Coal underground gasification device and gasification method thereof

A technology for underground gasification and coal, which is applied in the fields of coal gasification, underground mining, and earth-moving drilling, etc., can solve the problems of reducing work efficiency, long time required for staged gasification, and affecting the effect of underground gasification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

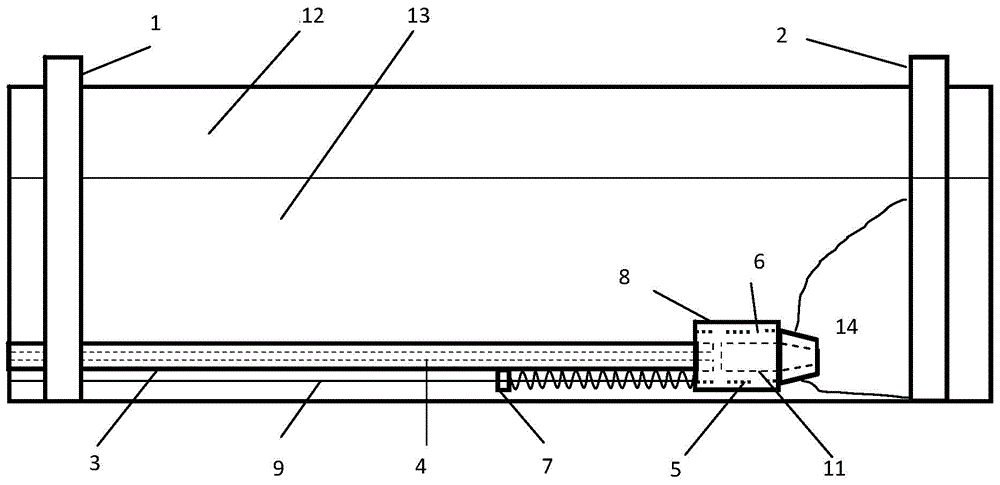

[0035] The underground coal gasification device and its gasification method according to the present invention will be introduced in detail below in conjunction with the accompanying drawings.

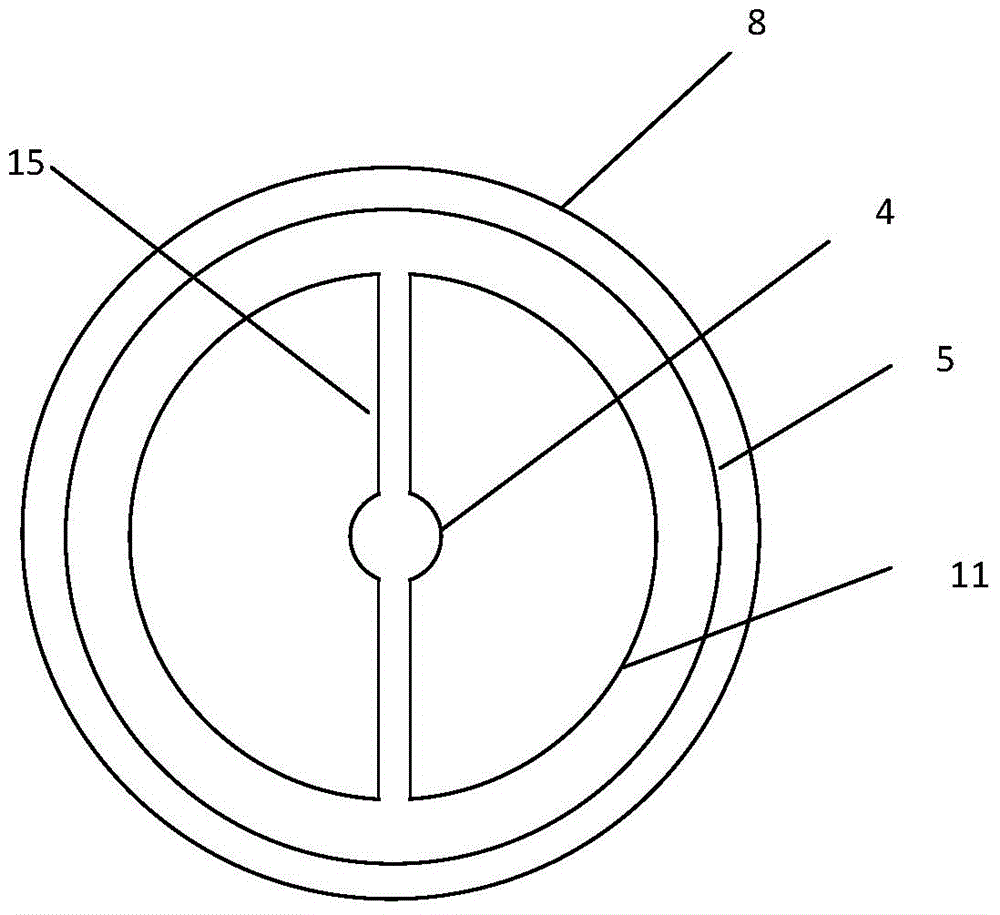

[0036] see figure 1 , an underground coal gasification device, comprising a gas injection pipe 3, a water inlet pipe 4 located in the gas injection pipe 3 and a nozzle 11 fixedly connected to the gas injection pipe 3, the nozzle 11 is provided with a water jacket 5 communicating with the water inlet pipe 4, and the water The shaft wall of the jacket 5 is provided with a water injection hole 6 for water supply outflow, and the water jacket 5 is equipped with a water injection control sleeve 8 for controlling the water discharge. It is fixed on the gas injection pipe 3, and the other end is against the jet control sleeve 8.

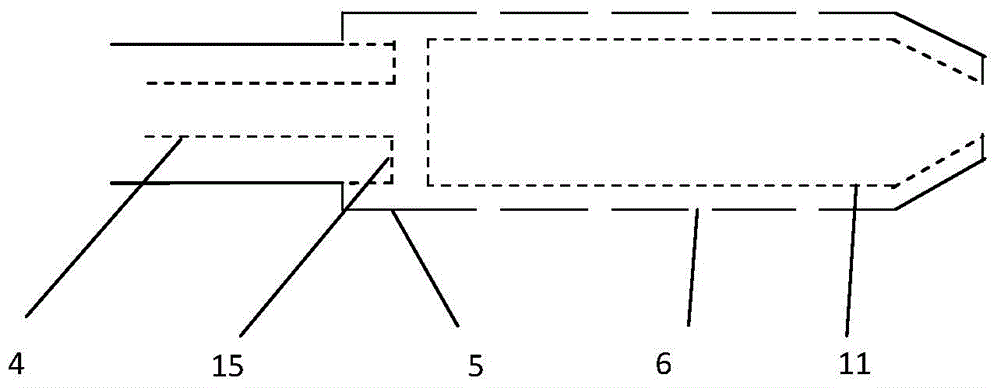

[0037] see figure 2 One end of the water jacket 5 is connected to the water inlet pipe 4, and the other end is closed and connected to the end of the nozzle 11 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com