Pin positioning device and pin positioning whole device including same

A technology for positioning devices and pins, which is applied in the fields of overall pin positioning devices, positioning devices, and pin positioning devices. The effect of improving and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

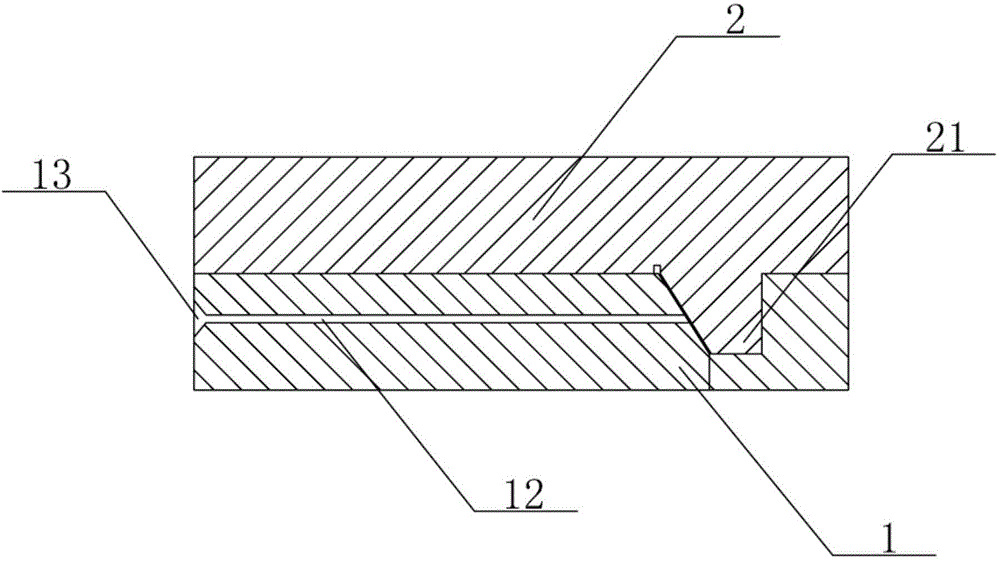

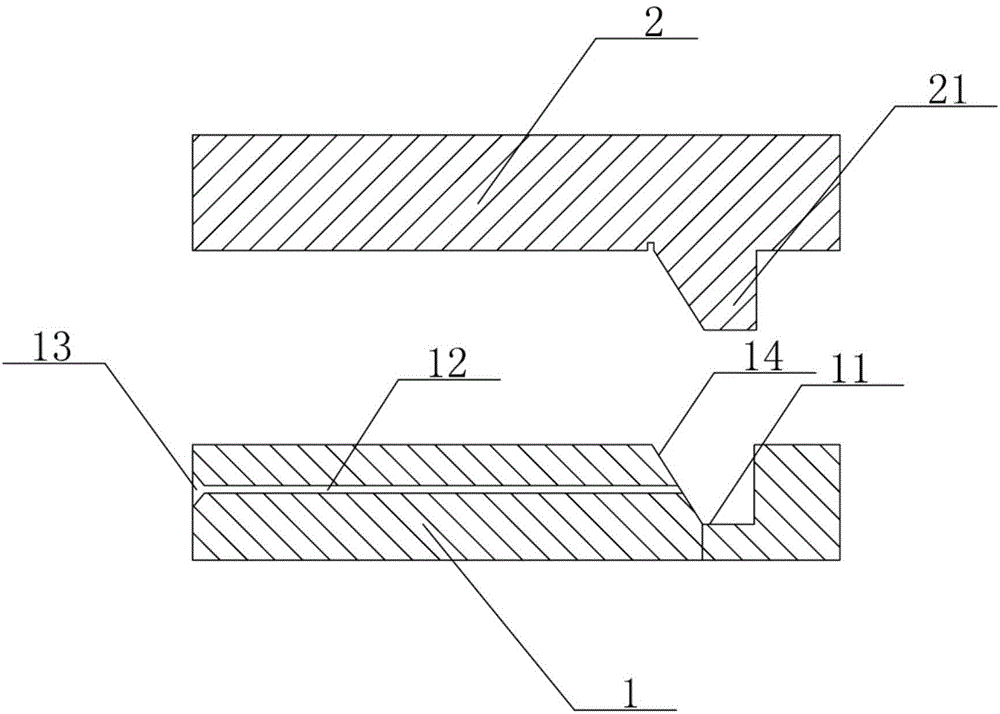

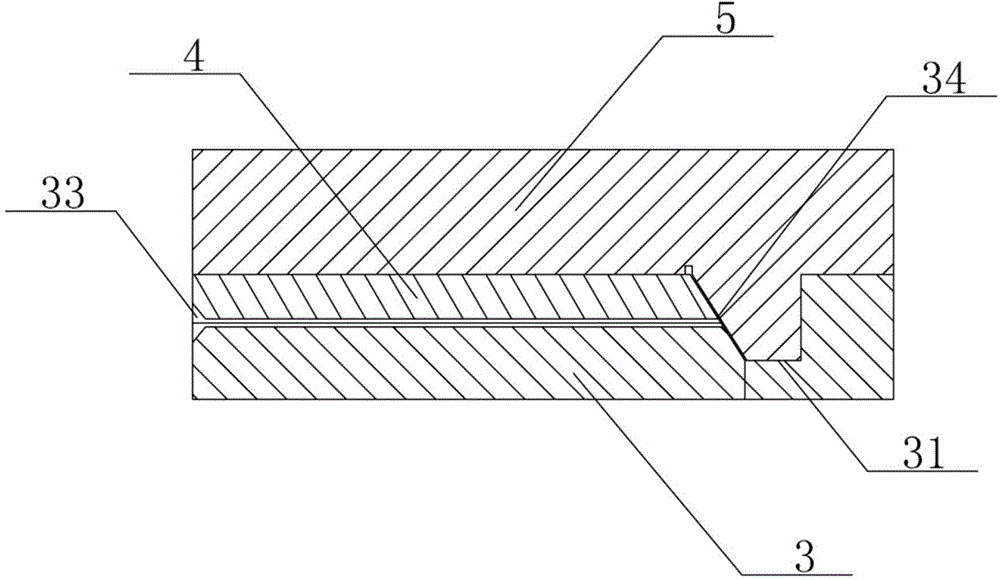

[0038] In order to achieve the purpose of the present invention, as Figure 1-2 As shown, in one embodiment of the pin positioning device of the present invention, it mainly includes a first positioning element 1 and a second positioning element 2, wherein a groove 11 is opened on the first positioning element 1, and the concave The groove 11 is opened from the top of the first positioning element 1 towards the bottom in the figure, and the groove 11 can be set as a large groove, or can be set as a plurality of side-by-side grooves, and the first positioning element 1 also has A through hole 12 is also provided along its length direction, and the through hole 12 extends from one end of the first positioning element 1 into the groove 11, that is, opens between one end of the first positioning element 1 and the groove 11 A channel, if the widt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com