Optical-mechanical structure based on infrared area array detector scanning imaging

A detector, opto-mechanical technology used in the field of infrared detection systems to solve problems such as blurring and smearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

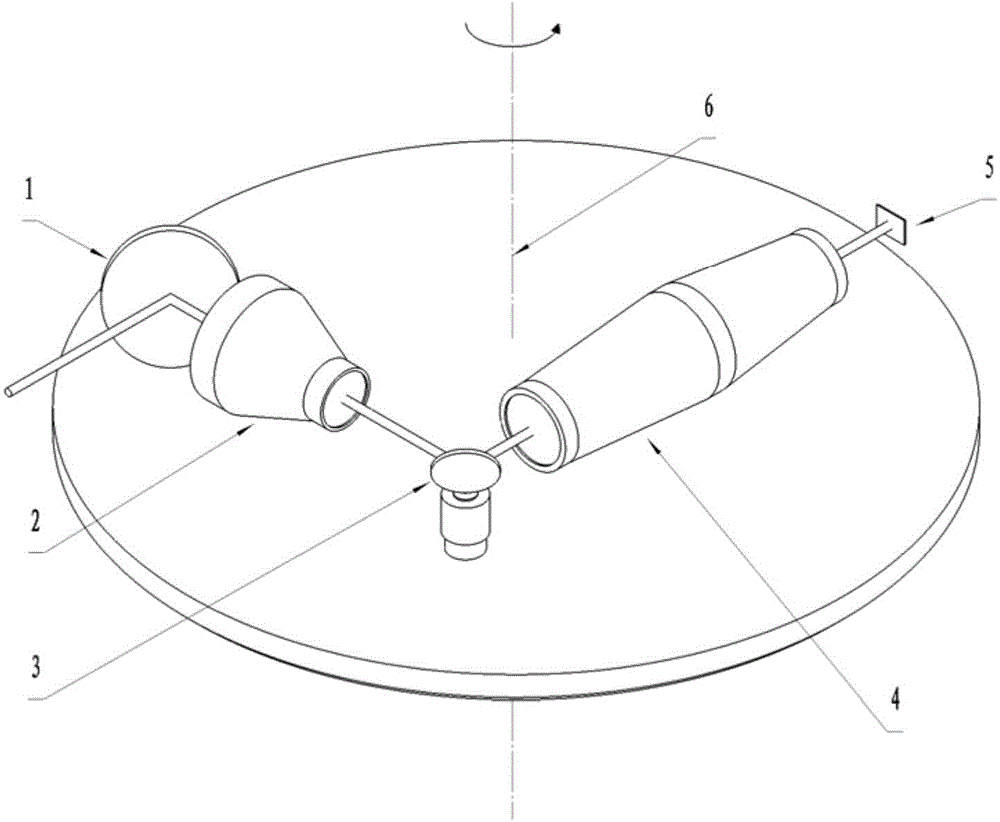

[0012] According to attached figure 1 The diagram of the marked:

[0013] The pitch pointing mirror 1 is a plane mirror with adjustable pitch angle, and its function is to adjust the pitch angle value of the imaging field of view. The value of the pitch angle is generally adjusted before the system works, and the pitch pointing mirror 1 remains fixed after the integration of the detector starts.

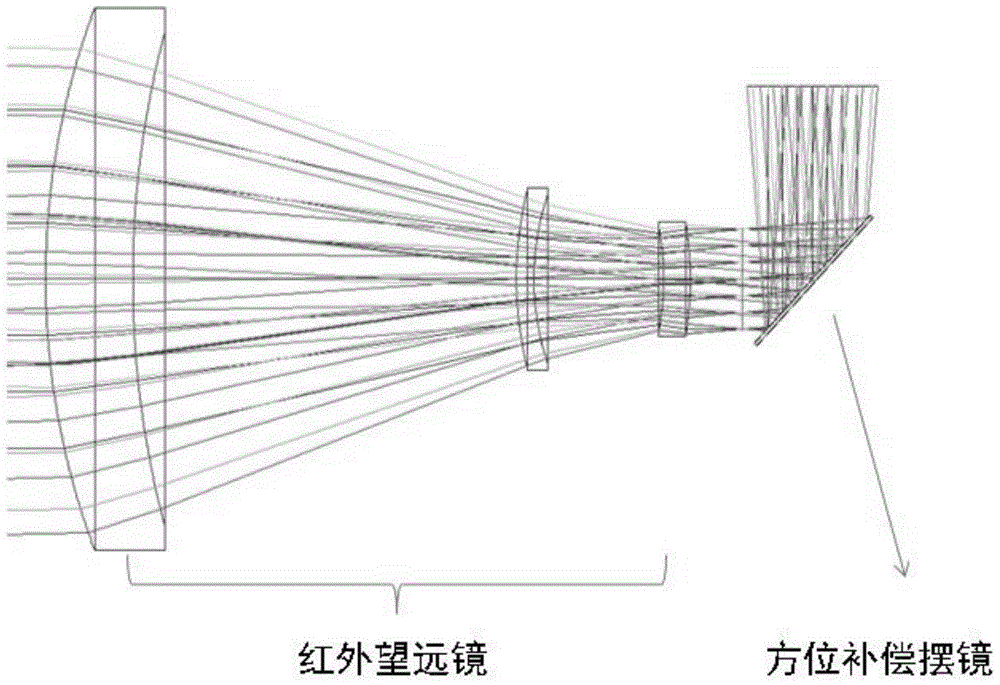

[0014] The infrared telescopic lens 2 is an infrared optical system with no optical power, and its function is to compress the infinite parallel light beam at the entrance pupil to the exit pupil, and exit as parallel light. Its angular magnification is γ. It can be obtained from the characteristics of the telescopic optical system that the ratio of the entrance pupil size to the exit pupil size is also γ. The larger the γ, the smaller the size of the azimuth compensation oscillating mirror 3 in the subsequent optical path, which is beneficial for the motor to control the oscilla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com