Modularly assembled plate type catalysis reaction device and method

A technology of photocatalytic reaction and catalytic reactor, which is applied in chemical instruments and methods, water treatment of special compounds, light water/sewage treatment, etc., can solve the problems of insufficient research on new photocatalytic reactors of photocatalytic reactors, and achieve transparent Enhanced light and astigmatism properties, avoid material waste, increase the effect of oxygen molecules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

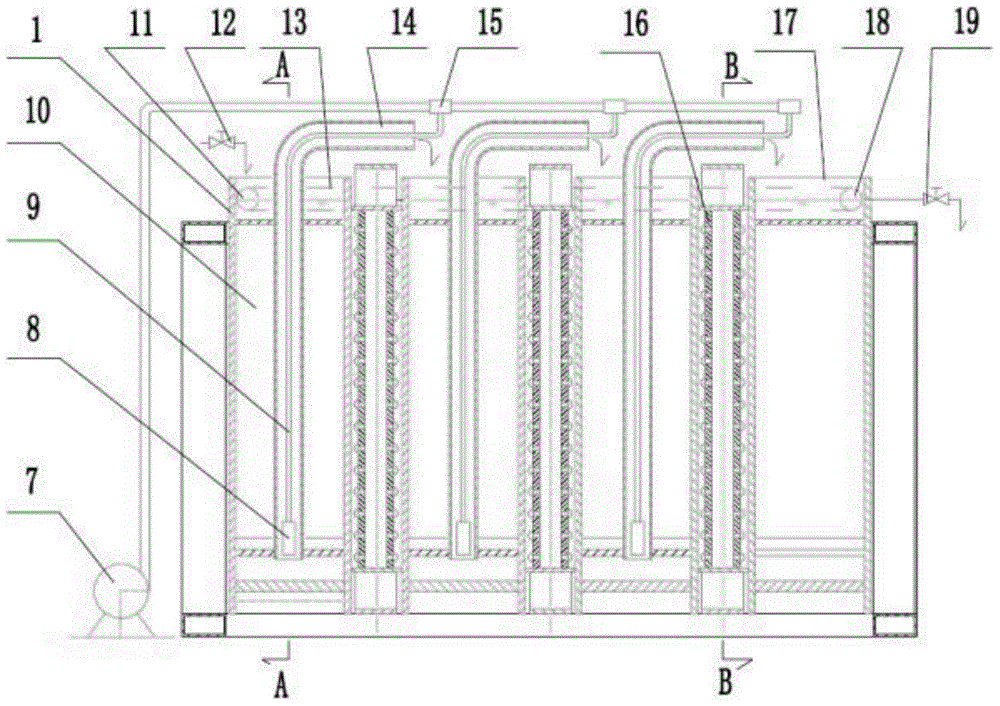

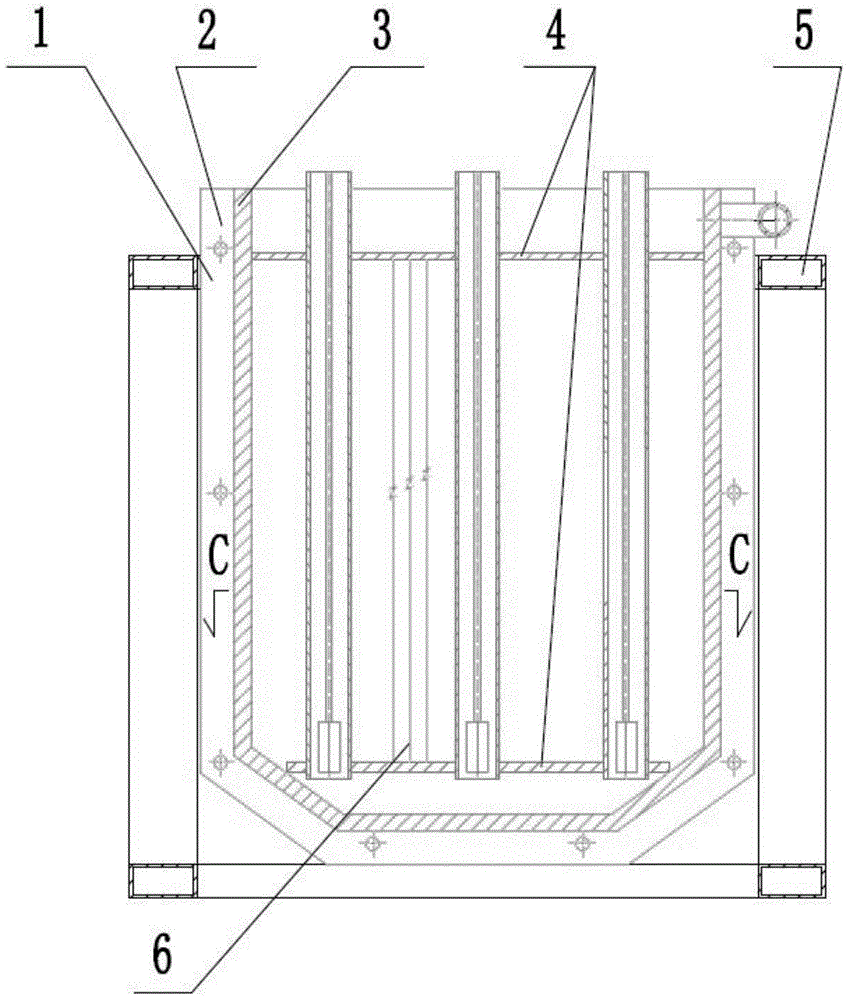

[0016] The modularly assembled plate-type photocatalytic reaction device of the present invention includes a catalytic reactor, a light source system and a catalyst carrier component.

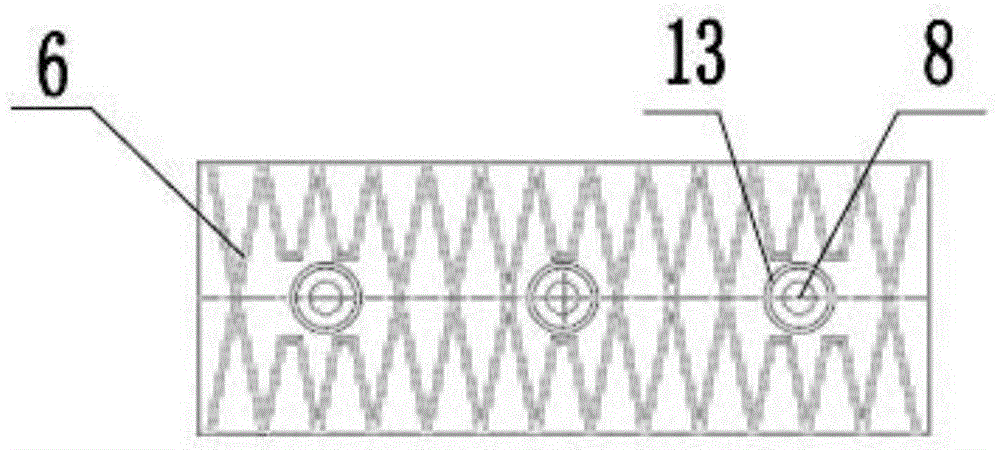

[0017] The catalytic reactor is a plate-type box, made of a U-shaped tank body 3 made of mirror stainless steel plate, and the two sides are covered with a quartz glass plate 1, and a U-shaped sealing rubber plate is sandwiched between the U-shaped tank body 3 and the quartz glass plate 1, The quartz glass plates on both sides are clamped and fixed by several fasteners 2 to form a plate-type box of the catalytic reactor; several liquid extraction tubes 14 with openings at both ends are placed in the