A digital dispensing test deployment system and method

A digital, regulating system technology, applied in the directions of measurement, earthwork drilling, and fluid extraction, to solve the low success rate and efficiency of test deployment and improve the level of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

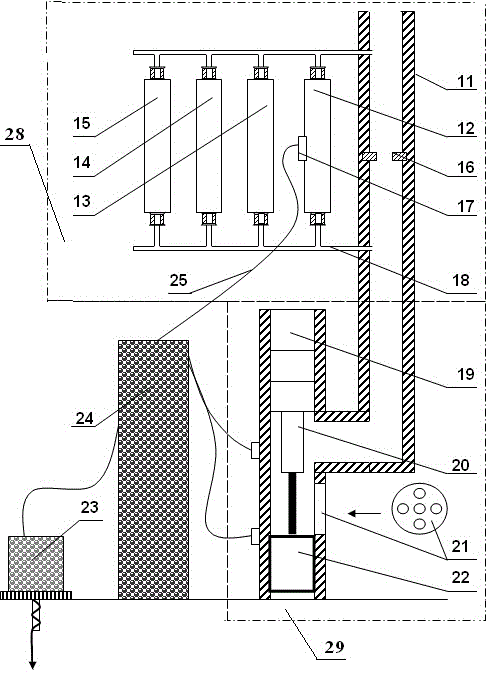

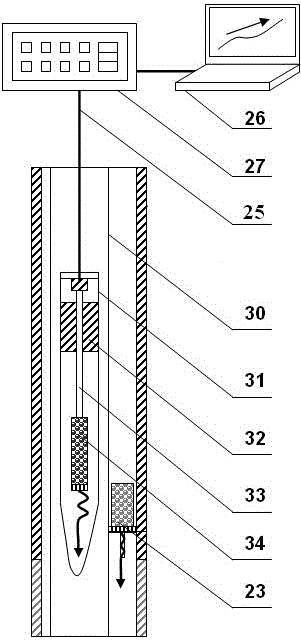

[0034] In order to overcome the problems existing in the existing test and deployment technology of layered water injection, and solve the problem of test and deployment of conventional technology in highly deviated wells, deep wells and produced water reinjection wells. This embodiment provides a digital dispensing test deployment system, including a digital water distributor 5, a downhole measurement and control instrument and a ground control and adjustment system, and the downhole measurement and control instrument and the ground control and adjustment system are connected by cables;

[0035] The digital water distributor 5 is equipped with a wireless module 23, a central module 24, a flow testing system 28 and a flow regulating system 29; the downhole measurement and control instrument transmits the flow command of the ground control and regulating system to the wireless module 23 through a wireless signal, and the wireless module 23 will receive The received signal is tra...

Embodiment 2

[0039] On the basis of Example 1, such as figure 1 As shown, the flow test system 28 includes an orifice plate 16 symmetrically arranged on the inner wall of the flowmeter flow passage 11, a pressure guide pipe 18 drawn through the flowmeter flow passage 11, and a series of pressure guide pipes 18 connected in sequence and connected in series. Differential pressure sensor 12, positive one-way valve 13, reverse one-way valve 14 and bellows 15. 14 communicates with the upper and lower ends of bellows 15.

[0040]An induction piece 17 is arranged on the outside of the differential pressure sensor 12, and the induction piece 17 is connected with the central module 24 through a cable. The orifice plate 16 is inlaid on the inner wall of the flowmeter flow passage 11 to generate pressure loss for the measurement of the differential pressure sensor. The pressure guiding pipe 18 is drawn from the inner wall of the flowmeter flow passage 11 on both sides of the orifice plate 16 through...

Embodiment 3

[0044] This embodiment provides a digital dispensing test deployment method, comprising the following steps:

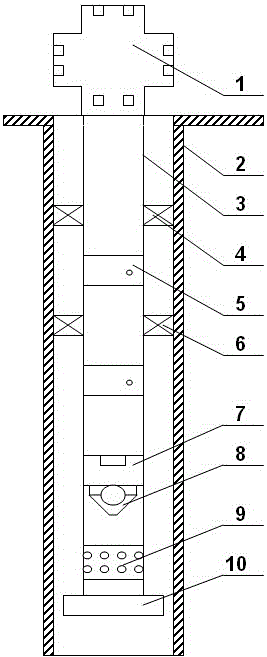

[0045] Step 1) Run the tool string into the oil well casing 2: from top to bottom, put the casing protection packer 4, digital water distributor 5, packer 6, preset working cylinder 7, check valve 8, screen The pipe 9 and the plug 10 are connected with the oil pipe 3 and then lowered into the casing 2, such as figure 2 As shown, the fluid injected into the water injection well by the water injection wellhead 1 reaches the digital water distributor 5 through the oil pipe 3, and enters the formation after automatic testing and deployment;

[0046] Step 2) Turn on the digital water distributor 5. Under the command of the central module 24, the motor 19 is turned on, and the power transmission rod 20 is driven to move, and the movable cylinder 22 moves downward to open the water nozzle 21 to the preset position to inject water into the oil and gas well ;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com