Automatic numerically-controlled sliced noodle production device

A production equipment and noodle-cutting technology, which is applied in the field of automatic CNC knife-cut noodle production equipment, can solve the problems of high work intensity, high time and temperature requirements, and high technical requirements for cutting noodles, so as to save power consumption and realize automatic production , beautiful appearance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

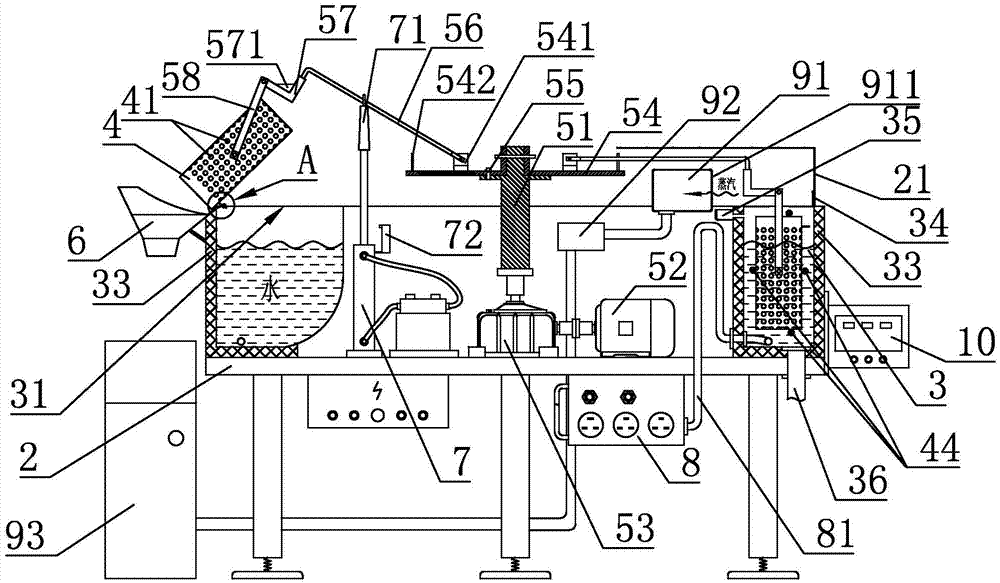

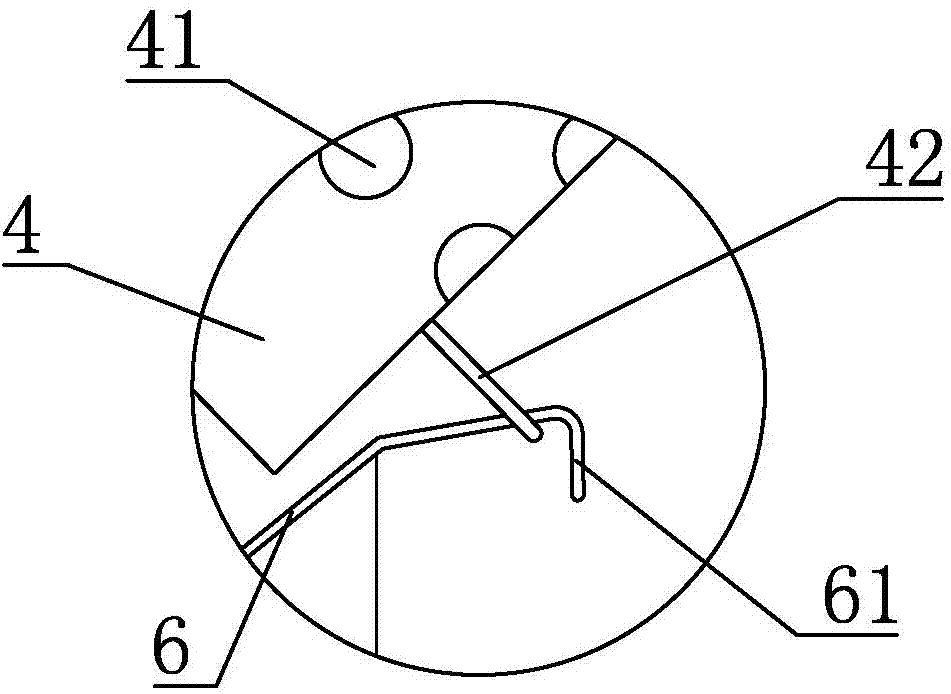

[0019]As shown in the figure, an automatic CNC knife-cut noodle production equipment includes an automatic noodle slicer 1 and an automatic noodle cooking device. The automatic noodle cooking device includes a ring frame 2, an annular water tank 3 is arranged on the ring frame 2, and the inside of the ring water tank 3, etc. 20 noodle baskets 4 are evenly spaced, and filter holes 41 are provided on the sides and bottom of the noodle baskets 4, and the noodle basket rotation driving assembly is fixed on the ring frame 2 to drive the noodle baskets 4 to rotate horizontally in the annular water tank 3 , the basket rotating drive assembly includes a rotating shaft 51, a motor 52 and a gearbox 53 fixedly arranged on the ring frame 2, the output shaft of the motor 52 is connected with the gearbox 53, and the output shaft of the gearbox 53 is fixed to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com