catalytic reactor box in an inverted L shape through the mesh fixing plate 4 In the body, one end of the air delivery pipe 9 is connected to the air pump 7 through the air control valve 15, and the other end is connected to the air release head 8, and the air release head is suspended in the liquid e...

Embodiment 2

[0024] The TiO on the surface of the glass fiber matrix mesh sheet 2 The photocatalytic material is TiO doped with Ag nanoparticles 2 Thin film catalyst:

[0025] The conditions are as follows: tetra-n-butyl titanate is used as titanium source, nitric acid and acetylacetone are used as hydrolysis inhibitors, deionized water is used as hydrolysis agent, and polyethylene glycol and 1,5-pentanediol are additives.

[0026] Pipette 4 ml of tetra-n-butyl titanate, dissolve it in 1 ml of acetylacetone and stir for 0.5 hour to prepare solution A. Another solution B was obtained by dissolving 1 g of polyethylene glycol, 0.25 g of 1,5-pentanediol, and 0.7 g of water in 32.5 ml of ethanol. Solution B was slowly added dropwise to solution A and stirred for 1 hour, and an appropriate amount of concentrated nitric acid was added to adjust the acidity to obtain a precursor sol.

[0027] Immerse the glass fiber matrix mesh in the prepared sol, and finally, put it in a muffle furnace and bake...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com