Composite molecular sieve catalyst for preparing aromatics by use of methanol

A composite molecular sieve and catalyst technology, which can be used in molecular sieve catalysts, physical/chemical process catalysts, hydrocarbon production from oxygen-containing organic compounds, etc., and can solve the problems of low BTX yield and low BTX selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

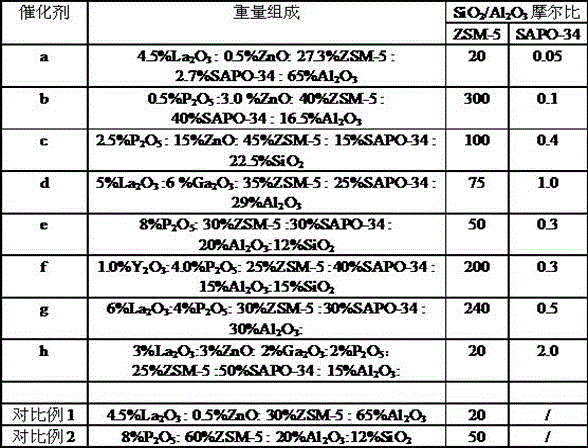

[0018] Weigh 40.4g of hydrogen-form ZSM-5 and 4g of SAPO-34 molecular sieve, and 96.3g of pseudo-boehmite and 5.2g of scallop powder are wet-kneaded and molded with dilute nitric acid with a concentration of 1% by weight. The molded carrier is dried at 100-120°C for 6-24 hours, and calcined at 500-650°C for 1-12 hours. Take 40g of calcined carrier, impregnate 28.3g of aqueous solution containing 9.56g of lanthanum nitrate and 1.47g of zinc nitrate in equal volume, age at room temperature for 6~24 hours, then dry at 100~120°C for 6~24h, and then dry at 500~650°C The catalyst a was obtained by lower roasting for 1-12 hours. The composition of the catalyst is listed in Table 1.

[0019]

Embodiment 2~8

[0021] Catalysts b to k were prepared according to the method given in Example 1, and the composition of the catalysts is listed in Table 1.

[0022]

Embodiment 9~12

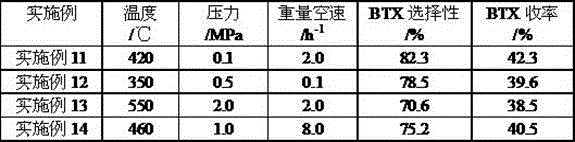

[0036] Embodiments 9-12 are the reaction results obtained by changing the process conditions for the use of catalyst b, and their relevant parameters are listed in Table 3.

[0037] table 3

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com