Quantitative piling and counting method and device for independently controlling channel to output articles

An independent control and quantitative stacking technology, which is applied in transportation and packaging, packaging automatic control, packaging, etc., can solve the problem of overflow of items, reduce the chance of overflow, reduce the possibility of overflow, and increase production capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

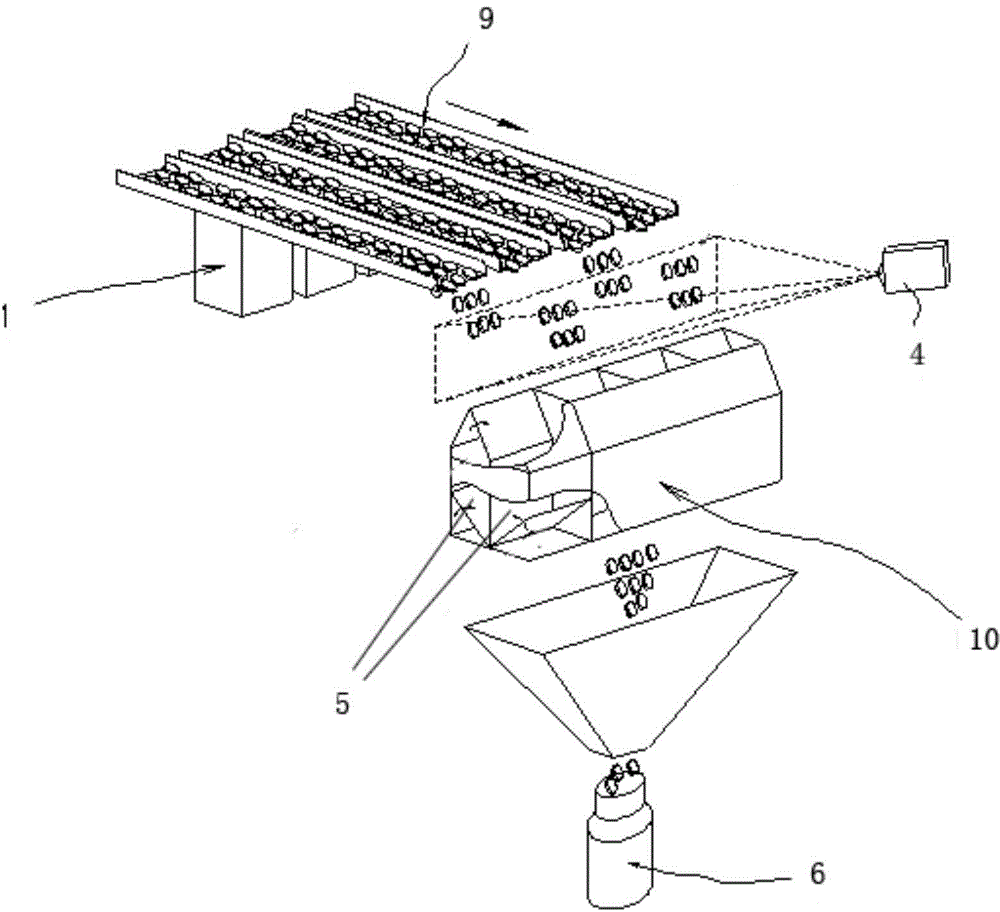

[0070] like figure 1 As shown, a quantitative sorting and counting device for outputting articles through independent control channels includes at least two side-by-side vibrating plates 9 for transporting multiple items, and the items are output at the end of the vibrating plates 9;

[0071] The driver 1 is used to control the movement or stop of each vibrating disc 9, and make the items output by the vibrating disc 9 form a pile of items;

[0072] The counting device 4 is used to accurately count the number of items in the stack of items output by each vibrating plate 9 in an image-capturing manner;

[0073] The temporary storage bin 5 is used to receive the pile of items output by the vibrating plate 9;

[0074] The storage 6 is used to receive the items in a combined temporary storage bin 5 whose total number of items is the same as the target number.

