Technical method for producing feed-grade zinc sulfate in environment-friendly manner by electrolytic zinc slag

A process method and technology for electrolysis of zinc, applied in directions such as zinc sulfate, can solve the problems of high energy consumption, high raw material cost, unenvironmental production process, etc., and achieve the effects of low energy consumption, high solution cost, and simple production process flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

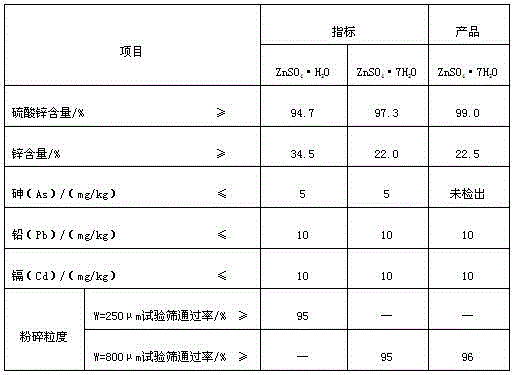

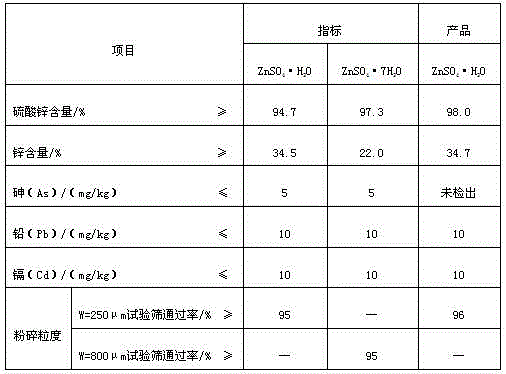

Examples

Embodiment 1

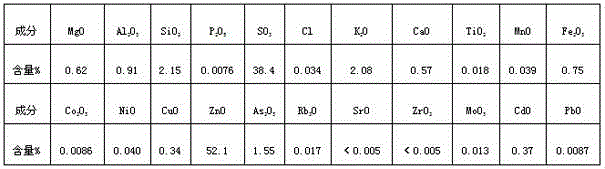

[0029] (1) Select the electrolytic zinc waste residue as shown in Table 1, add it and water into the primary reaction tank at a mass ratio of 1:3, stir at a speed of 90r / min, and inject steam into the material to make the material The temperature was heated to 80°C, and the temperature was kept and stirred for 1.5 hours, and the pH of the obtained solution was 1.5;

[0030] (2) Add saturated lime milk supernatant dropwise to the primary reaction tank, adjust the pH of the solution to 5.0, continue to stir for 30 minutes, and age for 15 minutes;

[0031] (3) Use a vacuum pump to pump out the materials in the primary reaction tank, and use a plate and frame filter press to separate the solid from the liquid. The resulting filter residue is washed with water and treated as solid calcium iron slag to the brick factory, and the filtrate enters the next channel process, washing water is reused as water for dissolving electrolytic zinc waste residue;

[0032] (4) Pump the filtrate i...

Embodiment 2

[0040] (1) Select the electrolytic zinc waste residue as shown in Table 1, add it and water into the primary reaction tank at a mass ratio of 1:4, stir at a speed of 70r / min, and inject steam into the material to make the material The temperature was heated to 70°C, and the temperature was kept and stirred for 2 hours, and the pH of the obtained solution was 2.0;

[0041] (2) Add saturated lime milk supernatant dropwise to the primary reaction tank, adjust the pH of the solution to 5.1, continue to stir for 1 hour, and age for 30 minutes;

[0042] (3) Use a vacuum pump to pump out the materials in the primary reaction tank, and use a plate and frame filter press to separate the solid from the liquid. The resulting filter residue is washed with water and treated as solid calcium iron slag to the brick factory, and the filtrate enters the next channel process, washing water is reused as water for dissolving electrolytic zinc waste residue;

[0043] (4) Pump the filtrate into th...

Embodiment 3

[0051] (1) Select the electrolytic zinc waste residue as shown in Table 1, add it and water to the primary reaction tank at a mass ratio of 1:2, stir at a speed of 80r / min, and inject steam into the material to make the material The temperature was heated to 60°C, and the temperature was kept and stirred for 1.7 hours, and the pH of the obtained solution was 1.5;

[0052] (2) Add saturated lime milk supernatant dropwise to the primary reaction tank, adjust the pH of the solution to 4.5, continue to stir for 0.6 hours, and age for 20 minutes;

[0053] (3) Use a vacuum pump to pump out the materials in the primary reaction tank, and use a plate and frame filter press to separate the solid from the liquid. The resulting filter residue is washed with water and treated as solid calcium iron slag to the brick factory, and the filtrate enters the next channel process, washing water is reused as water for dissolving electrolytic zinc waste residue;

[0054] (4) Pump the filtrate into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com