Construction equipment for retaining walls

A construction device and retaining wall technology, applied in the field of geotechnical engineering, can solve the problems of large amount of concrete application, slow manual construction speed, high cost, etc., and achieve the effect of saving concrete amount and fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

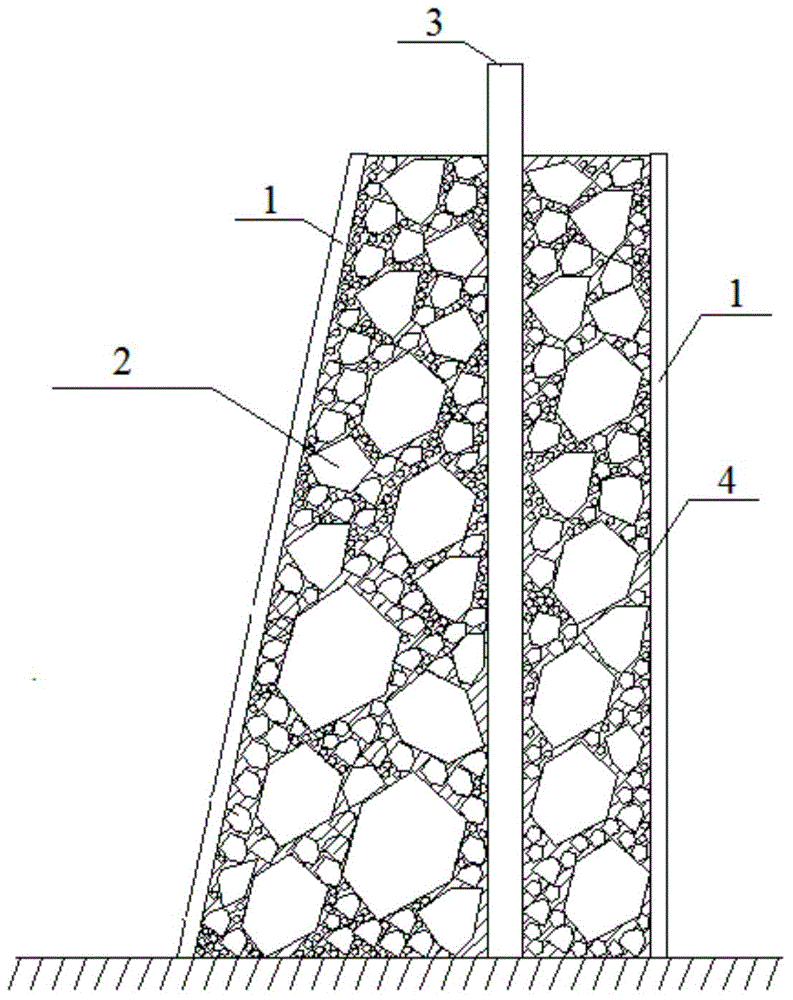

[0013] The present invention will be described in detail below with reference to the accompanying drawings and examples.

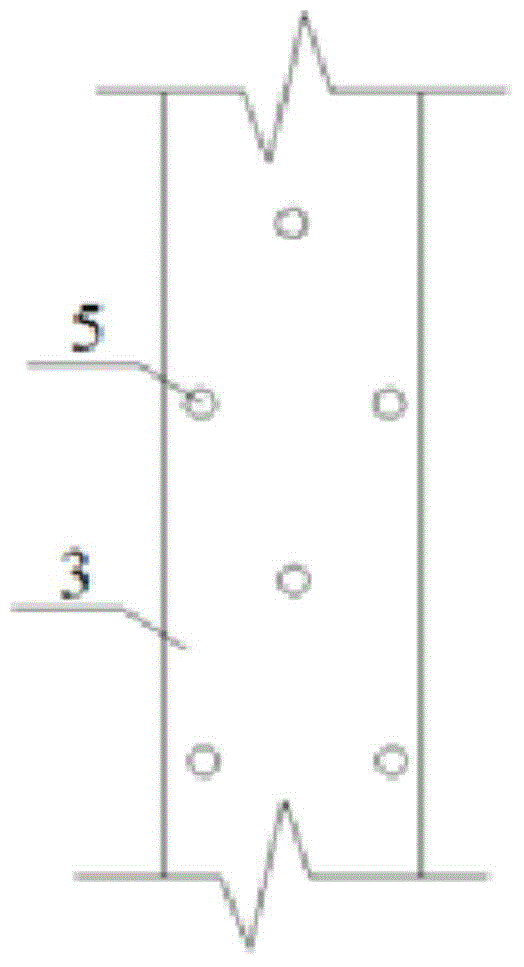

[0014] First support the retaining formwork 1 according to the designed retaining wall shape, height and width and fix the retaining formwork 1 on the plane, then fix a plurality of grouting pipes 3 between the two retaining formworks 1, the grouting pipes 3. The layout spacing should not be greater than 2 / 3 of the height of the retaining wall. Because the grouting pressure is not large, in order to save costs, the grouting pipe 3 can adopt a certain strength PVC pipe. When the thickness of the retaining wall is moderate, a plurality of grouting pipes 3 can be arranged at equal intervals along the centerlines of the two retaining formworks 1; A plurality of grouting pipes 3 are arranged in a plum blossom shape between the two retaining formworks 1, so as to ensure the uniformity of grouting. Then fill the stone material 2 into the retaining template 1 (t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com