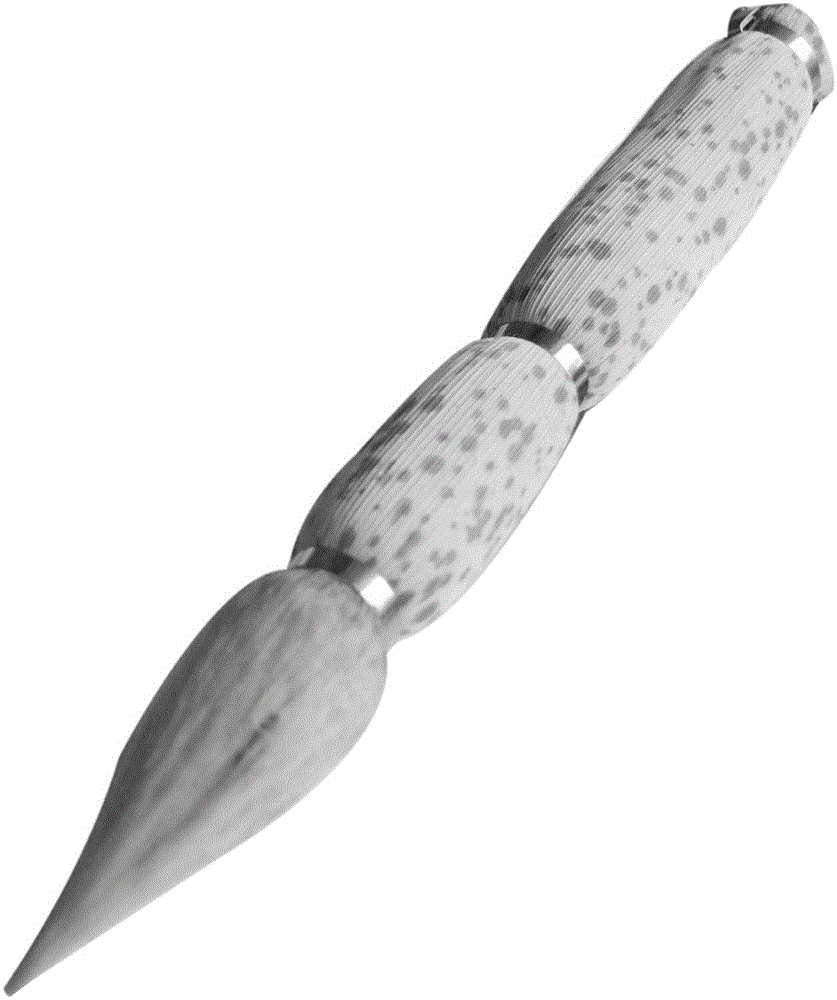

Bamboo shoot clothing brush and production process thereof

A production process and bamboo clothing technology, which is applied to nibs, other ink pens, printing and other directions, can solve the problems of complex production process and high cost of raw materials, and achieve the effects of simple production process, low cost of raw materials and resource saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] 1. Collection and storage of raw materials for bamboo shoots: collect bamboo shoots, dry and store.

[0009] 2. Rinsing: Wash the impurities and dust of the bamboo shoots for processing.

[0010] 3. Process treatment: use the solution to disinfect the bamboo shoot clothing at one time, prevent insects, prevent mildew, soften fibers, develop color, and mercerize.

[0011] 4. Washing: Wash the solution residue with clean water at one time.

[0012] 5. Tear and scrape: Wet-tear the washed bamboo shoots in time, and use the method of tearing and scraping at the same time to tear and scrape the bamboo shoots into hairs, and the softness can be flexibly controlled according to needs.

[0013] 6. Arrangement: Arrange the bamboo shoot fibers that have been torn and scraped into a brush shape.

[0014] 7. Drying: Use sunlight, drying room or dryer to dry completely.

[0015] 8. Binding: Bind the penholders of the bamboo shoots into bamboo joints.

[0016] 9. Inspection: Insp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com