Tooth selection and positioning mechanism of metal zipper punching machine

A metal zipper and positioning mechanism technology, applied in the direction of sliding fastener components, applications, fasteners, etc., can solve the problem of the deviation of the number of microphone teeth, and achieve the effect of avoiding the number deviation, equalizing the number of microphone teeth, and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

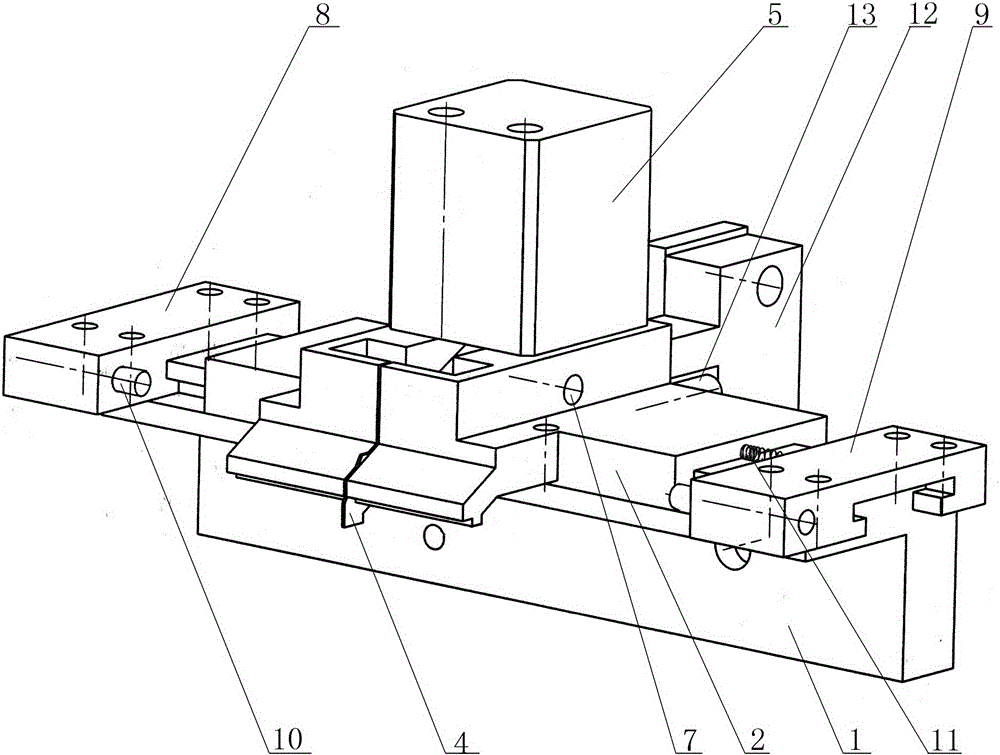

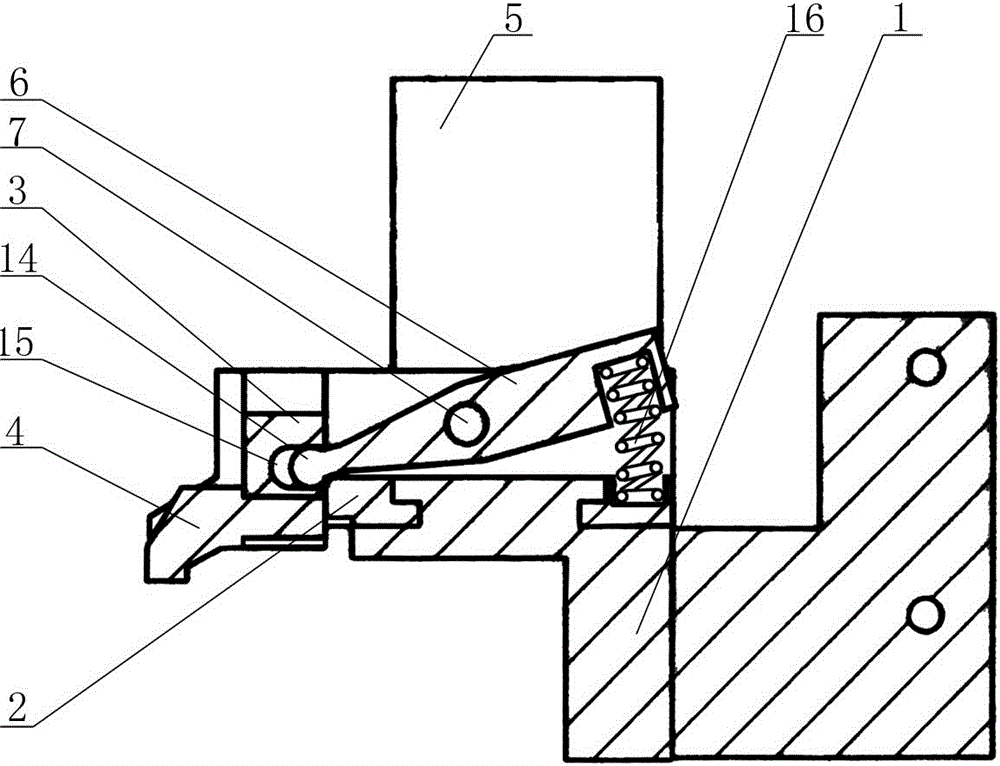

[0014] The present invention will be further described below in conjunction with accompanying drawing:

[0015] Depend on figure 1 combine figure 2 As shown, the tooth selection and positioning mechanism of the metal zipper punching machine includes a track 1, a ram 2 that can slide is provided above the track 1, and a slider that can slide up and down is provided on the side of the ram 2 along the direction perpendicular to the track 1 3. The positioning blade 4 is fixed on the slider 3, the thickness of the positioning blade 4 is smaller than the pitch of the teeth, the cylinder 5 and the swing arm 6 are installed on the ram 2, the swing arm 6 is hinged with the ram 2, and the swing arm 6 One end can move the slider 3, the top of the other end of the swing arm 6 corresponds to the piston rod of the cylinder 5 and the bottom is provided with a spring 16; the two ends of the track 1 are respectively fixed with a left positioning block 8 and a right positioning block 9, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com