Flat plate brush plating experiment platform

An experimental platform and electric brush plating technology, applied in the field of electric brush plating, can solve the problems of uneven reciprocating speed of brush plating pen, uneven brush plating on the surface of flat workpieces, etc., and achieve the effect of uniform brush plating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

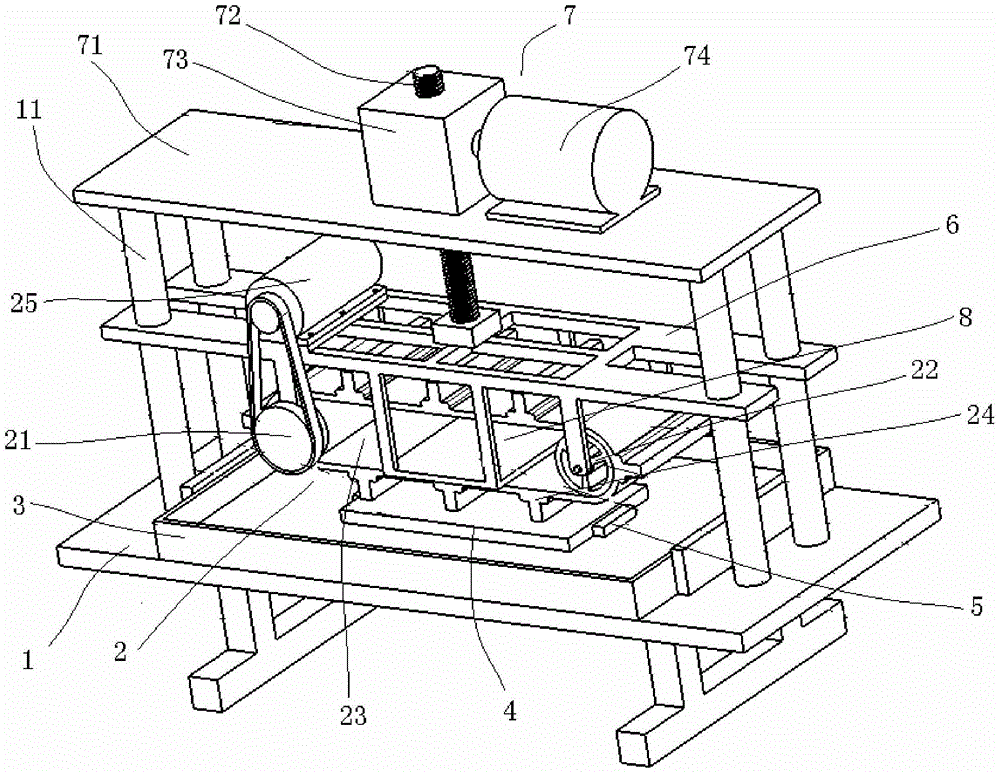

[0022] Used for brush plating experiments on flat workpieces, such as figure 1 As shown, a flat plate brush plating experiment platform according to a specific embodiment of the present invention includes: a workbench 1 , a brush plating device 2 , and a plating solution delivery device 3 . in:

[0023] The plating solution delivery device 3 is provided with on the workbench 1, the plating solution delivery device 3 is a plating solution pool, and the bottom of the plating solution pool is made of iron plate, and the plate workpiece 4 that needs to be brushed is placed on the bottom of the plating solution pool, The left and right sides of the workpiece 4 are respectively provided with magnetic blocks 5 for fixing the workpiece. The magnetic block 5 and the iron plate are mutually adsorbed, and the magnetic block 5 is fixed at a certain position, so that the workpiece 4 is also fixed at a certain position by the magnetic block 5 to prevent The workpiece 4 slides during the br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com