Cracking catalyst containing metallic oxide modified beta zeolite

A catalyst, beta zeolite technology, applied in physical/chemical process catalysts, catalytic cracking, molecular sieve catalysts, etc., can solve problems such as low liquid yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

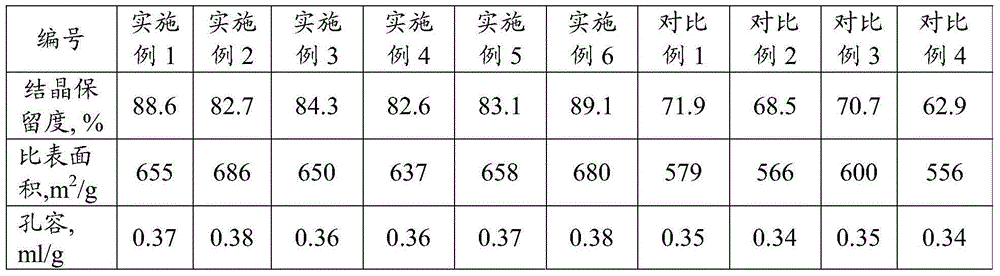

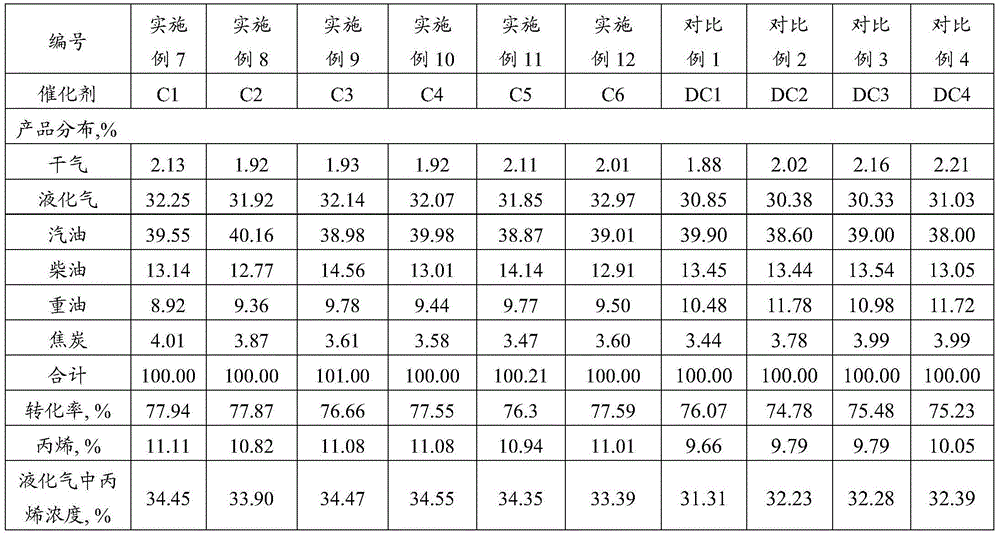

Examples

Embodiment 1

[0033] Take 200g sodium type β zeolite (produced by Sinopec Catalyst Qilu Branch, SiO 2 / Al 2 o 3 =25 (molar ratio), dry basis accounted for 75% by weight), mixed with 3000g deionized water and 45g ammonium chloride for beating, stirred at 80°C for 2 hours, then filtered, and repeated the above process 3 times to make the Na in the zeolite 2 The O content is less than 0.2% by weight, roasted at 600°C and 100% steam for 2 hours to obtain ammonium-exchanged zeolite beta, denoted as A-1;

[0034] 52.3g zirconium nitrate Zr (NO 3 ) 4 ·5H 2 O was dissolved in 150g ethanol (analytically pure) to obtain an impregnation solution, and then the above impregnation solution was mixed with ammonium-exchanged β zeolite A-1 evenly, left to stand for 24 hours, dried at 100°C for 24 hours, and then dried in a nitrogen atmosphere at 500°C Lower roasting for 4 hours, denoted as AC-1;

[0035] Add the above roasted β zeolite AC-1 into 2000g of inorganic acid aqueous solution (dilute hydroch...

Embodiment 2

[0038]Take 200g of sodium-type β zeolite (same as above), mix it with 2000g of deionized water and 45g of ammonium chloride, stir at 80°C for 1 hour, then filter, repeat the above process 3 times, and roast at 650°C and 100% steam for 2 Hours, the β zeolite A-2 after ammonium exchange was obtained; Na in zeolite A-2 2 The O content is less than 0.2% by weight, and the water content is 1% by weight;

[0039] Dissolve 18.9g of zirconium isopropoxide in 450g of ethanol, then mix the resulting solution with ammonium-exchanged zeolite A-2 evenly, stir for 24 hours, dry at 100°C for 24 hours, and bake at 550°C in a nitrogen atmosphere for 3 Hour, obtain the beta zeolite AC-2 after roasting;

[0040] Add the above-mentioned roasted β zeolite AC-2 into 1500 g of oxalic acid aqueous solution with an acid concentration of 2.0 mol / L, continue to stir at 90° C. for 1 hour, then filter and wash with deionized water (the amount of washing water is the dry weight of molecular sieve 15 time...

Embodiment 3

[0043] Take 200g of sodium-type β zeolite (same as above), mix it with 2000g of deionized water and 60g of ammonium chloride for slurry, stir at 90°C for 3 hours, then filter, repeat the above process twice, and Na on the zeolite 2 O content is less than 0.2% by weight, roasted at 500°C for 5 hours to obtain ammonium-exchanged β zeolite A-3;

[0044] 10.5g zirconium nitrate Zr(NO 3 ) 4 ·5H 2 O was dissolved in 200g of ethanol, and then the above solution was mixed evenly with the ammonium-exchanged β zeolite, and dried after standing for 12 hours; the dried zeolite was composed of 25.6g of tetrabutyl titanate and 200g of ethanol Mix the impregnating solution, let it stand for 12 hours, then dry it at 100°C for 24 hours, and roast it under nitrogen atmosphere at 600°C for 2 hours to obtain the roasted zeolite beta, which is denoted as AC-3;

[0045] Add the roasted beta zeolite AC-3 to 1000 g of hydrochloric acid aqueous solution with an acid concentration of 0.5 mol / L, stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com