Method for preparing microfiber hemostatic collagen sponge

A technology of collagen sponge and microfiber, which is applied in medical science, absorbent pads, bandages, etc., can solve problems such as difficulty in maintaining the inherent shape, poor mechanical properties, and easy degradation, and achieve good hemostatic performance, efficient water absorption, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

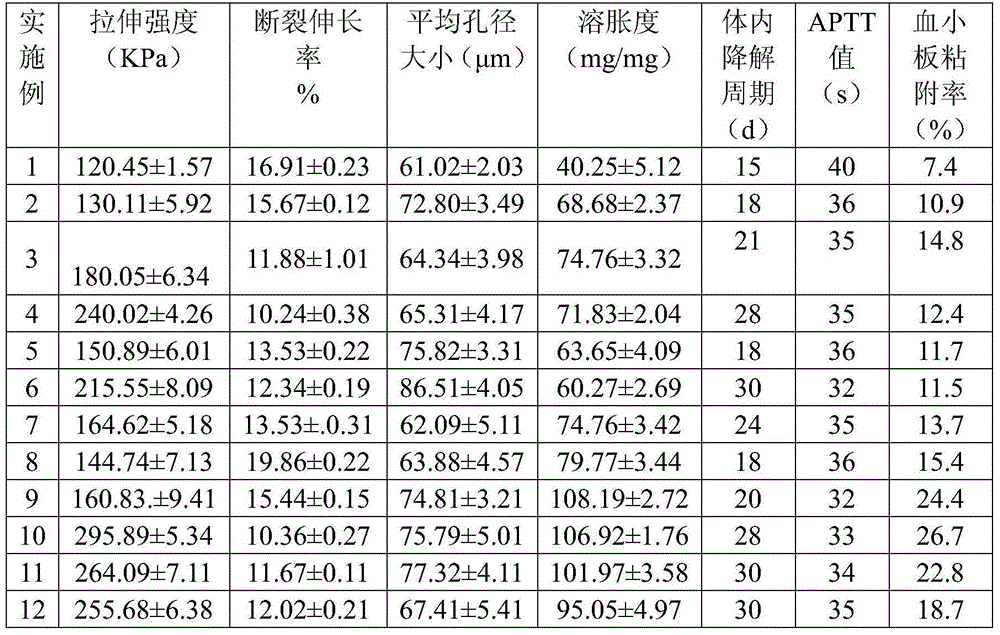

[0026] At 4°C, mix 0.5 mg / mL collagen acetate solution with 0.085M phosphate buffer at a volume ratio of 16:1, adjust pH to 5 with 0.1M NaOH solution, stir and mix well, and transfer to a 15°C water bath After 2 h, the solidified assembled collagen solution was centrifuged at 4000 rmp / min for 10 min, the supernatant was discarded, and the salt was removed by dialysis for 1 d. The assembled collagen solution was freeze-dried to make a sponge, which was cross-linked in a vacuum drying oven at 80°C for 24 hours to obtain a microfiber hemostatic collagen sponge. The properties of the obtained sponge are shown in Table 1.

Embodiment 2

[0028] At 4°C, mix 1 mg / ml collagen acetic acid solution with 0.09M phosphate buffer at a volume of 8:1, adjust pH to 6 with 0.1M NaOH solution, stir and mix well, and then transfer to a 20°C water bath. After 4 hours, the solidified collagen solution was centrifuged at 5000 rmp / min for 10 minutes, the supernatant was discarded, and the salt was removed by dialysis for 2 days. The assembled collagen solution was freeze-dried to form a sponge, and cross-linked in a vacuum drying oven at 100°C for 24 hours to obtain a microfiber hemostatic collagen sponge. The properties of the obtained sponge are shown in Table 1.

Embodiment 3

[0030] At 4°C, mix 2 mg / ml collagen acetic acid solution with 0.075M phosphate buffer at a volume of 4:1, adjust pH to 7 with 0.1M NaOH solution, stir and mix well and transfer to a 25°C water bath. After 6 h, the solidified assembled collagen solution was centrifuged at 6000 rmp / min for 10 min, the supernatant was discarded, and the salt was removed by dialysis for 3 d. The assembled collagen solution was freeze-dried to make a sponge, and cross-linked in a vacuum drying oven at 110° C. for 24 hours to obtain a microfiber hemostatic collagen sponge. The properties of the obtained sponge are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com