Intercooling type two-stage absorption refrigeration system

An absorption refrigeration and cooling technology, applied in refrigerators, refrigeration and liquefaction, energy-saving heating/cooling, etc., can solve the problems of low efficiency and lack of control means, and achieve the expansion of application range, flexible adjustment and wide applicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

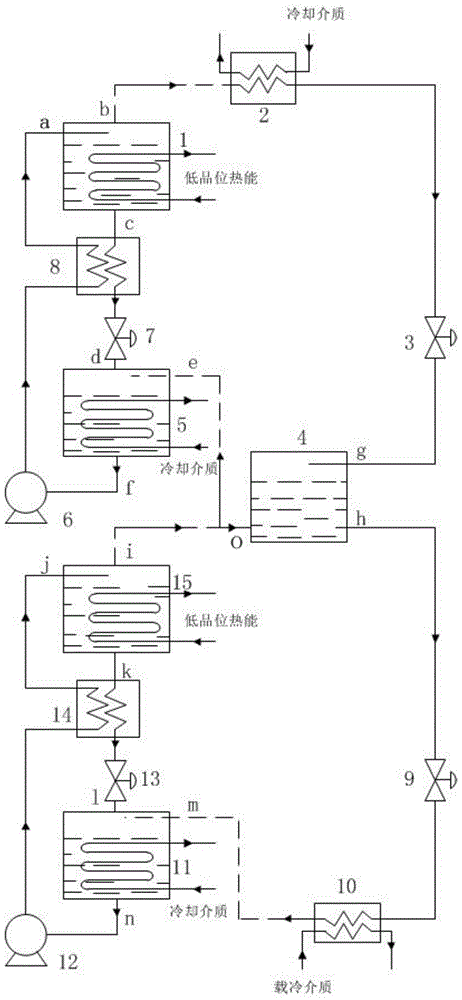

Embodiment 1

[0036] as attached figure 1 As shown, an intermediate cooling two-stage absorption refrigeration system, in which lithium bromide-water solution is used as the working fluid of the system circulation, lithium bromide is used as the absorbent, and water is used as the refrigerant. The entire system, including the high pressure absorption subsystem and the low pressure absorption subsystem, where:

[0037] The gas outlet a of the high-pressure generator 1 of the high-pressure absorption subsystem is connected to the inlet of the condenser 2, the outlet of the condenser 2 is connected to the inlet of the first throttling device 3, and the outlet of the first throttling device 3 is connected to the intercooler 4 The liquid inlet g of the high-pressure absorber 5 is connected with the inlet of the first circulating pump 6, and the outlet of the first circulating pump 6 is connected with the first channel inlet of the first solution heat exchanger 8, and the first solution is exchan...

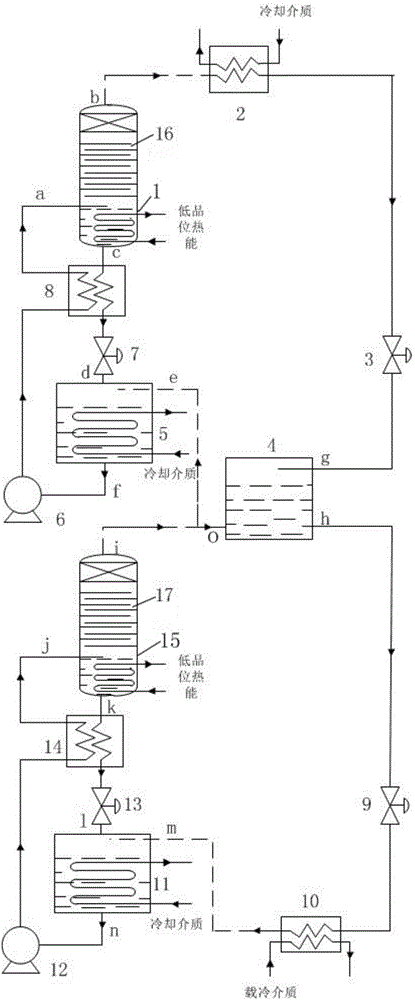

Embodiment 2

[0051] Such as figure 2 As shown, an intermediate cooling two-stage absorption refrigeration system, compared with Embodiment 1, is provided with a first rectification device 16 and a second rectification device 17 in the high-pressure generator 1 and the low-pressure generator 15 respectively.

[0052] The working fluid pair used in the refrigeration system in this embodiment is ammonia solution. Compared with Embodiment 1, the refrigeration system of this embodiment has added two rectification devices to make the refrigerant vapor generated by the generator purer and enhance the refrigeration capacity. The separation of solvents and absorbents, the working process of the system is as follows:

[0053] The ammonia solution at the bottom of the high-pressure generator 1 is driven by an external low-grade heat source to generate concentrated ammonia vapor with water and concentrated ammonia solution. The concentrated ammonia vapor is rectified in the first rectification colum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com