Fused deposition type 3D printer wire exchanging device

A 3D printer and fused deposition technology, which is applied in the field of fused deposition 3D printer filament changing devices, which can solve the problems of broken filaments, vacancies, unsuitable for long periods of time, and unattended printing of large-volume components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

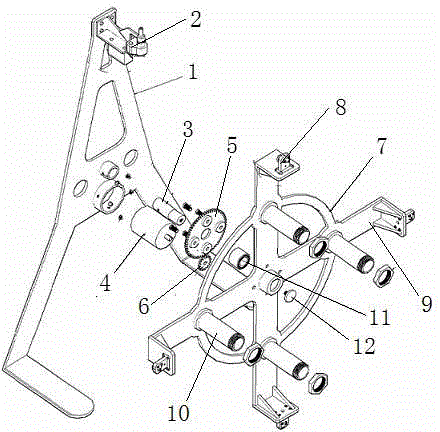

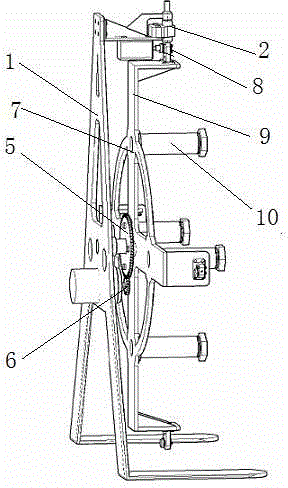

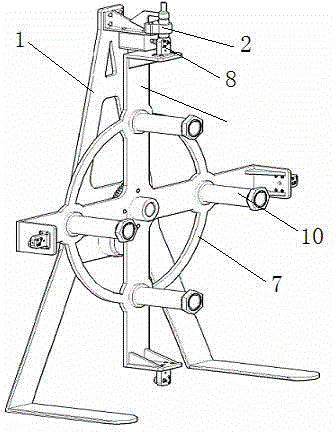

[0023] Such as Figure 1-Figure 11 As shown, the fused deposition type 3D printer wire changing device of the present invention includes a main support 1, a main machine head 2, a main shaft 3, a rotating stepping motor 4, a driven gear 5, a driving gear 6, a rotating frame 7 and a wire guide head 8, A spool 10 is fixed on the circumference of the front part of the swivel frame 7, the main frame head 2 is installed on the top of the main support 1, the main shaft 3 is installed in the shaft hole of the main support 1, and the rotary stepper motor 4 is installed in the motor hole of the main support 1. The driving gear 6 is installed on the main shaft of the rotary stepper motor 4, the driven gear 5 is fixed at the center of the back of the rotary frame 7, the guide wire head 8 is fixed on the support arm 9 of the rotary frame, and the center bearing sleeve hole of the rotary frame 7 There is a bearing 11 in the middle, and the main support 1 passes through the driven gear 5 at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com