Storage bin provided with spiral slideway

A technology of spiral slides and storage bins, applied in the direction of containers, packaging, transportation and packaging, etc., can solve the problems of limited filling volume, unreasonable structure, occupation, etc., and achieve the goal of reducing broken rate, low manufacturing cost and preventing broken Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

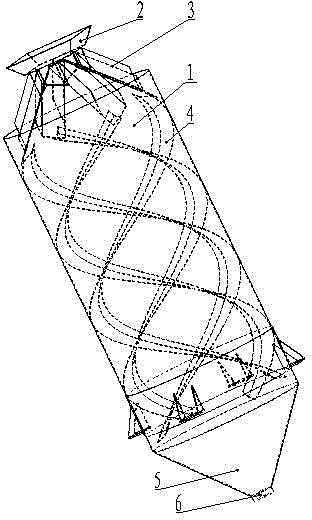

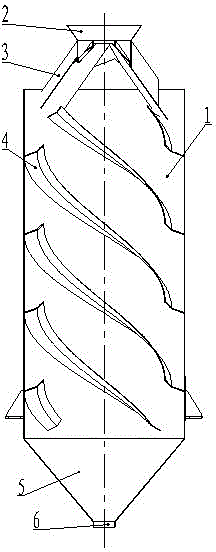

[0021] Invention Embodiment 1: Circular section silo with spiral slideway

[0022] The embodiment of the present invention provides a circular section silo with a spiral slideway, including a cylindrical shell 1, a material inlet 2, a material distribution chute 3, a spiral slideway 4, a conical cylinder body 5 and a discharge port 6 Wait. It is characterized in that the lower part of the material inlet 2 is connected with the material distribution chute 3 , and the lower part of the material distribution chute 3 is connected with the spiral slideway 4 in the cylindrical shell 1 . For a larger storage bin, in order to ensure a larger delivery volume, a plurality of spiral slideways 4 need to be evenly distributed along the circumference of the cylindrical shell 1 of the silo, and the spiral slideways 4 are evenly distributed on the inner wall of the cylindrical shell 1 . The helix angle of the spiral slideway 4 is slightly greater than or equal to the dynamic repose angle of ...

Embodiment 2

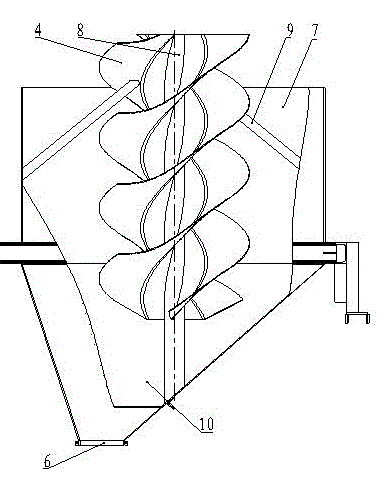

[0024] Invention Example 2: Square-section bunker with spiral slideway

[0025] The embodiment of the present invention provides a square-section silo with a spiral slideway, including a square-section silo shell 7, a spiral slideway 4, a central column 8, a diagonal brace 9, a bottom square cone shell 10 and an outlet Material port 6 and so on. It is characterized in that the central column 8 is fixedly connected to the middle of the silo shell, the bottom of the central column 8 is welded to the bottom square cone shell 10, and is supported and fixed by the diagonal bracing tube 9, and the height of the central column 8 is higher than the upper edge of the silo. The spiral slideway 5 is uniformly welded on the center column 8 and extends to the bottom of the center column 8 . One end of the diagonal bracing pipe 9 is supported on the spiral slideway 5, and the other end is supported on the inner wall of the silo shell.

[0026] The discharge process of fragile materials in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com