A mechanical vibrator with a safety interlock device

A technology of safety interlock device and vibrator, which is applied in electrostatic separation, electrode cleaning, etc., can solve the problems of operator injury and potential safety hazards, and achieve the effect of structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

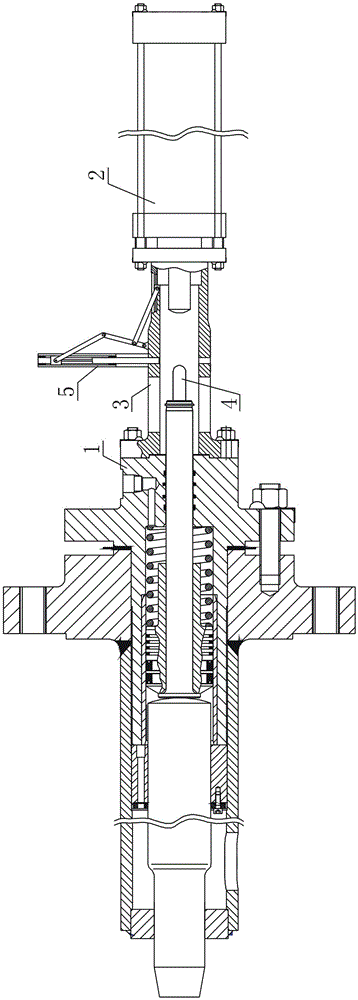

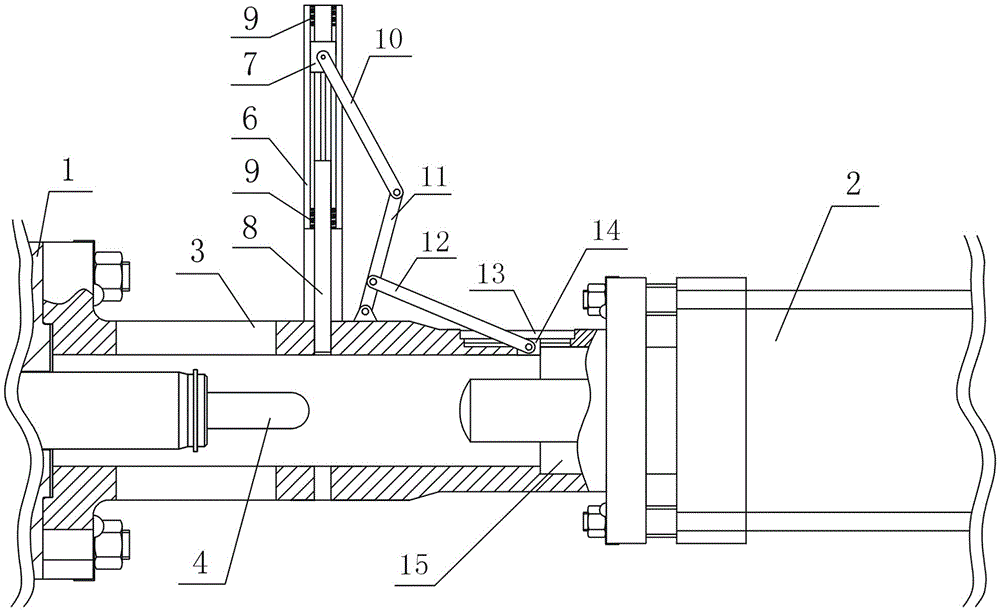

[0014] Such as figure 1 , 2 As shown, a mechanical rapper with a safety interlock device (mainly composed of rapping parts, seals, filter elements and supporting connectors, etc., and is equipped with a cylinder 1 to form a rapping device to remove dust accumulation, The purpose of maintaining heat transfer efficiency. The main components of the mechanical rapper are piston 1, convex flange, piston rod 4, piston bushing, piston guide tube, conduit, impact rod and guide tube, etc.), which mainly consists of piston 1 and cylinder 2, the piston 1 is provided with a piston rod 4, the piston 1 and the cylinder 2 are connected by a positioning bracket 3, the positioning bracket 3 is a cylindrical structure, and the two ends are respectively connected to the piston 1 and the cylinder 2 Fixedly connected by bolts, wherein the right end of the piston rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com