[0075] The drivers 1 are provided in one-to-one correspondence with the vibrating plates 9 , and each vibrating plate 9...

Embodiment 2

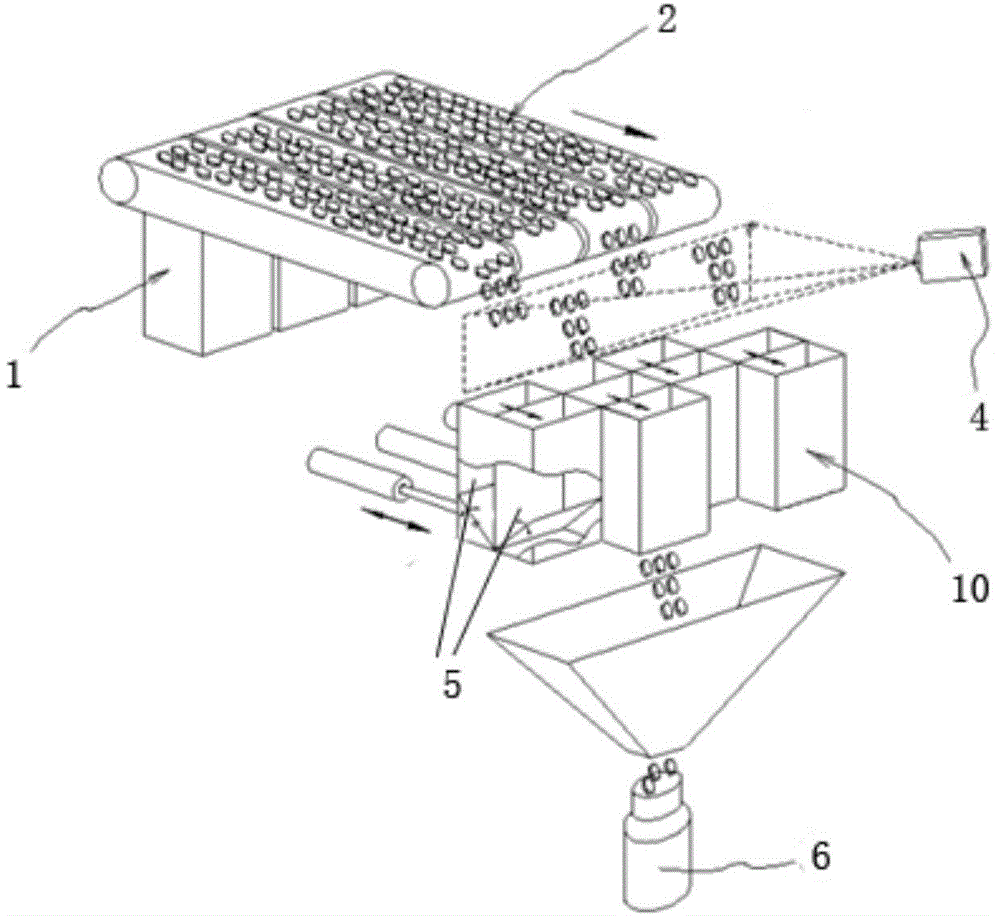

[0078] like figure 2 As shown, a quantitative sorting and counting device for independently controlling channel output items, including at least two conveyor belts 2 side by side, used to transport multiple items, and output items at the end of the conveyor belt 2;

[0079] The driver 1 is used to control the movement or stop of each conveyor belt 2, and make the items output by the conveyor belt 2 form an item pile;

[0080] The image-taking and counting device 4 is used for accurately counting the number of articles in the article pile output by each conveyor belt 2 in an image-taking manner;

[0081] Temporary storage bin 5, used to receive the pile of items output by conveyor belt 2;

[0082] The storage 6 is used to receive the items in a combined temporary storage bin 5 whose total number of items is the same as the target number.

[0083] The driver 1 is provided in one-to-one correspondence with the conveyor belts 2 , and each conveyor belt 2 is driven by the corres...

