Movable loading frame

A material rack and movable rod technology, which is applied in the field of movable material racks, can solve the problems of high construction cost, affecting the construction period, time-consuming and labor-intensive inner wall of the material rack storage tank, etc., so as to save construction time, improve construction efficiency, and facilitate transfer Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the technical solution of the present invention is further described:

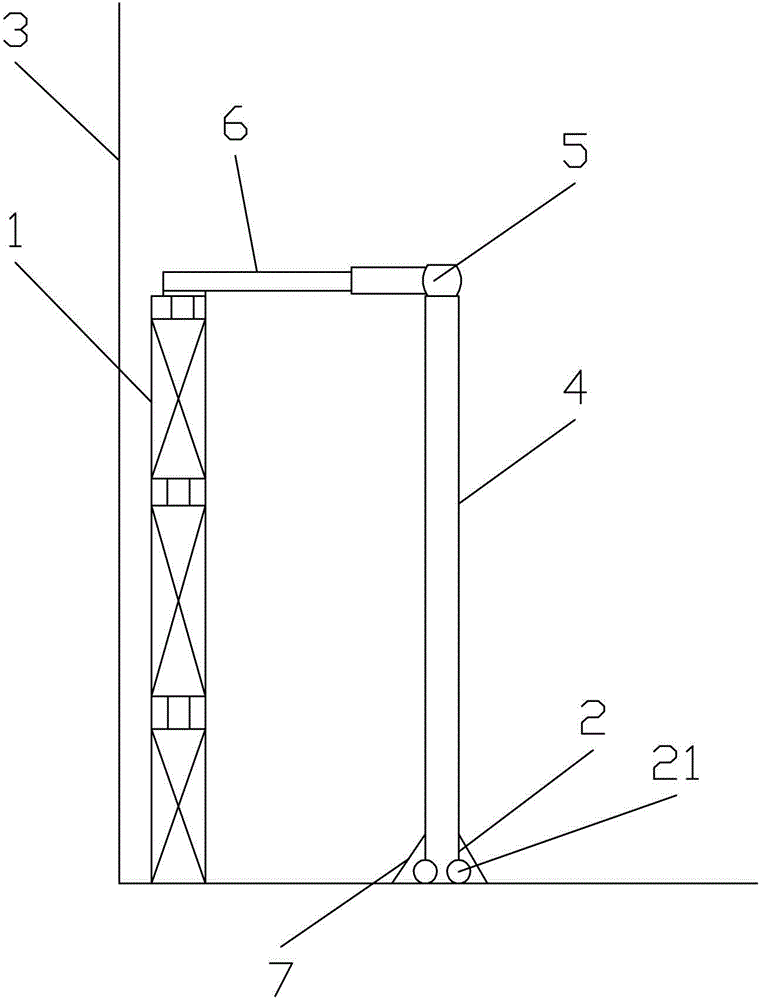

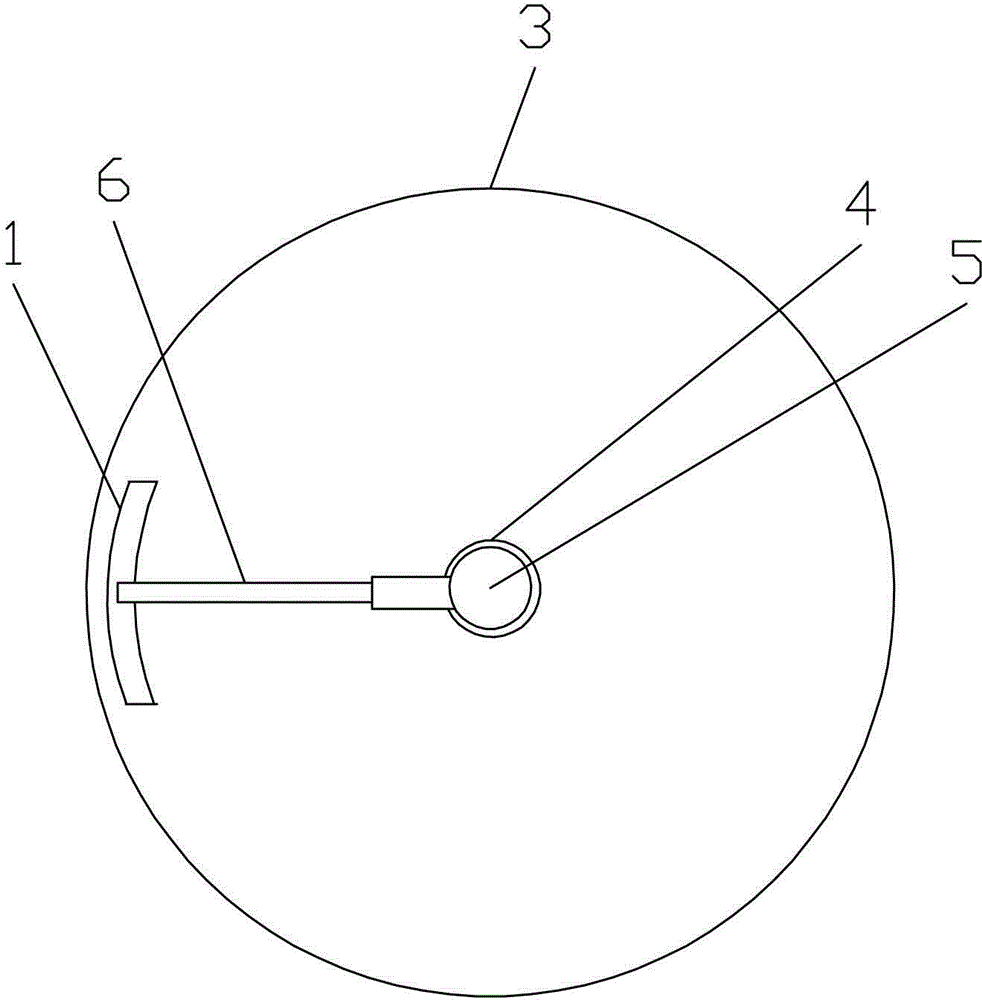

[0014] Such as figure 1 and figure 2 As shown, the present invention provides a movable feeding rack, comprising a feeding rack frame body 1, a movable device 2 is installed at the bottom of the feeding rack frame body 1, and a telescopic support rod 4 arranged in a storage tank 3 is also included , the rotary drive device 5 located at the top of the telescopic support rod 4, the movable rod 6, one end of the movable rod 6 is fixedly connected with the rotary drive device 5, and the other end is fixedly connected with the upper part of the feeding rack frame body 1, and the movable device 2 comprises a roller 21, and the periphery of the roller 21 is provided with a positioning plate 7, and the positioning plate 7 is two pieces. In addition, a protective cover is provided on the periphery of the feeding rack frame body 1, four mobile d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com