lng filling method for small ships

A marine, small-scale technology, applied in the direction of container filling method, container discharge method, equipment loaded into pressure vessels, etc., can solve the problems of pollution, high proportion of total amount, waste of resources and the environment, and achieve simple process, efficient recycling, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with specific embodiment the present invention is described in further detail:

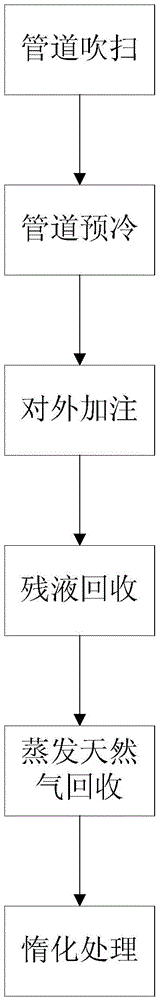

[0025] see Figure 1 to Figure 3 , the marine LNG fueling method of the present invention, comprises the steps:

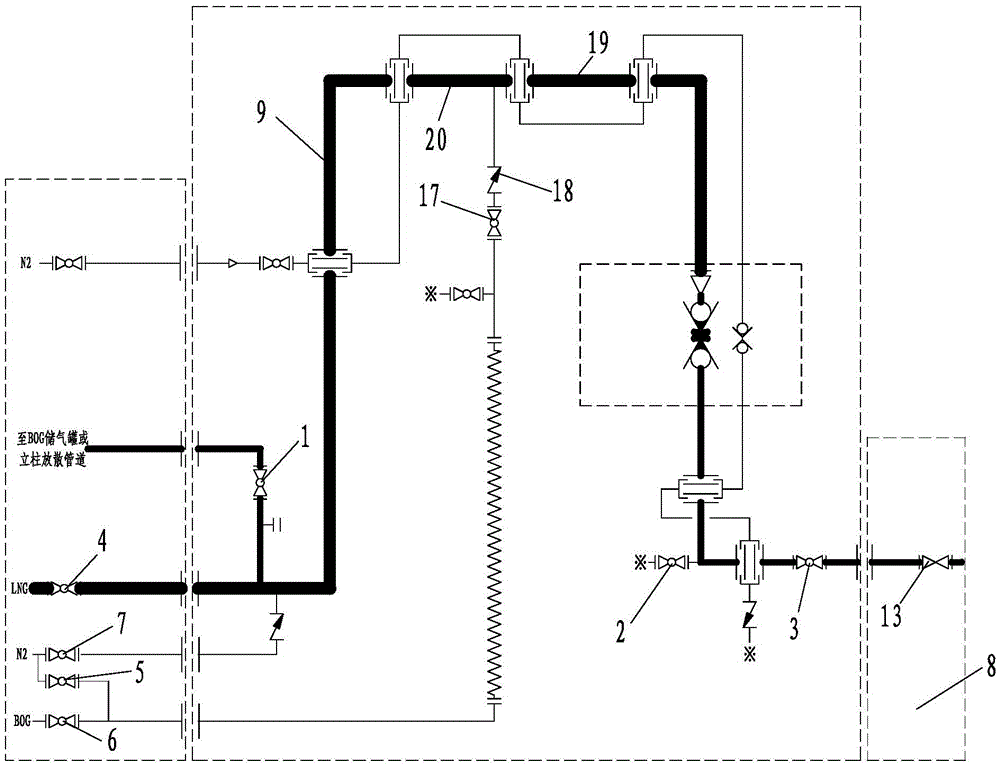

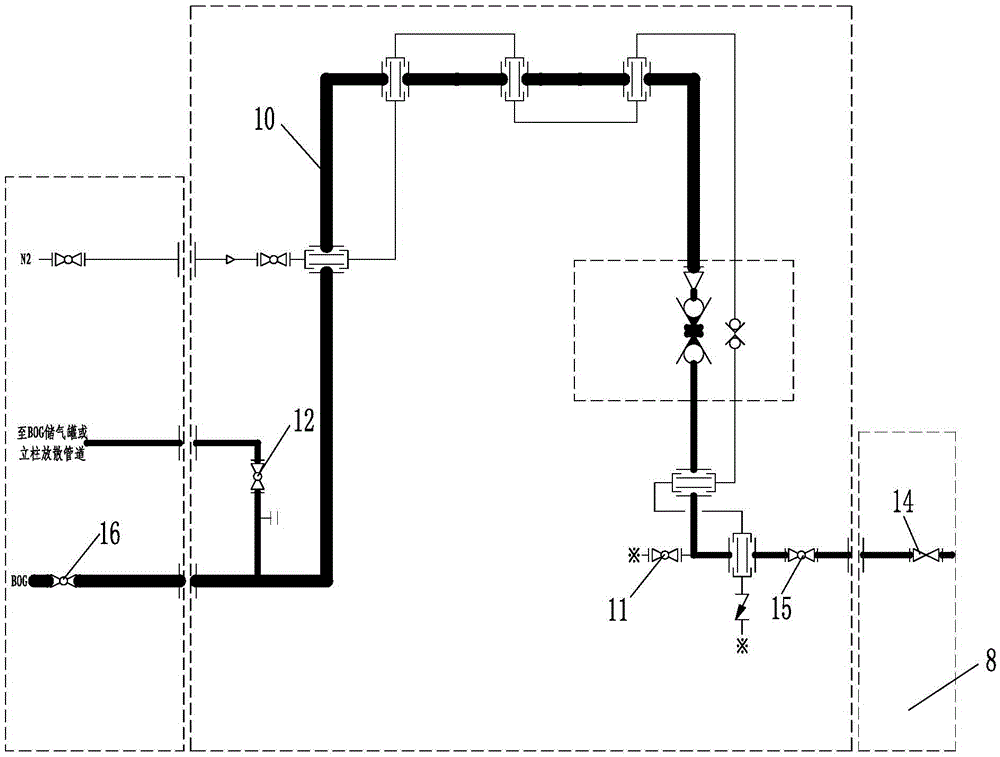

[0026] Step 1. Pipeline purging: before the small marine LNG filling arm is officially put into use, or it has not been used for a long time, before it is put into use again, use compressed air or nitrogen as the medium to clean the residual impurities in the pipeline of the small marine LNG filling arm. Clean up the waste and excess to ensure that the pipeline of the LNG filling arm for small ships is clean. The specific operations are: confirm the first liquid phase filling arm ball valve 1, the delivery filling arm vent valve 2, the second liquid phase filling arm ball valve 3, the LNG liquid inlet valve 4, the branch pipe inert gas purge valve 5 and BOG purge Valve 6 is closed, open the main inert gas purge valve 7 to introduce inert gas, the inert gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com