Polybutadiene rubber, preparation method of polybutadiene rubber and oil-extended rubber

A technology of polybutadiene rubber and oil-extended rubber, which is applied in the field of polybutadiene rubber, can solve the problem of incomplete conversion of monomers, and achieve the effect of wide molecular weight distribution and good rubber processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

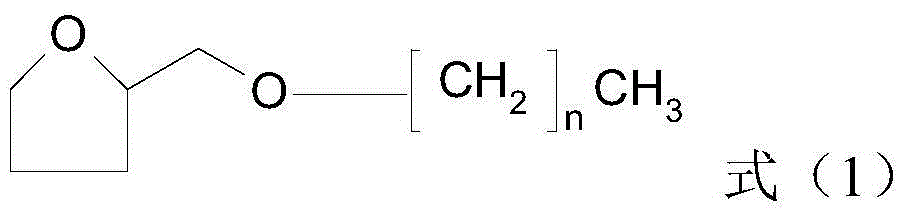

[0018] The preparation method of polybutadiene rubber provided by the present invention comprises: under anion polymerization condition, 1,3-butadiene, solvent and polarity regulator are from the first kettle of the continuous polymerization reaction device that comprises a plurality of serial reaction kettles Introduce continuously, and carry out continuous polymerization in each still of described continuous polymerization reactor successively, wherein, this method also comprises initiator from described first still and at least one reaction still after described first still is introduced, and The temperature of anionic polymerization is controlled at 90-150°C.

[0019] According to the present invention, as long as the initiator is introduced from the first tank and at least one reaction tank after the first tank at a polymerization temperature of 90-150° C., the conversion rate of the monomer can be increased and the polymer yield can be increased. Molecular weight distrib...

Embodiment 1

[0052] This embodiment is used to illustrate the polybutadiene rubber provided by the present invention and its preparation method.

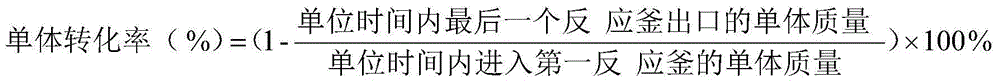

[0053] The polymerization reaction was carried out in three 5-liter polymerization reactors connected in series. Under the protective atmosphere of high-purity nitrogen, the residence time of materials in a single tank is 15 minutes, the reaction temperature in the polymerization tank is controlled at 130±1°C, and the pressure is controlled at 0.8±0.05MPa (gauge pressure). The feed rate of each reaction material at the bottom of the first kettle is: mixed solvent (a mixture of cyclohexane and n-hexane with a weight ratio of 88:12) 11544g / h, 1,3-butadiene 3256g / h, n-butyl Lithium 0.776g / h, ethyl tetrahydrofurfuryl ether 5.77g / h and 1,2-butadiene 0.98g / h. Add n-butyl lithium to the bottom of the third kettle at 0.041 g / h. A terminator isopropanol was added at 0.77 g / h at the outlet of the third kettle to terminate the reaction, and an anti-aging...

Embodiment 2

[0058] This embodiment is used to illustrate the polybutadiene rubber provided by the present invention and its preparation method.

[0059]The polymerization reaction was carried out in three 5-liter polymerization reactors connected in series. Under the protective atmosphere of high-purity nitrogen, the residence time of materials in a single tank is 20 minutes, the reaction temperature in the polymerization tank is controlled at 120±1°C, and the pressure is controlled at 0.7±0.05MPa (gauge pressure). The feed rate of each reaction material at the bottom of the first kettle is: raffinate 9435g / h, 1,3-butadiene 1665g / h, n-butyllithium 0.254g / h, ethyl tetrahydrofurfuryl ether 4.72g / h h and 1,2-butadiene 0.5g / h. Add n-butyllithium to the bottom of the third kettle at 0.05 g / h. A terminator isopropanol was added at 0.28 g / h at the outlet of the third kettle to terminate the reaction, and an anti-aging agent Irganox1520 of 0.2% by monomer weight was added to obtain a polybutadi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com