Automatic submersible motor copper end ring casting machine

A technology for submersible motors and copper end rings, applied in the direction of casting molds, casting mold components, casting molding equipment, etc., can solve the problems of copper end ring production that cannot be completely solved, does not meet the electromagnetic requirements of the motor squirrel cage, and cannot perfectly meet the process requirements and other problems, to achieve the effect of small strain force, low cost, and not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

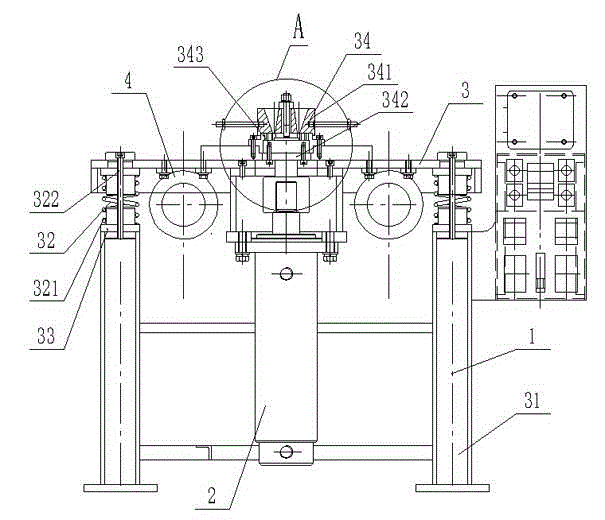

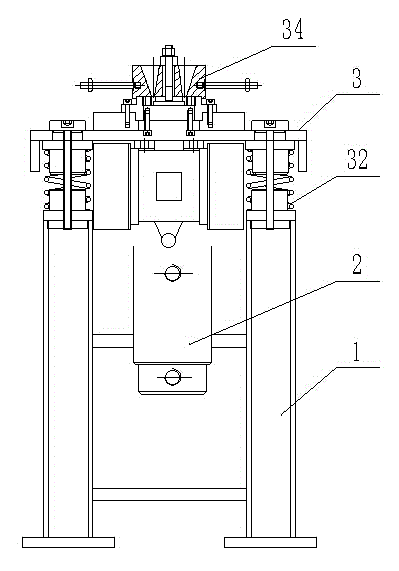

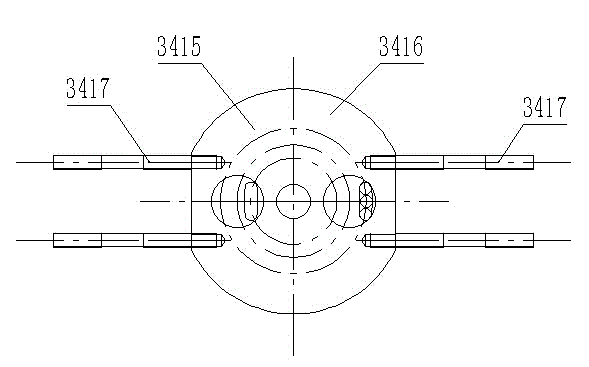

[0026] The present invention will now be described in further detail with reference to the accompanying drawings. The accompanying drawings are simplified schematic diagrams that only illustrate the basic structure of the present invention in a schematic manner, and therefore only show the structures related to the present invention.

[0027] Such as Figure 1~5 As shown, an automatic submersible motor copper end ring casting machine includes a bracket 1 and an oil cylinder 2. The bracket 1 includes a plurality of supporting legs 31 and a workbench 3 arranged at the upper end of the plurality of legs 31. The workbench 3 and multiple legs 31 are connected by elastic devices 32, the workbench 3 can move up and down relative to the legs 31, the workbench 3 is provided with a concave-convex mold 34, the concave mold 341 of the concave-convex mold 34 is movably connected by bolts On the workbench 3, the cylinder body of the oil cylinder 2 is fixedly arranged on the support 1, the pist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com