Reverse osmosis membrane as well as preparation method and application thereof

A technology of reverse osmosis membrane and support layer, used in reverse osmosis, semi-permeable membrane separation, chemical instruments and methods, etc., can solve problems such as salt rejection and poor water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

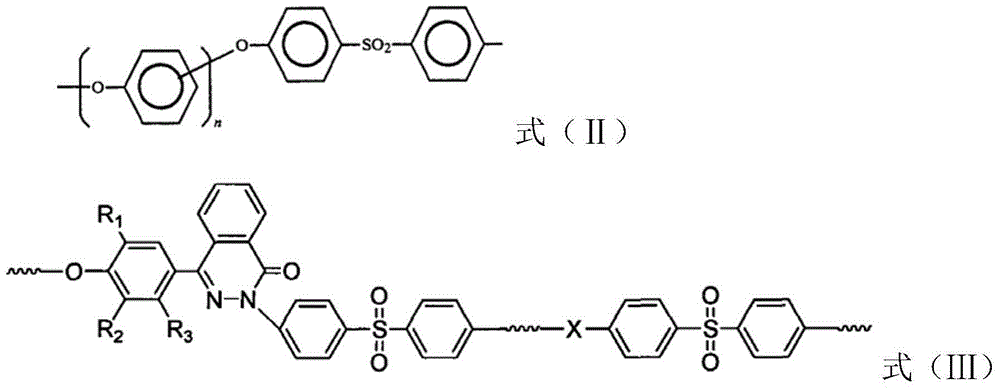

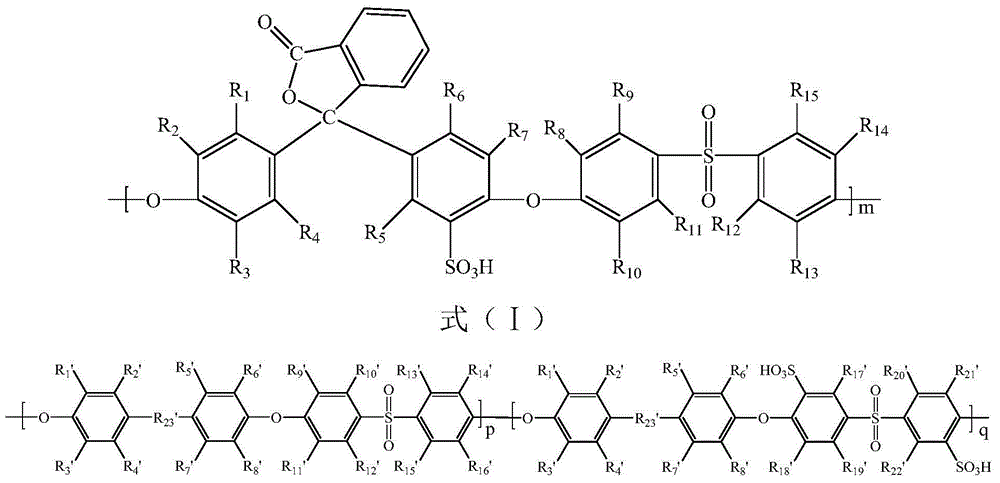

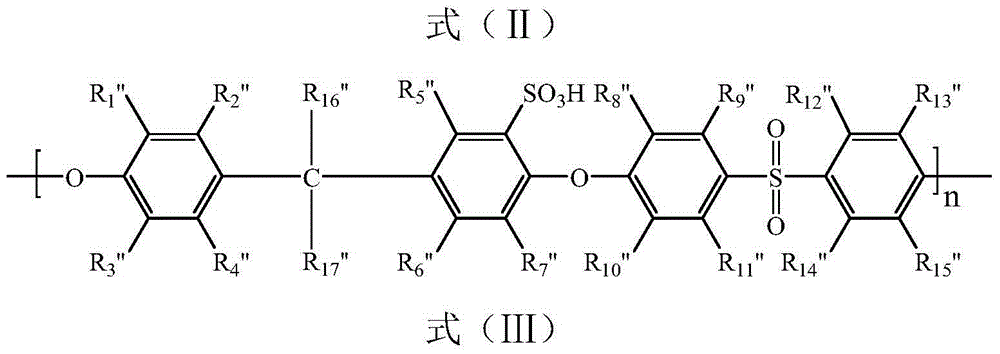

[0042] The preparation method of the reverse osmosis membrane provided by the present invention includes casting polyhedral oligomeric silsesquioxane, a sulfonated polyaryl ether sulfone with a structure shown in any one of formula (I) to formula (III), and a solvent. The membrane liquid is coated on the support layer to form a nascent membrane, and the solvent in the nascent membrane is removed to obtain a reverse osmosis membrane of the support layer and the separation layer on the surface of the support layer;

[0043]

[0044] Among them, in formula (Ⅰ), R 1 -R 15 Same or different, and each independently is H or C 1 -C 5 The alkyl group, m≥2;

[0045] In formula (Ⅱ), R 1 '-R 22 'Same or different, and each independently is hydrogen or C 1 -C 5 The alkyl group, R 23 'Is a chemical bond or C 1 -C 5 The alkylene group, p: q=0-10:1;

[0046] In formula (Ⅲ), R 1 ''-R 17 ''Same or different, and each independently is hydrogen or C 1 -C 5 The alkyl group, n≥2.

[0047] The present inven...

Embodiment 1

[0072] This example is used to illustrate the reverse osmosis membrane provided by the present invention and its preparation method.

[0073] 0.01g of monoaminopropyl heptaisobutyl silsesquioxane with the structure represented by formula (Ⅷ) was added to 100g of a mixed solvent (formic acid, ethylenedioxide) composed of formic acid, ethylene glycol monomethyl ether and deionized water The weight ratio of alcohol monomethyl ether and deionized water is 70:25:5, the same below), the uniform dilute solution is made after ultrasonic dispersion. Then add 1.0g of dried C-SPAES (purchased from Tianjin Yanjin Technology Co., Ltd., with the structure shown in formula (IV), R 1 -R 15 Is H, m is 60, and ion exchange capacity is 1.49mmol / g), after stirring and dissolving, a casting solution is prepared. Fix the bisphenol A polysulfone ultrafiltration membrane (purchased from Dow Chemical, the thickness is 125 microns, the same below) on the glass plate, and evenly brush the prepared casting ...

Embodiment 2

[0076] This example is used to illustrate the reverse osmosis membrane provided by the present invention and its preparation method.

[0077] Add 0.02g monoaminopropyl heptaisobutyl silsesquioxane with the structure represented by formula (VIII) into 100g mixed solvent composed of formic acid, ethylene glycol monomethyl ether and deionized water, after ultrasonic dispersion Make a homogeneous dilute solution. Then add 1.0g of dried C-SPAES (purchased from Tianjin Yanjin Technology Co., Ltd., with the structure shown in formula (IV), R 1 -R 15 It is H, m is 80, and the ion exchange capacity is 1.37mmol / g). After stirring and dissolving, a casting solution is prepared. Fix the bisphenol A polysulfone ultrafiltration membrane on the glass plate, and evenly brush the prepared casting solution on the surface of the ultrafiltration membrane, and then heat it at 70°C for 30 minutes to obtain the support layer and the The reverse osmosis membrane M2 of the separation layer on the surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com