A kind of composite mineral powder water retention enhancer

A technology of composite ore and reinforcing agent, applied in the field of building materials, can solve the problems of insufficient functions, powdered mortar, and large dosage, etc., and achieve the effect of improving mortar performance, good cohesion, and low addition amount.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

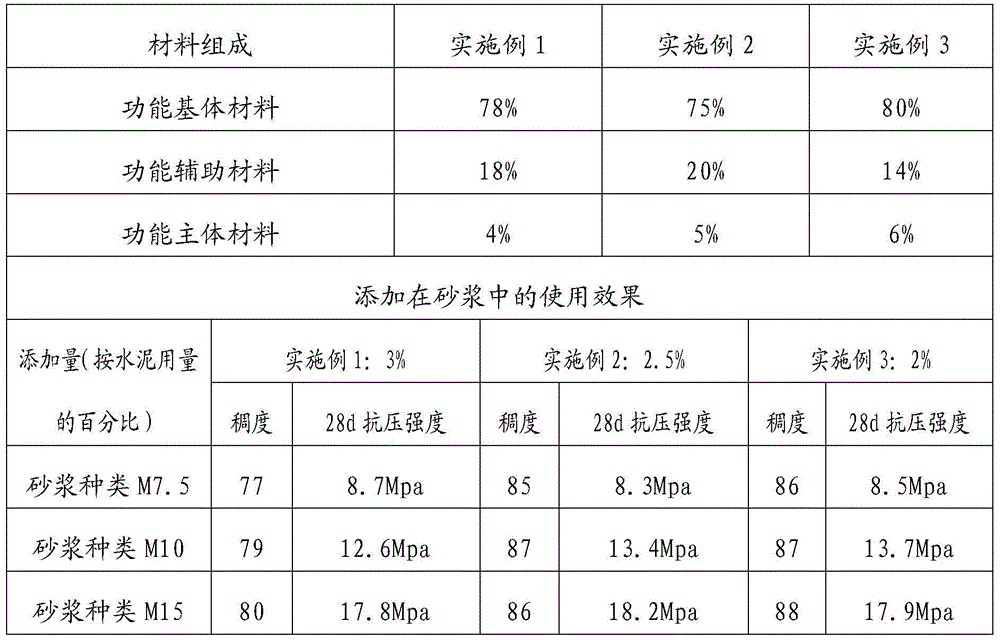

Embodiment 1

[0027] A composite mineral powder water retention enhancer, based on the percentage of the total weight of the raw materials, is composed of the following raw materials: 78% of functional matrix materials, 18% of functional auxiliary materials, and 4% of functional main materials.

[0028] The functional matrix material is calculated as a percentage of the total weight of the raw materials and consists of the following raw materials: attapulgite 8%, kaolin 12%, zeolite powder (above 400 mesh, zeolite content 60% or more) 24%, bentonite 11%, 22% silica powder, 23% vermiculite powder;

[0029] The functional auxiliary material is calculated as a percentage of the total weight of the raw materials and is composed of the following raw materials: 19% sodium gluconate, 21% fatty alcohol polyoxyethylene ether sulfate, 9% sodium tripolyphosphate, and 12% zinc stearate , Glass fiber (3mm chopped fiber engineering fiber) 14%, wood fiber 25%;

[0030] The functional main body material is calcu...

Embodiment 2

[0033] A composite mineral powder water retention enhancer, based on the percentage of the total weight of the raw materials, is composed of the following raw materials: 75% of the functional base material, 20% of the functional auxiliary material, and 5% of the functional main material.

[0034] The functional matrix material is calculated as a percentage of the total weight of the raw materials and consists of the following raw materials: attapulgite 8%, kaolin 12%, zeolite powder (above 400 mesh, zeolite content 60% or more) 24%, bentonite 11%, 22% silica powder, 23% vermiculite powder;

[0035] The functional auxiliary material is calculated as a percentage of the total weight of the raw materials and is composed of the following raw materials: 19% sodium gluconate, 21% fatty alcohol polyoxyethylene ether sulfate, 9% sodium tripolyphosphate, and 12% zinc stearate , Glass fiber (3mm chopped fiber engineering fiber) 14%, wood fiber 25%;

[0036] The functional main body material i...

Embodiment 3

[0039] A composite mineral powder water retention enhancer, calculated as a percentage of the total weight of the raw materials, is composed of the following raw materials: 80% of functional matrix materials, 14% of functional auxiliary materials, and 6% of functional main materials.

[0040] The functional matrix material is calculated as a percentage of the total weight of the raw materials and consists of the following raw materials: attapulgite 8%, kaolin 12%, zeolite powder (above 400 mesh, zeolite content 60% or more) 24%, bentonite 11%, 22% silica powder, 23% vermiculite powder;

[0041] The functional auxiliary material is calculated as a percentage of the total weight of the raw materials and is composed of the following raw materials: 19% sodium gluconate, 21% fatty alcohol polyoxyethylene ether sulfate, 9% sodium tripolyphosphate, and 12% zinc stearate , Glass fiber (3mm chopped engineering fiber) 14%, wood fiber 25%;

[0042] The functional main body material is calculat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com