Gypsum powder, preparation method thereof, and application of gypsum powder in sculptures and unfired pottery clay

A technology of gypsum powder and starch, applied in the field of gypsum powder, can solve the problems of poor bending toughness, poor weather resistance, fast curing speed and unfavorable kneading of gypsum powder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

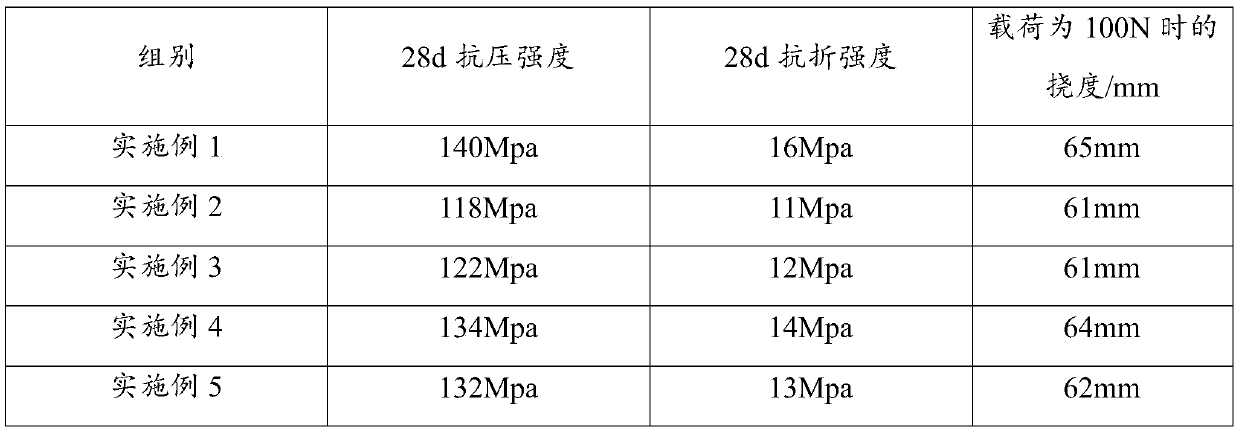

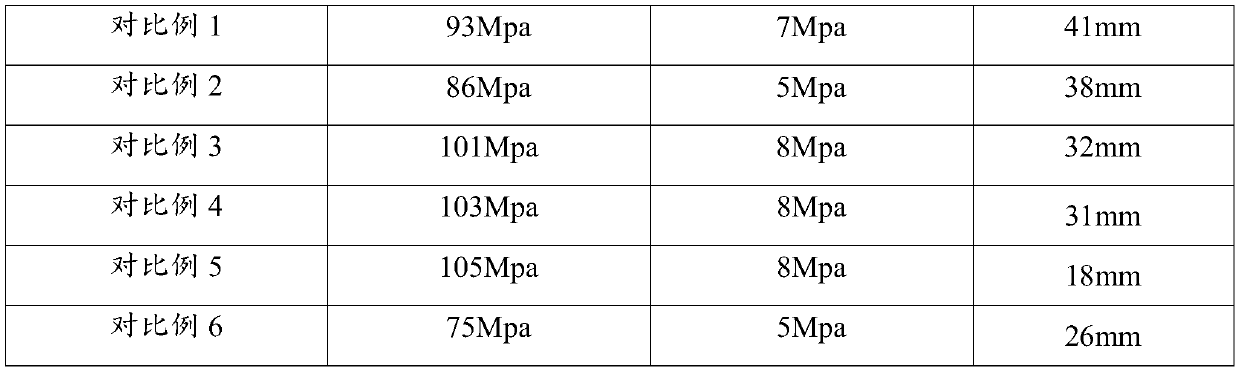

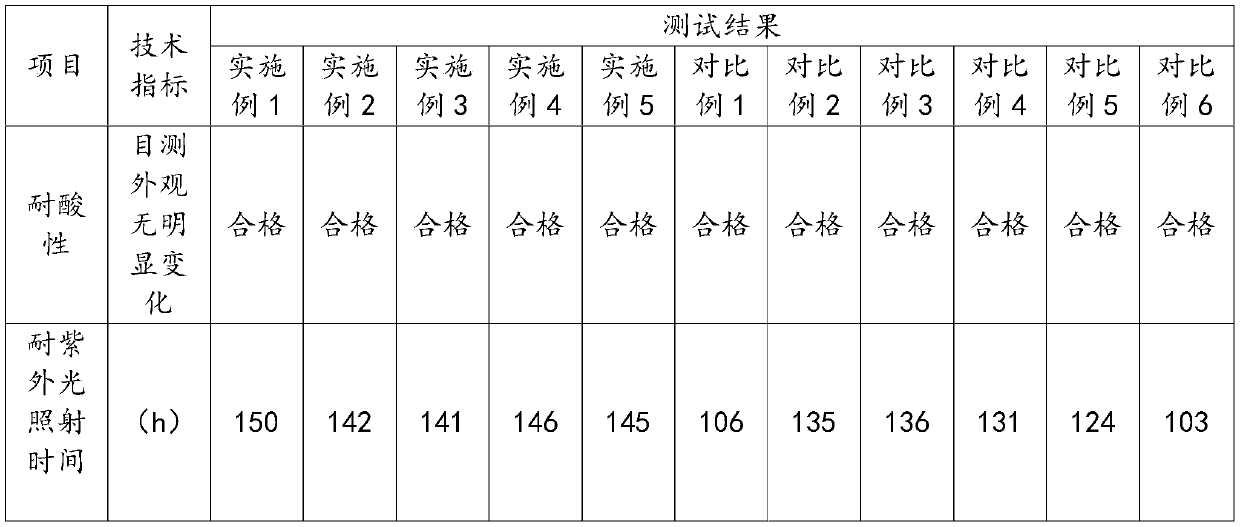

Examples

Embodiment 1

[0020] A gypsum powder, comprising the following components in parts by weight: 75 parts of alpha gypsum powder, 18 parts of filler (white marble powder), 0.35 parts of dispersant (HQ-F20), 3.5 parts of dispersible latex powder, 7 parts of retarder 7 parts of modified starch, 10 parts of polyvinyl alcohol PVA powder, 5 parts of cellulose ether, 1.3 parts of glass staple fiber (or 0.13 part of chemical fiber staple fiber).

Embodiment 2

[0022] A kind of gypsum powder, comprising the following components in parts by weight: 70 parts of beta gypsum powder, 20 parts of filler (quartz sand), 0.2 part of dispersant (HQ-F20), 2 parts of dispersible latex powder, retarder 5 parts, 5 parts of modified starch, 8 parts of polyvinyl alcohol PVA powder, 1 part of cellulose ether, 1 part of glass staple fiber (or 0.1 part of chemical fiber staple fiber).

Embodiment 3

[0024] A gypsum powder, comprising the following components in parts by weight: 80 parts of alpha gypsum powder, 15 parts of filler (sandstone), 0.5 part of dispersant (HQ-20F), 5 parts of dispersible latex powder, and 10 parts of retarder , 10 parts of modified starch, 12 parts of polyvinyl alcohol PVA powder, 10 parts of cellulose ether, 2 parts of glass staple fiber (or 0.2 part of chemical fiber staple fiber).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com