Automatic chicken coop and automatic feeding device and automatic waste feed cleaning device thereof

A technology for automatic feeding and raising of chicken cages, applied in the field of chicken cages, can solve the problems of low production efficiency, high labor intensity, mixed living of humans and poultry, etc., and achieve the effects of reducing labor intensity, liberating productivity and saving labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

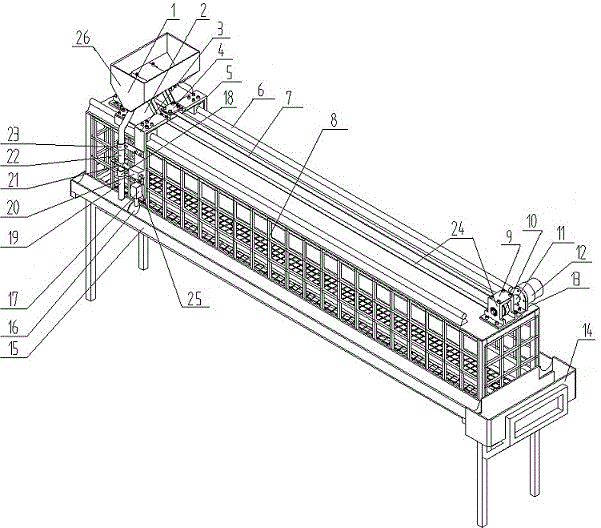

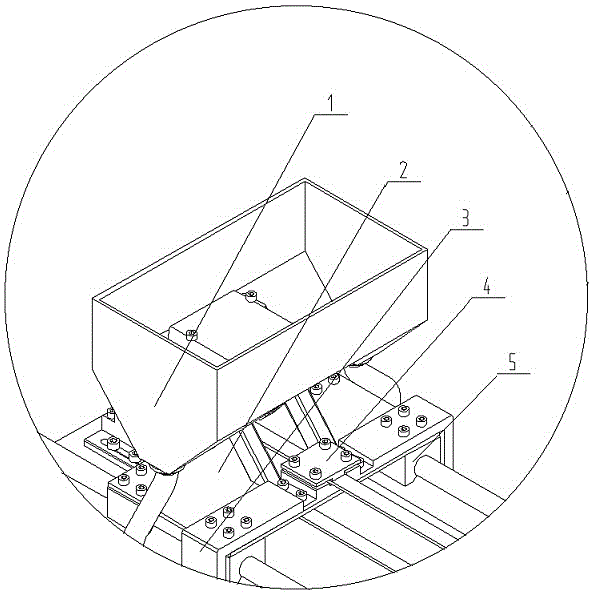

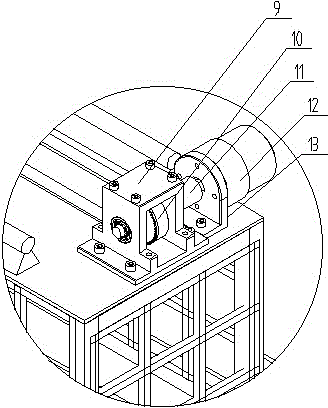

[0036] like figure 1 , figure 2 , image 3 and Figure 4 As shown, the present embodiment is installed on the existing mesh type ventilated chicken cage frame 8, the chicken cage frame 8 can be built by 30 * 30 aluminum profiles, and the chicken cage frame 8 six sides can be made of a diameter of 1mm pitch appropriate steel wire mesh. The left and right sides of the lower part of the food material box 1 are made into a funnel shape, and the bottom of the funnel is connected with the upper food feeding pipe 22 respectively. The guide sliders 5 are fixedly connected, that is, every two guide sliders 5 and a guide slide rail 6 form a guide rail, forming two left and right guide rails. When the guide slide 6 is implemented, the bearing steel cylindrical linear guide with a supporting optical axis and an aluminum bracket can be selected for use, and when the guide slide 5 is implemented, the box-type linear slide block with an opening matched with the slide rail diameter can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com