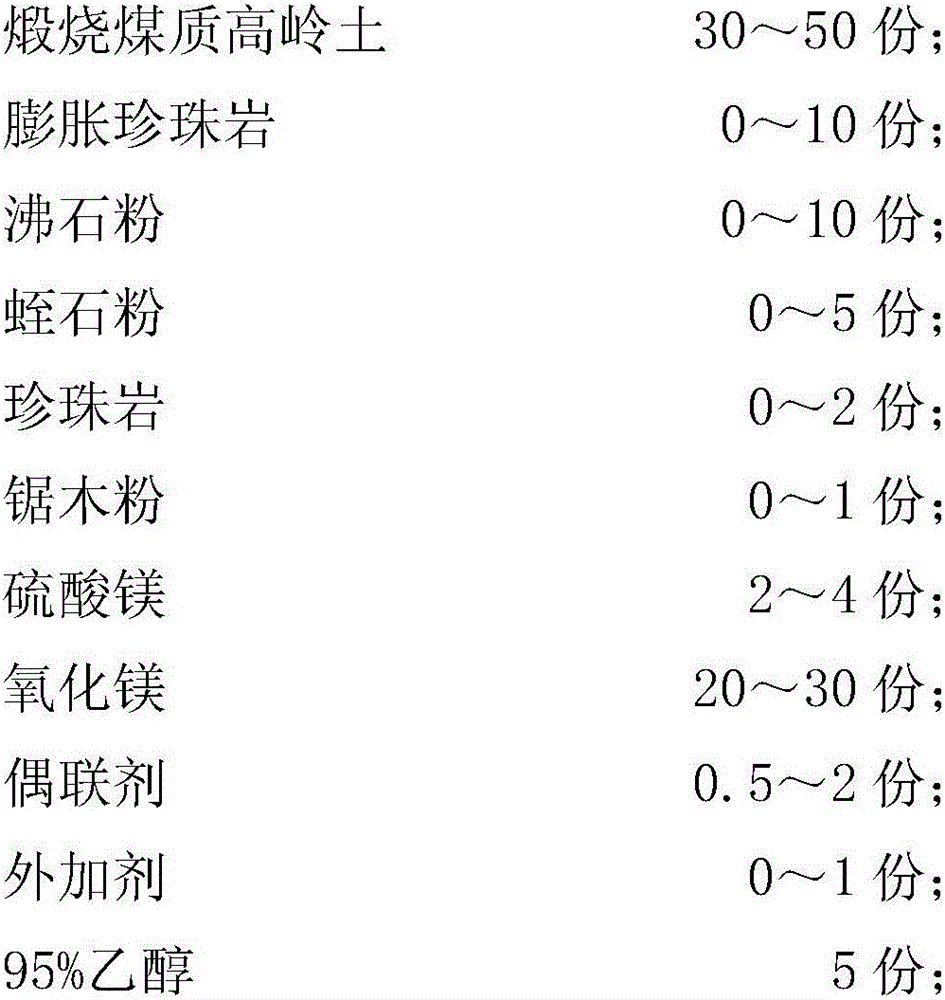

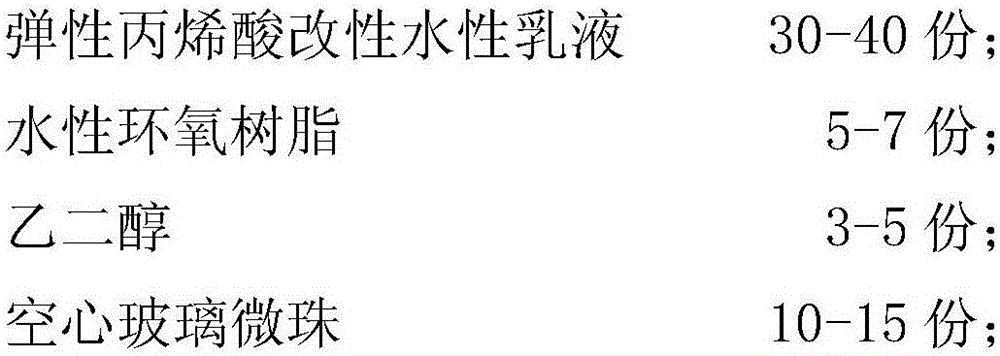

[0085] A method for preparing a fireproof and heat-resistant PE composite bulletproof board, specifically comprising the following steps:

[0086] (1) Pretreatment of calcined coal-based kaolin: Take 40kg of calcined coal-based kaolin of 4000 mesh and put it into a high-speed mixer, stir and heat to about 70°C, then dissolve 1.5kg of coupling agent with 6kg of ethanol to form a coupling agent solution , then slowly add the coupling agent solution to the calcined coal-based kaolin, stir while adding, continue to stir for 20 minutes, and then discharge and cool to 25°C to obtain the calcined coal-based kaolin modified powder; the coupling agent is silane

[0087] (2) Add 3kg of magnesium sulfate and 15kg of water into the reactor, heat to 40°C for dissolving, after the magnesium sulfate is completely dissolved, cool to normal temperature, add 20Kg of magnesium oxide into the reactor and stir evenly, add 1.5Kg of admixture, and then Add the calcined coal-based kaolin modified pow...

Embodiment 2

[0097] A method for preparing a fireproof and heat-resistant PE composite bulletproof board, specifically comprising the following steps:

[0098] (1) Pretreatment of calcined coal kaolin: take 70 kg of 1250 mesh calcined coal kaolin and put it into a high-speed stirrer, heat to 50 ° C for stirring, then dissolve 2 kg of coupling agent with 6 kg of 95% ethanol to form a coupling agent solution, and then Slowly add the coupling agent solution to the calcined coal-based kaolin, stir while adding, continue to stir for 20 minutes, then discharge and cool to 25°C to obtain a modified calcined coal-based kaolin powder; the coupling agent is lithium ester.

[0099] (2) Take 2kg of magnesium sulfate and 20kg of water and put them into the reactor, heat to 50°C to dissolve, after the magnesium sulfate is completely dissolved, cool to 20°C, add 30Kg of magnesium oxide into the reactor and stir evenly, and then follow the step (1) The prepared calcined coal-based kaolin modified powder a...

Embodiment 3

[0108] A method for preparing a fireproof and heat-resistant PE composite bulletproof board, specifically comprising the following steps:

[0109] (1) Pretreatment of calcined coal-based kaolin: Take 20kg of 3000 mesh calcined coal-based kaolin and put it into a high-speed mixer, stir and heat to about 70°C, then dissolve 0.75kg of coupling agent with 3kg of ethanol to form a coupling agent solution , and then slowly add the coupling agent solution to the calcined coal kaolin, stir while adding, continue to stir for 20 minutes, then discharge and cool to 25°C to obtain the calcined coal kaolin modified powder; the coupling agent is silane.

[0110] (2) Add 3kg of magnesium sulfate and 15kg of water into the reactor, heat to 40°C for dissolving, after the magnesium sulfate is completely dissolved, cool to normal temperature, add 20Kg of magnesium oxide into the reactor and stir evenly, add 1.5Kg of admixture, and then Add the calcined coal-based kaolin modified powder prepared ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com