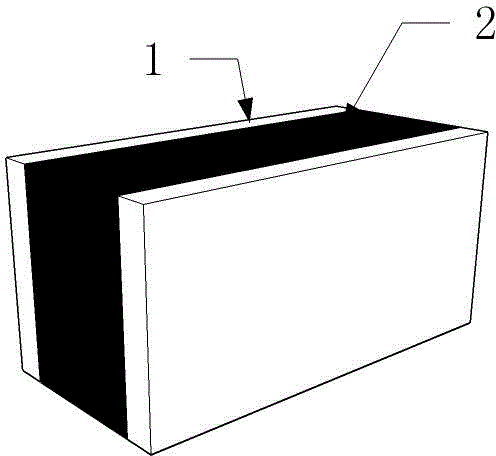

Rod-shaped connected composite self-insulating building block and production method thereof

A self-insulating block and rod-shaped technology, applied in building materials and other directions, can solve the problems of poor thermal insulation effect, many stress concentration parts, and increased construction procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] a. The foaming agent foam is obtained by configuring the foaming agent aqueous solution to foam the foaming agent and water according to the mass ratio of 1:30;

[0028] b. According to the mass parts of the ingredients, 35 parts of cement, 30 parts of fly ash, 8 parts of lightweight aggregate, and 27 parts of water are mixed and stirred evenly, and the foaming agent foam whose volume is 40 times the volume of the solid aggregate is mixed with the solid aggregate. Uniform;

[0029] c. Pour the mixed slurry into the mold and maintain it for a specified number of days;

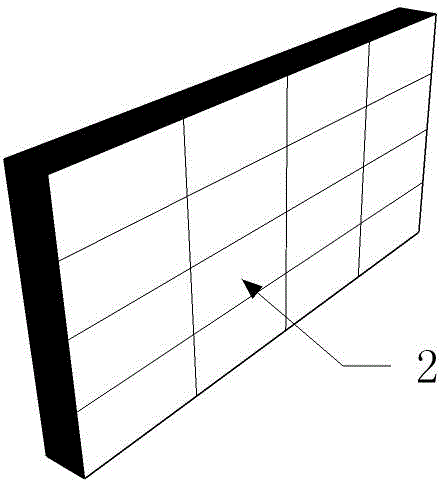

[0030] d. Cut the large foam concrete slab that has reached the specified strength into the middle foam concrete slab of the designed size, and open a through hole on the slab, such as image 3 , 4 ;

[0031] e. According to the mass parts of ingredients, 25 parts of cement, 25 parts of fly ash, 34.7 parts of fine aggregate, 0.3 parts of fiber filament, and 15 parts of water are mixed into concret...

Embodiment 2

[0037] a. The foaming agent foam is prepared by preparing the foaming agent aqueous solution and foaming the foaming agent and water according to the mass ratio of 1:40;

[0038] b. According to the mass parts of the ingredients, 38 parts of cement, 32 parts of fly ash, 6 parts of lightweight aggregate, and 24 parts of water are mixed and stirred evenly, and the foaming agent foam whose volume is 29 times the volume of the solid aggregate is mixed with the solid aggregate. Uniform;

[0039] c. Pour the mixed slurry into the mold and maintain it for a specified number of days;

[0040] d. Cut the large foam concrete slab that has reached the specified strength into the middle foam concrete slab of the designed size, and open a through hole on the slab, such as image 3 , 4 ;

[0041] e. According to the mass parts of the ingredients, 22 parts of cement, 28.6 parts of fly ash, 31 parts of fine aggregate, 0.4 part of fiber filament, and 18 parts of water are mixed into co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com