Method for manufacturing wrapped twisted yarns with spandex wrapped by silk

A production method and twisting technology, applied in the direction of textiles, papermaking, yarn, etc., can solve the problems of restricting the wide application of silk elastic fabrics and unable to meet rich desires.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

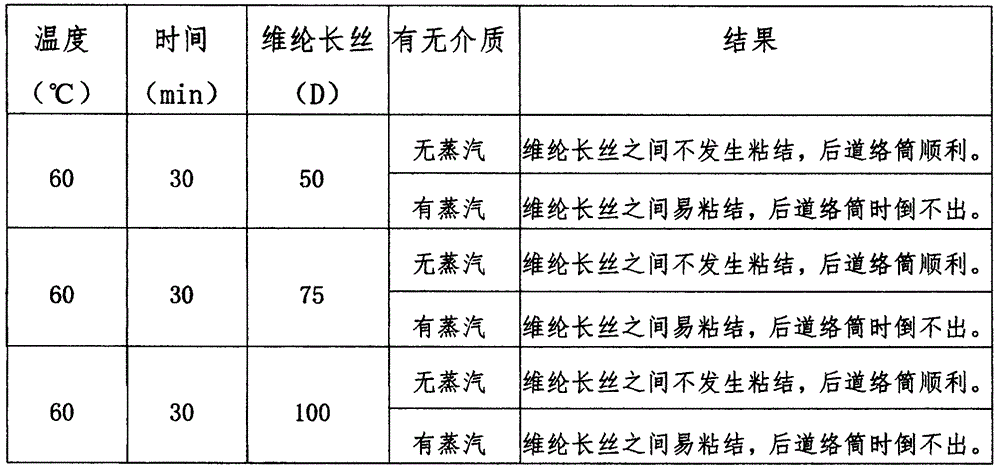

[0014] The wrapped twisted yarn production method of silk wrapped spandex includes doubling, wrapping and twisting, wrapping twisted yarn setting and precision winding, and before doubling, it also includes silkworm colored silk processing, and said silkworm colored silk The processing is to whiten and dye 23dtex silkworm silk f2 S 300, and then make it into a tube to become 23dtex silkworm silk f2S 300; and the silk is to combine 23dtex silkworm silk f2 S 300 and 50D vinylon filament Under the condition of yarn tension of 19CN, the untwisted combined yarn is synthesized into untwisted combined yarn; wrapping and twisting is to wrap the untwisted combined yarn on the wrapped yarn machine with 12CN wrapping tension to the surface of 20D spandex, and twist to become 1750 twists / Wrapped twisted yarn of rice, the drafting amount of 20D spandex is well controlled in the wrapped twisted process; the wrapped twisted yarn is shaped by dry steaming the wrapped twisted yarn, and the dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com