A kind of preparation method of trans-1,2-cyclohexanediol diacetate

A technology of cyclohexanediol diacetate and cyclohexanediol is applied in the field of preparation of trans-1,2-cyclohexanediol diacetate, which can solve the problem of restricting large-scale industrial production of MCA and high production cost of MCA , long production process route and other problems, to achieve the effect of excellent organic solubility, low synthesis cost and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

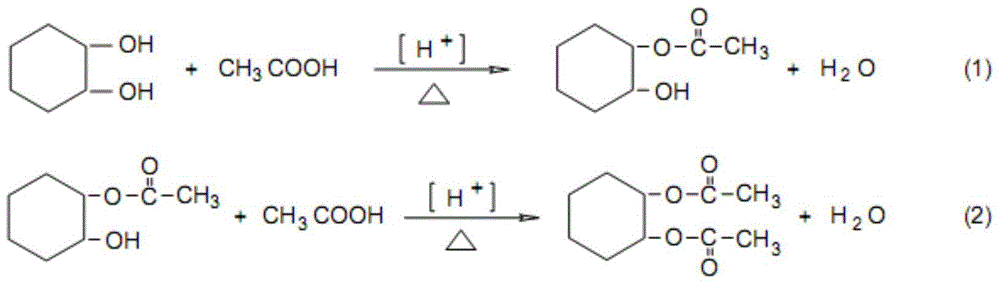

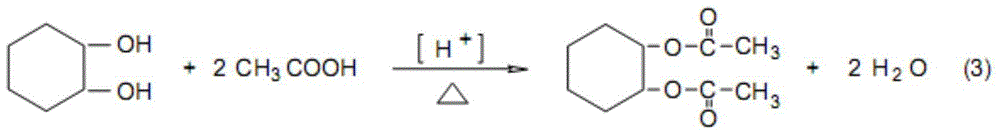

[0036] A preparation method of trans-1,2-cyclohexanediol diacetate of the present invention comprises the following steps:

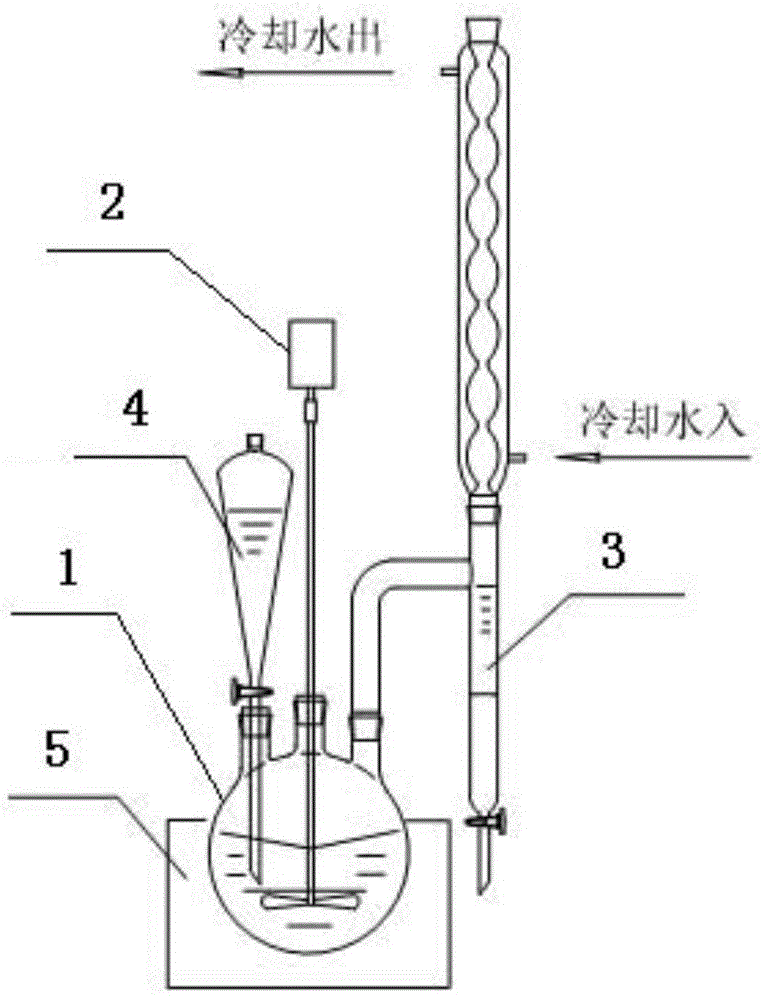

[0037] (1) if figure 1 Shown, in the 1000ml four-necked flask 1 that has mechanical stirrer 2 and reflux separator 3 (the opening that has thermometer is in figure 1 116 g (1 mol) of a sample of trans-1,2-cyclohexanediol and 8.0 g of esterification catalyst p-toluenesulfonic acid were added, and then 200 g of reaction solvent methylcyclohexane was added. The four-necked flask 1 was placed in an electric heating mantle 5 to heat up to completely dissolve the trans-1,2-cyclohexanediol and the esterification catalyst.

[0038] In this example, trans-1,2-cyclohexanediol is obtained by hydrolysis reaction of epoxycyclohexane recovered from the by-product light oil in the production process of cyclohexanone under acidic conditions; the hydrolysis reaction The post-treatment of liquid includes stratification, neutralization, concentration, crystallization and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com