Drying and winding integrated device for silk processing

A kind of winding and integrated technology, which is applied in the direction of silk fiber production, delivery of filamentous materials, transportation and packaging, etc. It can solve the problems of complicated procedures, difficult quality assurance, and affecting silk quality, so as to shorten production time and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below according to the accompanying drawings.

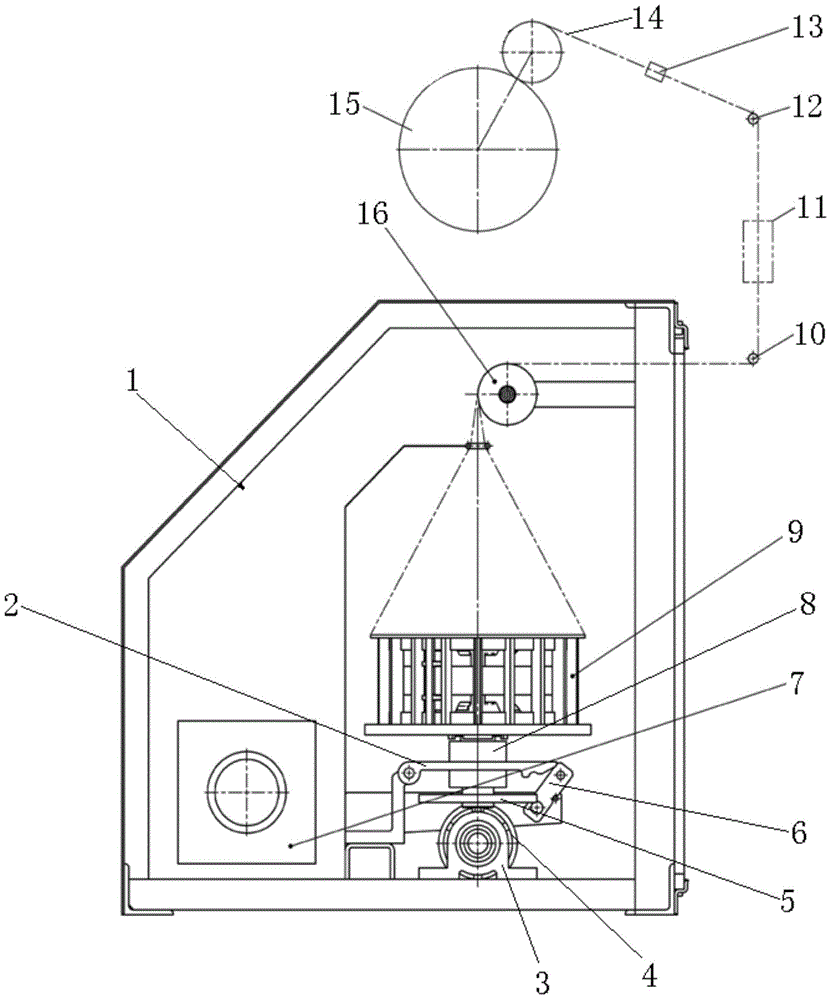

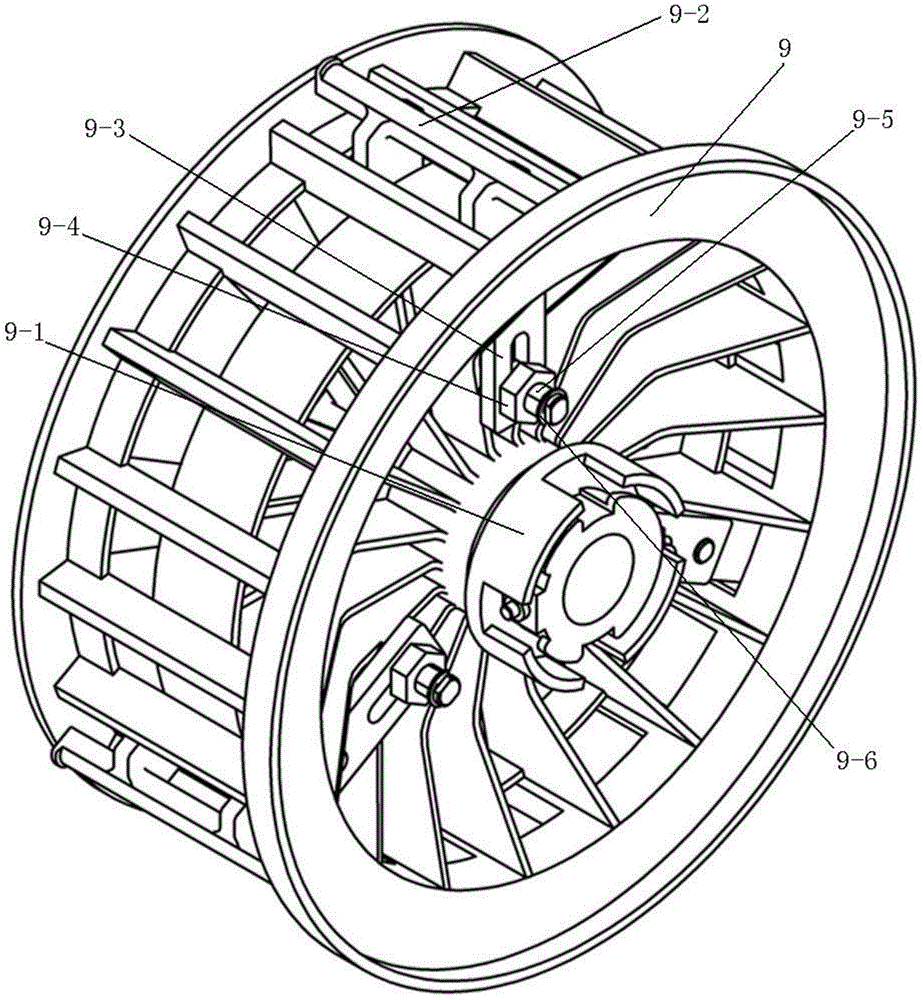

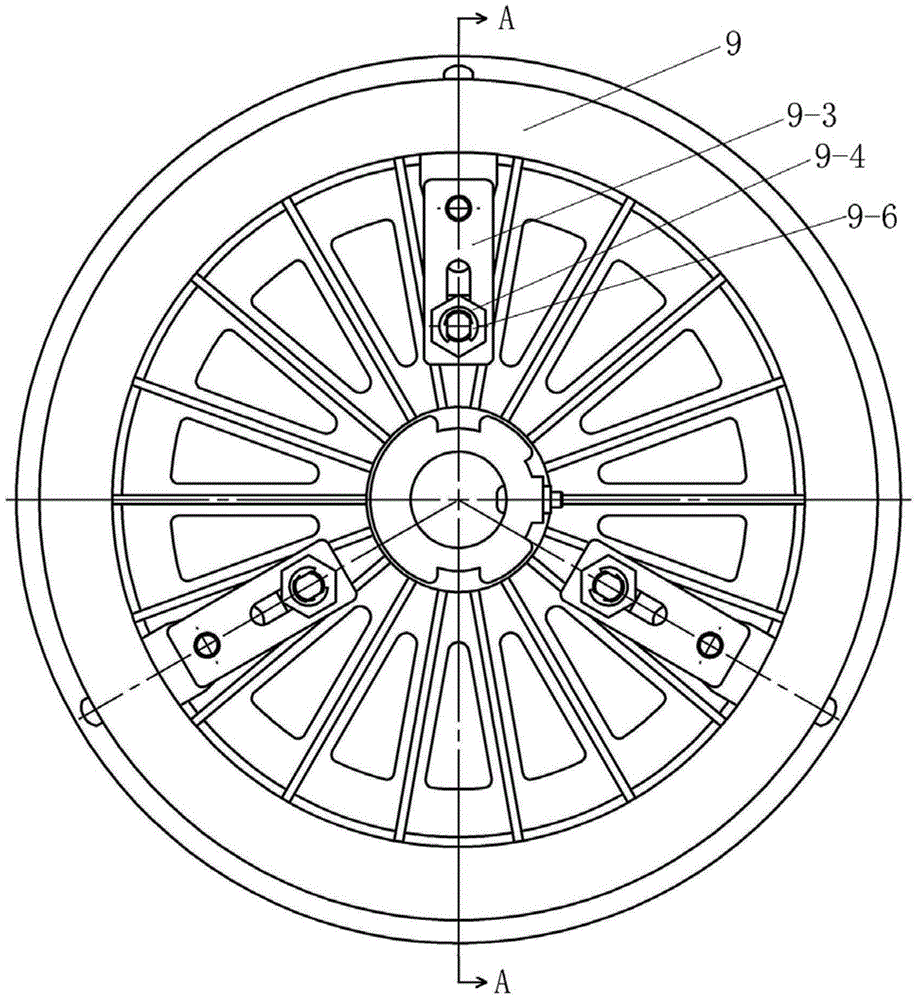

[0022] Such as figure 1 As shown, the two sides on the ground in the heat preservation studio 1 are provided with main shaft rotating seats 3 respectively, and the main shaft rotating seats 3 on both sides are connected by the main shaft, and a plurality of rotating wheels 4 are set on the main shaft. Connect the friction wheel 5, the central shaft of the friction wheel 5 is connected to the rotating shaft, the rotating shaft above the friction wheel 5 is sleeved with a bearing seat 8, and the rotating shaft above the bearing seat 8 adopts a bearing shaft to connect with the small wheel 9 ; There is a guide wheel 16 above the small Yu 9, and the guide wheel 16 is fixed on the side wall of the heat preservation studio 1;

[0023] The heat preservation studio 1 is provided with a tensioner 10 for winding, a wire sensor 11 , a glass rod 12 , a wire shifter 13 and a main wheel 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com