Fixed fluidized bed reactor and using method thereof

A fixed fluidized bed and reactor technology, applied in the direction of chemical instruments and methods, chemical/physical processes, etc., can solve problems such as inapplicability, achieve the effects of inhibiting coking and carburizing, reducing impact, and avoiding negative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

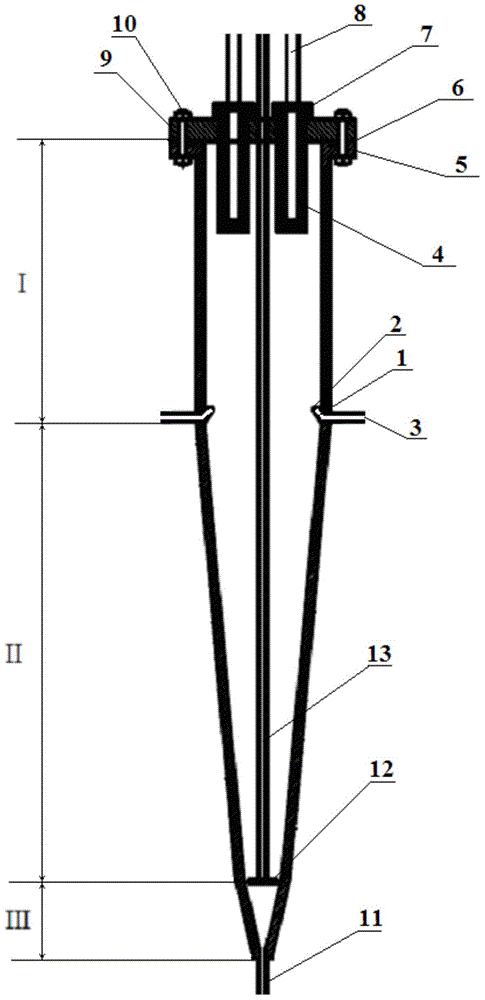

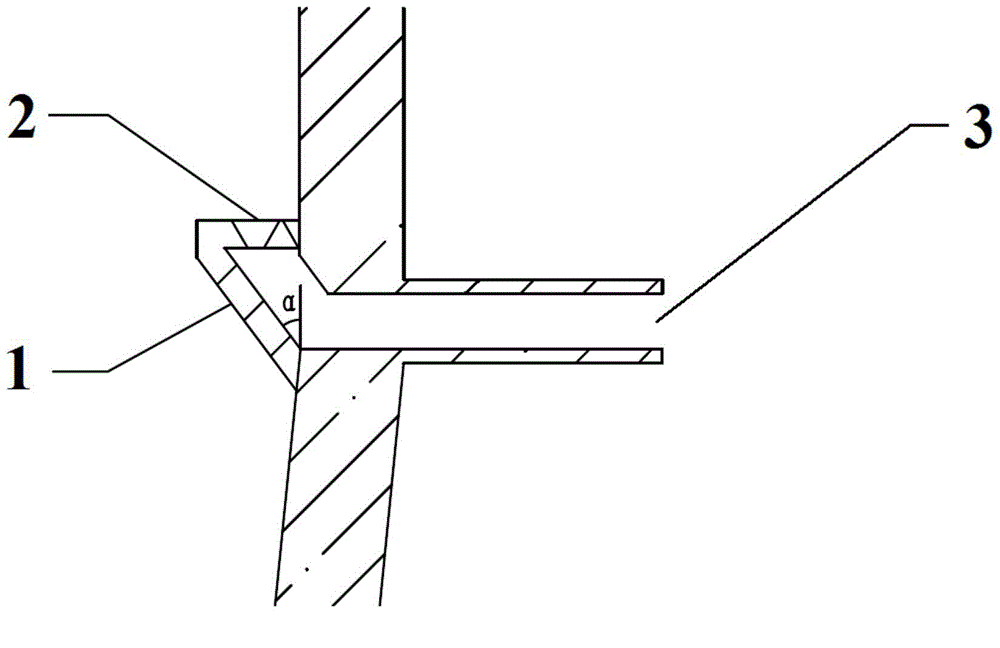

[0077] In the fixed fluidized bed reactor, the relevant dimensions of the coking inhibitor injection part at the bottom of the settling section I include: the angle α between the truncated cone baffle 1 and the wall of the settling section is 35°; the height of the truncated cone baffle It is 7% of the total height of the settling section; the ratio of the inner diameter to the outer diameter of the annular filter plate 2 is 0.8; the number of coking inhibitor injection ports is 2; the material of the annular filter plate is 00Cr17Ni14Mo2.

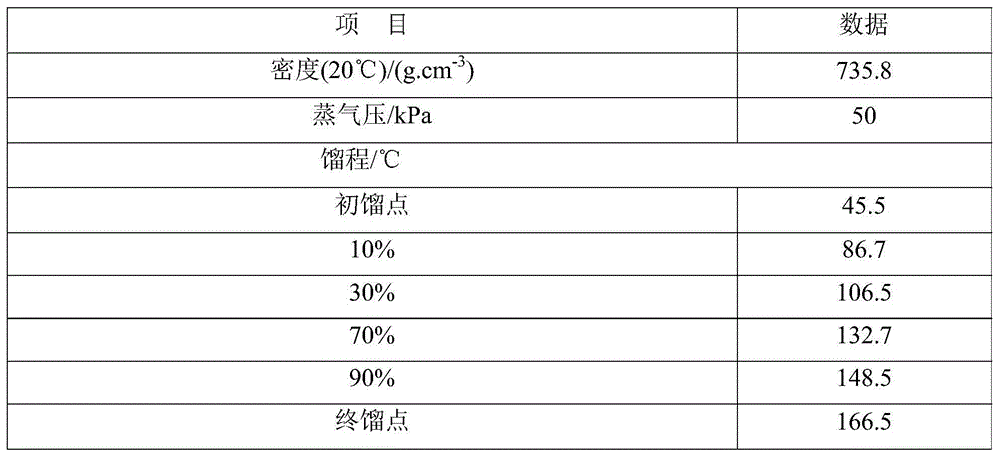

[0078] The carrier gas is steam, and the coking inhibitor is composed of carbon disulfide, ethanedithiol and dimethyl sulfide, and the mass ratio is 2:1:1; 1) The weight ratio is 2×10 -3 , the weight ratio of coking inhibitor to carrier gas is 3×10 -6 Catalyst adopts catalytic cracking catalyst, trade mark is CEP-1, and the character of catalyst is as shown in table 2, and operating conditions is as shown in table 3.

[0079] After the s...

Embodiment 2

[0081] In the fixed fluidized bed reactor, the relevant dimensions of the coking inhibitor injection part at the bottom of the settling section I include: the angle α between the truncated cone baffle 1 and the wall of the settling section is 35°; the height of the truncated cone baffle It is 15% of the total height of the settling section; the ratio of the inner diameter to the outer diameter of the annular filter plate 2 is 0.7; the number of coking inhibitor injection ports is 4; the material of the annular filter plate is 00Cr17Ni14Mo2.

[0082] With water vapor as the carrier gas, the coking inhibitor is composed of carbon disulfide, ethanedithiol and dimethyl sulfide in a mass ratio of 2:1:1; The weight ratio of coking inhibitor injection amount to hydrocarbon feedstock (straight-run naphtha, see Table 1 for properties) is 4×10 -3 ; The weight ratio of coking inhibitor to carrier gas is 3×10 -6 Catalyst adopts catalytic cracking catalyst, trade mark is CEP-1, and the ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com