Integrated exhaust manifold type three-cylinder machine cooling water jacket

A technology for cooling water jackets and exhaust manifolds, applied to cylinders, cylinder heads, mechanical equipment, etc., can solve problems such as uneven flow, cylinder head failure, and slow warm-up speed, and achieve good fatigue resistance and excellent durability Corrosiveness, effect that increases warm-up speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

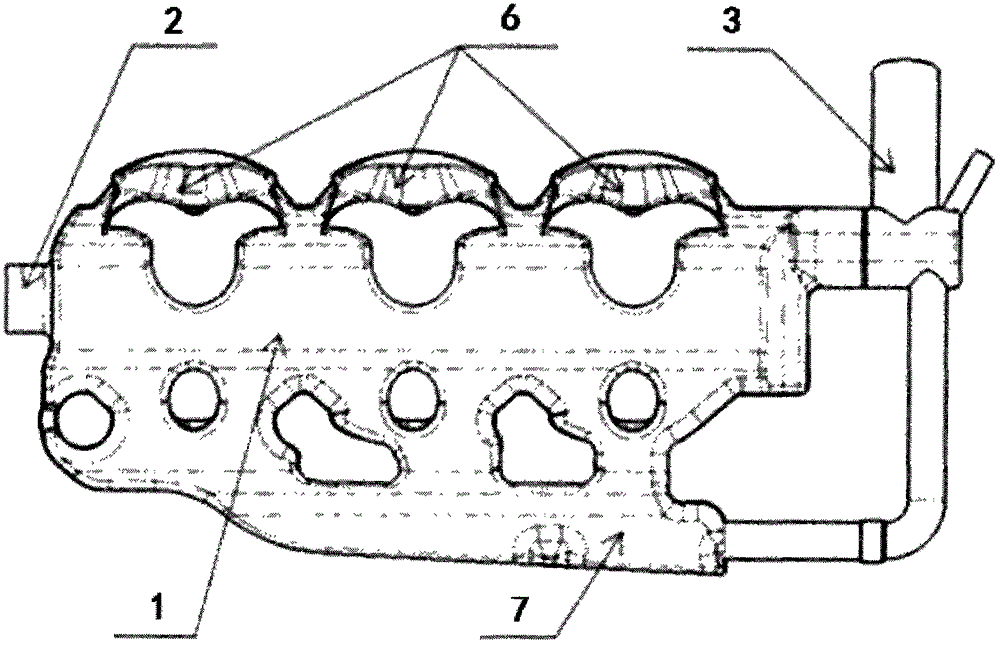

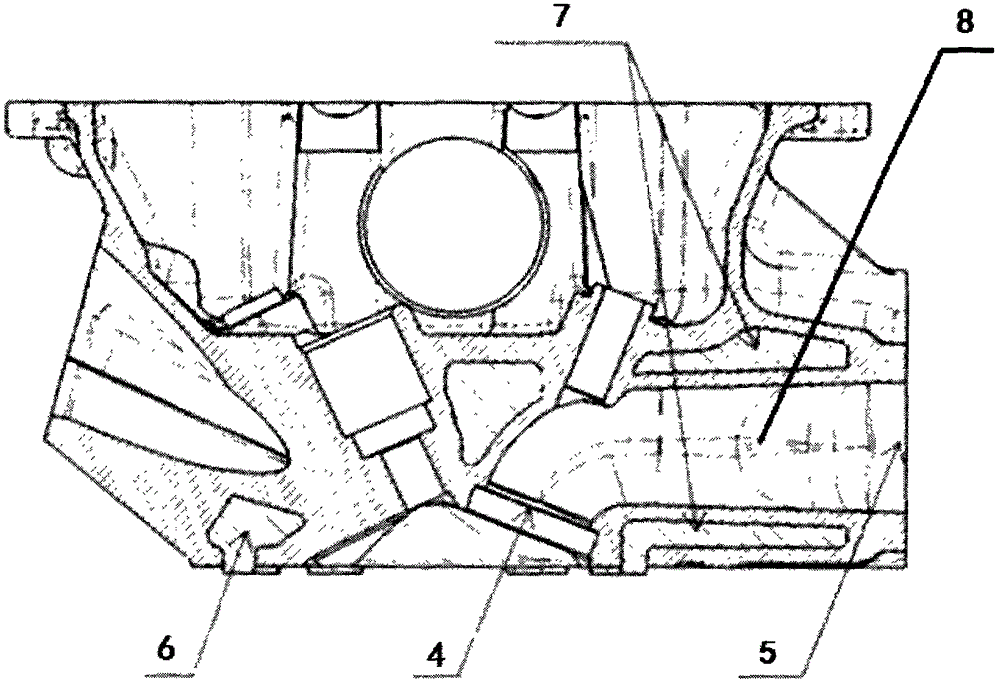

[0015] like Figure 1~2 As shown, the integrated exhaust manifold type three-cylinder engine cooling water jacket described in this embodiment includes a cylinder head with an intake side and an exhaust side, and the exhaust side of the cylinder head has an exhaust throat 4 and exhaust port 5, and an exhaust manifold 8 is also integrated between the exhaust throat 4 and the exhaust port 5; the front end of the cylinder head has a water inlet 2, and the rear end of the cylinder head has a A water outlet 3, a cooling water channel 1 is provided between the water inlet 2 and the water outlet 3; an exhaust side water jacket 7 connected to the cooling water channel is provided at the upper end and the lower end of the exhaust manifold 8, and The air intake side of the cylinder head is provided with an air intake side water jacket 6 connected to the cooling water channel.

[0016] In this embodiment, cooling water jackets are designed on the upper and lower end surfaces of the inte...

Embodiment 2

[0018] The cylinder head described in the present invention has complex internal structures such as water channels and exhaust manifolds, so the aluminum alloy used in the cylinder head needs to have good fluidity under molten conditions. In the present invention, the composition of the alloying elements of the aluminum alloy is: 4.5-5.0wt% Si, 1.0-1.2wt% Cu, 0.45-0.50wt% Mg, 0.55-0.60wt% Mn, 0.20 -0.30 wt% Fe, 0.12-0.15 wt% Zr, 0.03-0.05 wt% Te, 0.03-0.05 wt% Sr, and the balance Al. The aluminum alloy can be prepared by melting aluminum ingots (such as Al99.90, Al99.9, Al99.85) or aluminum-based master alloys as main raw materials, adding alloy elements in a melting furnace, and using an inert gas such as N 2 etc. for purging, degassing and cleaning. Obtaining a cylinder head of a desired shape by melting and casting aluminum alloy belongs to the prior art in this field. Simply put, the molten aluminum alloy is cast into a wax mold or a metal mold to solidify. The suitable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com