Embodiment 3

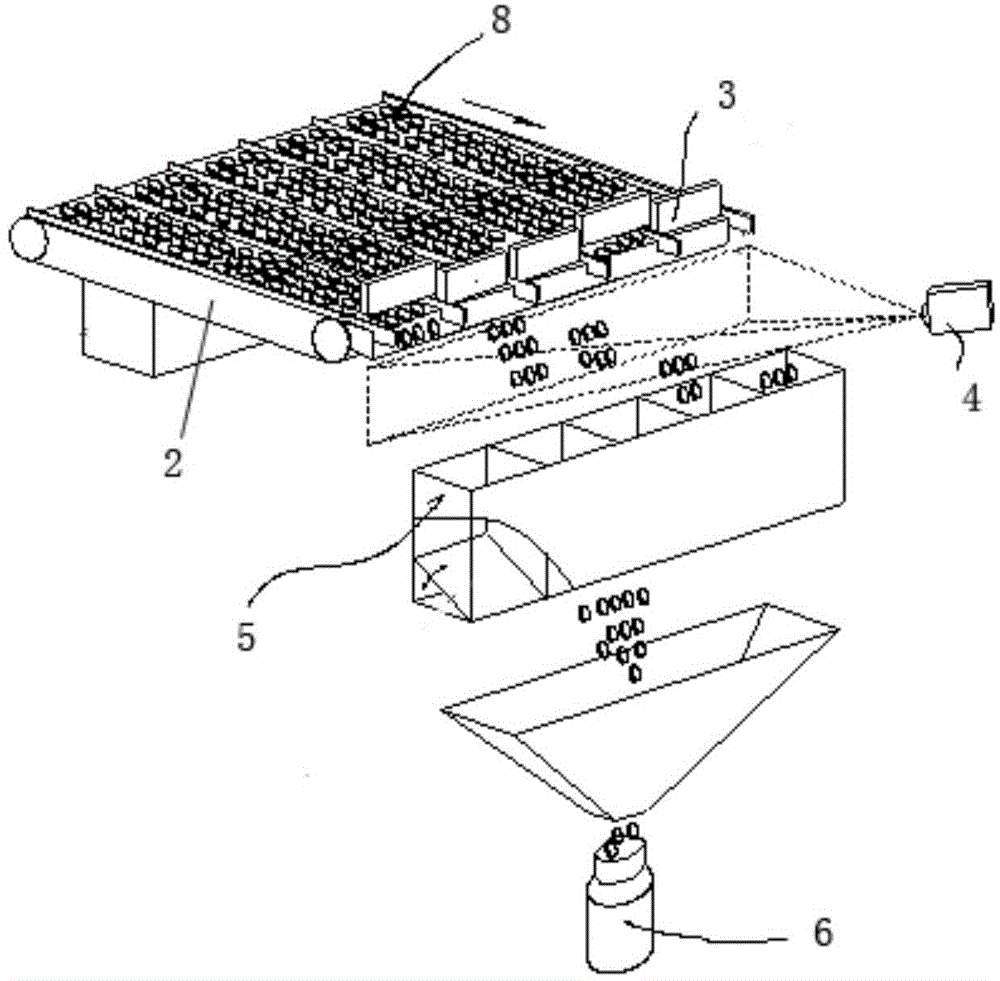

[0086] like image 3 As shown, a quantitative sorting and counting device for independently controlling channel output items includes at least one conveyor belt 2, and the conveying surface of the conveyor belt 2 is divided into at least two side-by-side partitions for conveying multiple A conveying channel 8 of an article, and the article is output at the end of the conveyor belt 2;

[0087] The output end of each conveying channel 8 is respectively provided with a gate 3, which is opened or closed by the gate 3, controls each conveying channel 8 to output articles or stops outputting articles, and makes the articles output by each conveying channel 8 form a pile of articles;

[0088] The image-taking and counting device 4 is used to accurately count the number of items in the item stack output by each conveying channel 8 in an image-taking manner;

[0089] The temporary storage bin 5 is used to receive the pile of items output by the conveying channel 8;

[0090] The stora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com