A kind of ceramic panel with water permeability and water retention performance and preparation method thereof

A technology of ceramics and panels, which is applied in the field of ceramic panels and its preparation, can solve the problems of not being well utilized, and achieve the effects of improving rainwater drainage, reducing burdens, and having a long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

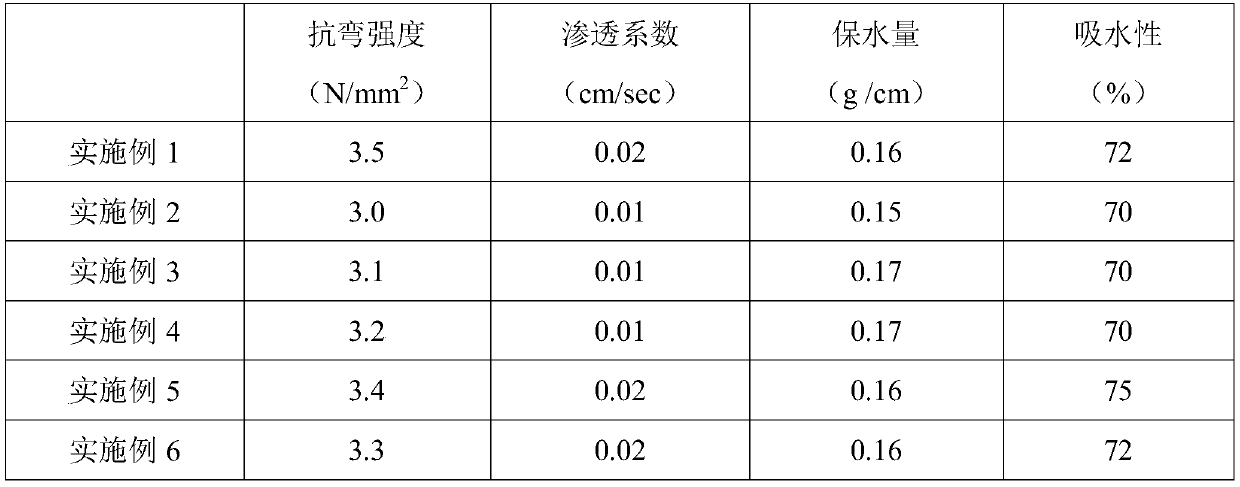

Examples

Embodiment 1

[0023] A method for preparing a ceramic panel with water-permeable and water-retaining properties, characterized in that 45 parts by weight of raw material glassy slag, 45 parts of clay minerals, 9 parts of rice husks, 18 parts of water, carboxymethyl cellulose 10 parts are mixed, kneaded, and then rolled out in a cylindrical shape with a vacuum kneader, made on a flat plate using a roller rolling machine, after being irradiated by far infrared rays, dried in a drying oven, and finally sintered at a temperature in the range of 1000°C. After sintering, pass on the surface Grinding with sandpaper, etc., to obtain a finished product.

[0024] The particle size of the rice husk is less than 1mm, the particle size of the glassy slag is less than 0.5mm, and the glassy slag with a particle size of less than 0.15mm accounts for 20% of the total glassy slag weight.

[0025] The glassy slag is garbage molten slag.

Embodiment 2

[0027] A method for preparing a ceramic panel with water-permeable and water-retaining properties, characterized in that 20 parts by weight of raw material glassy slag, 70 parts of clay minerals, 0.5 parts of rice husk, 20 parts of water, carboxymethyl cellulose 10 parts are mixed, kneaded, and then rolled out in a cylindrical shape with a vacuum kneader, made on a flat plate using a roller rolling machine, after being irradiated by far infrared rays, dried in a drying oven, and finally sintered at a temperature in the range of 900°C. After sintering, pass on the surface Grinding with sandpaper, etc., to obtain a finished product.

[0028] The particle size of the rice husk is 0.8mm, the particle size of the glassy slag is less than 0.5mm, and the glassy slag with a particle size of less than 0.15mm accounts for 10% of the total glassy slag weight.

[0029] The glassy slag is a mixture of garbage melting slag and sewage sludge melting slag.

Embodiment 3

[0031] A method for preparing a ceramic panel with water permeability and water retention performance, characterized in that 70 parts by weight of raw material glassy slag, 20 parts of clay minerals, 10 parts of rice husk, 15 parts of water, and 15 parts of water glass are mixed , kneading, and then use a vacuum kneader to roll out in a cylindrical shape, and use a roller rolling machine on a flat plate to make it. After being irradiated by far-infrared rays, it is dried in a drying oven, and finally sintered at a temperature in the range of 1200 ° C. After sintering, use sandpaper on the surface. Tried to get the finished product.

[0032] The particle size of the rice husk is less than 1mm, the particle size of the glassy slag is less than 0.5mm, and the glassy slag with a particle size of less than 0.15mm accounts for 40% of the total glassy slag weight.

[0033] The glassy slag is a favorable quality slag generated during metal smelting.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com