Microbial fuel cell by taking conducting film aerating bio-film reactor as cathode

A technology of aerated organisms and membrane reactors, applied in the field of water treatment, can solve the problems of complex management and high operating costs, and achieve the effects of convenient operation and management, fast film formation, and efficient removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

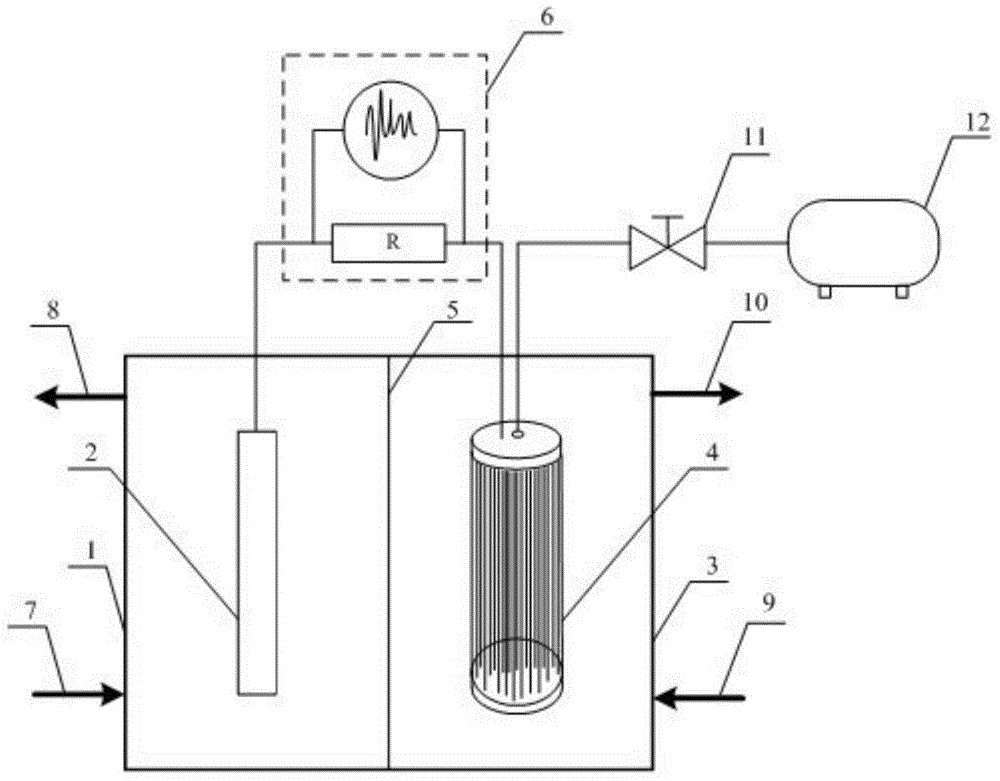

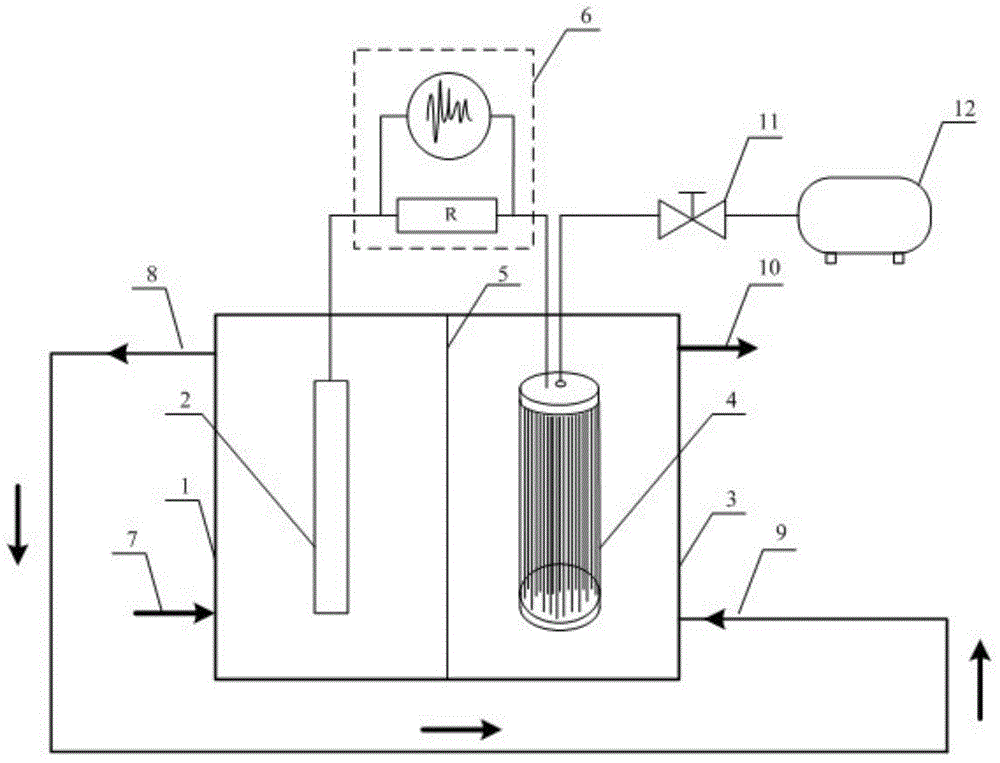

[0020] Embodiment 1: a kind of microbial fuel cell with conductive film aerated biofilm reactor as negative electrode, comprises reactor, is provided with separation film 5 in the middle part of reactor and makes reactor be divided into anode chamber 1 and cathode chamber 3, in An anode 2 is arranged inside the anode chamber, and a cathode 4 is arranged inside the cathode chamber. Water outlets 8 and 10 are respectively provided on the upper part of the cathode chamber and the wall of the cathode chamber. The cathode is a conductive film aerated biofilm reactor, and the conductive film aerated biofilm reactor is connected with the air flow meter 11 and the air pump 12 in turn through the pipeline. . (See figure 1 )

[0021] The separation membrane of this embodiment is a proton exchange membrane; the anode is selected from carbon felt; the aeration membrane module of the conductive membrane aerated biofilm reactor is a hollow fiber membrane module with bubble-free oxygen sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com