Comprehensive energy utilizing device for diesel generator

A technology of diesel generators and turbogenerators, which is applied in the direction of engine components, combustion engines, machines/engines, etc., can solve the problems of exacerbating the global warming effect and energy waste, so as to improve the comprehensive utilization efficiency, improve the recycling rate, Large effect of heat storage energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

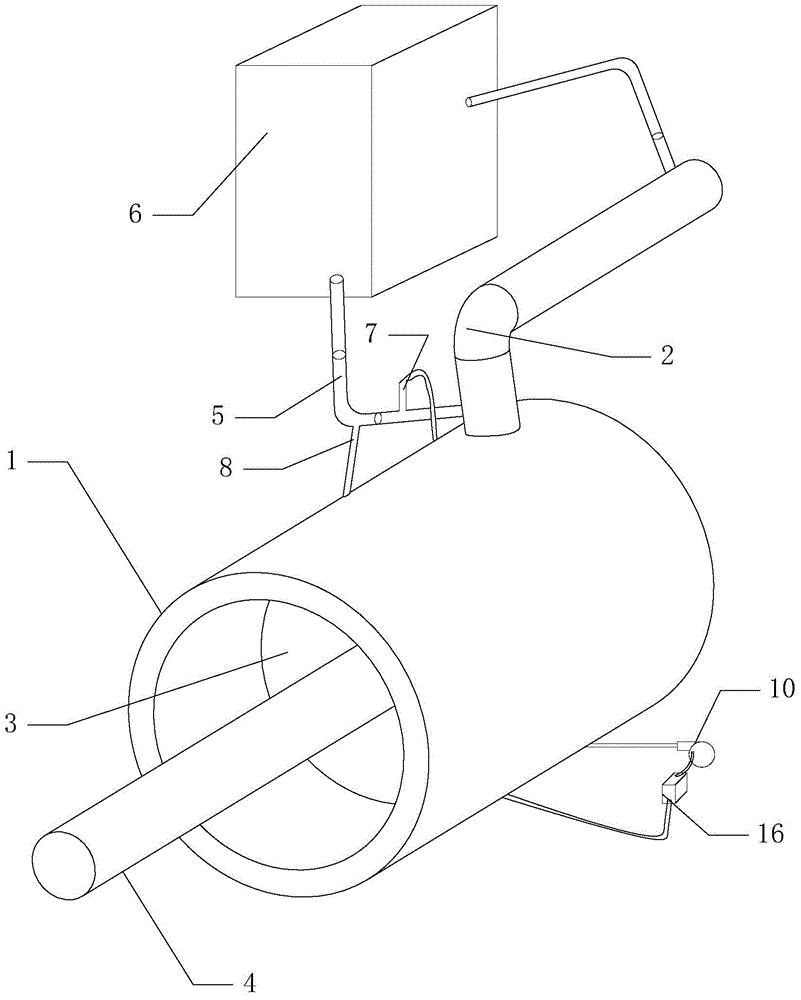

[0026] An energy comprehensive utilization device for a diesel generator, comprising a cylinder body 1, an exhaust pipe 2 and a superheated steam generator 6, the exhaust pipe 2 is connected to the cylinder body 1, and a spiral heat exchange tube 5 is arranged inside the exhaust pipe 2, The outside of the spiral heat exchange tube 5 passes through the hot steam generator 6 ; the spiral heat exchange tube 5 is provided with a liquid tin injection port 7 and a liquid tin recovery port 8 .

[0027] In this embodiment, the cylinder body 1 has a double-layer structure, and the middle part of the double-layer structure is a tin storage space 9; the tin storage space 9 is connected to the liquid tin injection port 7 and the liquid tin recovery port 8 through pipelines. At the initial stage of diesel generator operation, the solid tin stored in the tin storage space 9 is first melted, and enters the spiral heat exchange tube 5 through the liquid tin injection port 7, so that the spiral...

Embodiment 2

[0035] An energy comprehensive utilization device for a diesel generator, comprising a cylinder body 1, an exhaust pipe 2 and a superheated steam generator 6, the exhaust pipe 2 is connected to the cylinder body 1, and a spiral heat exchange tube 5 is arranged inside the exhaust pipe 2, The outside of the spiral heat exchange tube 5 passes through the hot steam generator 6; the spiral heat exchange tube 5 is provided with a liquid tin injection port 7 and a liquid tin recovery port 8.

[0036] In the present embodiment, also comprise the second tin circulation pump 17 and tin tank 11; , The inlet end of the tin tank 11 is connected to the liquid tin recovery port 8 .

[0037] An electric heating wire is arranged in the tin bath 11 .

[0038] The electric heating wire is coiled in the tin bath 11 in a helical shape.

[0039] The superheated steam produced by the superheated steam generator 6 can be directly used for cooking and heating articles, which greatly improves the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com