Producing method of hot-rolled alloy plate for automobile body

A technology for automobile bodies and magnesium alloys is applied in the field of preparation of hot-rolled magnesium alloy sheets for automobile bodies, which can solve problems such as differences in repair processes, and achieve the effects of reducing production costs, improving performance, and simplifying processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation method for a hot-rolled magnesium alloy plate (dispersed quasicrystalline phase strengthened MB8 magnesium alloy strip) for automobile body, comprising the following steps:

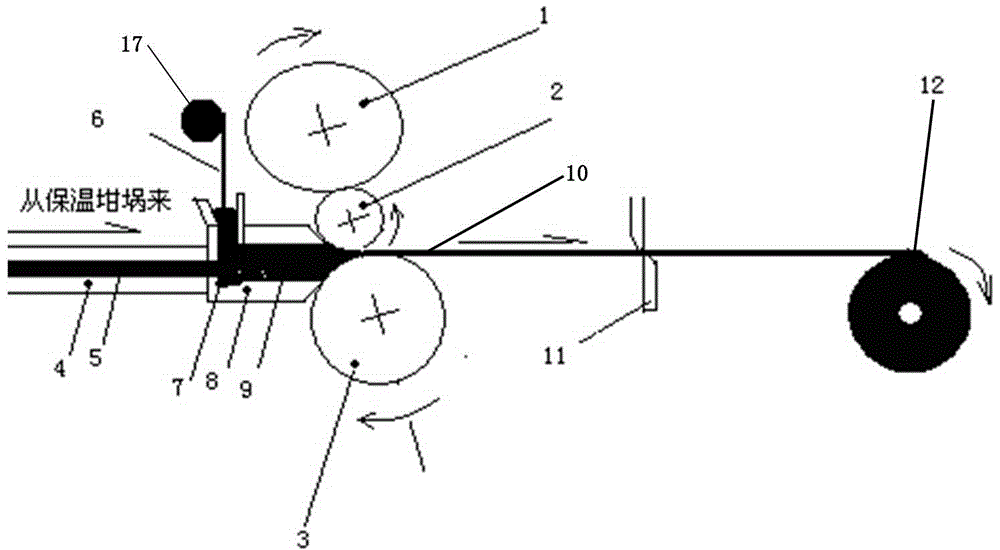

[0028] (1) When MB8 is used as the mother magnesium alloy, when the casting and rolling machine is working, such as figure 1 As shown, the treated clean magnesium alloy liquid 5 is sent to the liquid pool of the front box 7 of the magnesium alloy casting and rolling machine by the heat-sealed pipe 4, and the mother magnesium alloy liquid in the front box 7 is kept at 710°C. The feeder 17 evenly inserts the quasicrystalline master alloy thin strip 6 with a preheating temperature of 300°C into the mother magnesium alloy liquid at a ratio of 0.15% of the total metal mass and melts it, and the quasicrystal master alloy particles are evenly dispersed in the mother magnesium alloy In the liquid flow of the liquid, the molten magnesium alloy liquid 9 is formed. The composition of the quasic...

Embodiment 2

[0034] A method for preparing a hot-rolled magnesium alloy sheet (dispersed quasicrystalline phase strengthened AZ31B magnesium alloy sheet) for automobile body, comprising the following steps:

[0035] (1) When using AZ31D as the mother magnesium alloy, when the casting and rolling machine is working, such as figure 1 As shown, the treated clean mother magnesium alloy liquid 5 is sent to the liquid pool of the front box 7 of the magnesium alloy casting and rolling machine by the heat-sealed pipe 4, and the mother magnesium alloy liquid in the front box 7 is kept at 700°C. The feeder 17 evenly inserts the quasicrystalline master alloy thin strip 6 (composition of Mg-3%Zn-7%Y) with a preheating temperature of 250°C into the mother magnesium alloy solution at a ratio of 0.1% of the total metal mass and is After melting, the quasicrystalline master alloy particles are uniformly dispersed in the liquid flow of the mother magnesium alloy liquid to form a molten magnesium alloy liqu...

Embodiment 3

[0041] A method for preparing a hot-rolled magnesium alloy plate (dispersed quasicrystalline phase strengthened ZK60 magnesium alloy plate) for automobile body, comprising the following steps:

[0042] (1) When ZK60 is used as the mother magnesium alloy, when the casting and rolling machine is working, such as figure 1 As shown, the treated clean magnesium alloy liquid 5 is sent to the liquid pool of the front box 7 of the magnesium alloy casting and rolling machine by the heat-sealed pipe 4, and the mother magnesium alloy liquid in the front box 7 is kept at 705°C. The feeder 17 inserts the quasicrystalline master alloy thin strip 6 (composition of Mg-3%Zn-7%Y) with a preheating temperature of 350°C (composition of Mg-3%Zn-7%Y) into the mother magnesium alloy solution at a ratio of 0.2% of the total metal mass and is After melting, the quasicrystalline master alloy particles are uniformly dispersed in the liquid flow of the mother magnesium alloy liquid to form a molten magne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com