Water-based conductive polymer and graphene dispersion liquid and preparation method thereof

A technology of graphene dispersion liquid and conductive polymer, which is applied in the direction of cable/conductor manufacturing, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., which can solve the complex preparation process, restrict the industrial development of graphene, and low concentration and other problems, to achieve the effect of good repeatability, good conductivity and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0111] Step 1: Preparation of conductive polymer aqueous solution

[0112] At room temperature, polyethylene dioxythiophene doped with polyvinyl sulfonic acid was uniformly mixed in deionized water to obtain an aqueous conductive polymer aqueous solution with a mass percent concentration of 3 wt %;

[0113] Step 2: Ultrasonic peeling preparation mixture

[0114] (A) At room temperature, add graphite to the aqueous conductive polymer aqueous solution prepared in step 1, and mix uniformly to obtain a graphite mixed solution;

[0115] Dosage: 2g of graphite needs 80mL of conductive polymer aqueous solution;

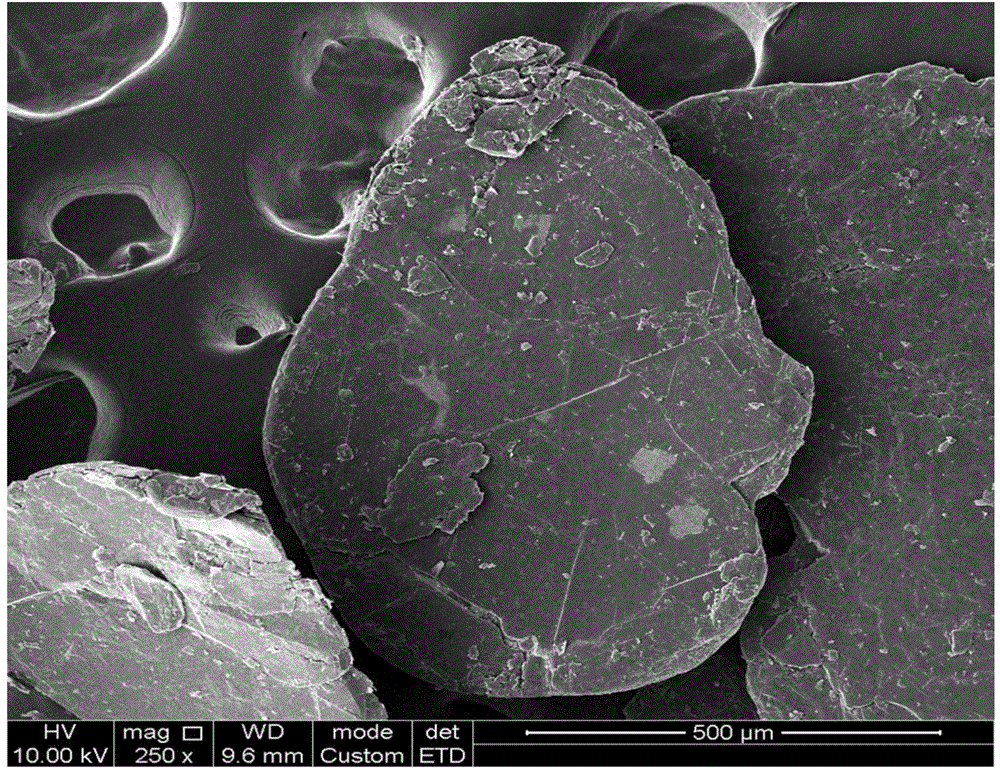

[0116] In the present invention, the scanning electron microscope picture of graphite raw material is as follows figure 1 shown.

[0117] (B) Put the graphite mixed solution in an ultrasonic generator, and after ultrasonic dispersion at an ultrasonic frequency of 60KHz for 36 hours, an aqueous conductive polymer-graphene mixed solution is obtained.

[0118] Step 3: Centr...

Embodiment 2

[0128] Step 1: Preparation of conductive polymer aqueous solution

[0129] At room temperature, polyacrylic acid-doped polyaniline was uniformly mixed in deionized water to obtain an aqueous conductive polymer aqueous solution with a mass percent concentration of 5 wt %;

[0130] Step 2: Ultrasonic peeling preparation mixture

[0131] (A) At room temperature, add graphite to the aqueous conductive polymer aqueous solution prepared in step 1, and mix uniformly to obtain a graphite mixed solution;

[0132] Dosage: 2g of graphite needs 50mL of conductive polymer aqueous solution;

[0133] (B) Put the graphite mixed solution in an ultrasonic generator, and after ultrasonic dispersion at an ultrasonic frequency of 80KHz for 48 hours, an aqueous conductive polymer-graphene mixed solution is obtained.

[0134] Step 3: Centrifugal separation to prepare dispersion liquid

[0135] Place the aqueous conductive polymer-graphene mixture prepared in step 2 in a centrifuge, and centrifuge...

Embodiment 3

[0138] Step 1: Preparation of conductive polymer aqueous solution

[0139] At room temperature, the aniline / N-propanesulfonic acid aniline copolymer is uniformly mixed in deionized water to obtain a water-based conductive polymer aqueous solution with a mass percent concentration of 1 wt %;

[0140] Step 2: Ultrasonic peeling preparation mixture

[0141] (A) At room temperature, add graphite to the aqueous conductive polymer aqueous solution prepared in step 1, and mix uniformly to obtain a graphite mixed solution;

[0142] Dosage: 2g of graphite needs 100mL of conductive polymer aqueous solution;

[0143] (B) Put the graphite mixed solution in an ultrasonic generator, and after ultrasonic dispersion at an ultrasonic frequency of 20KHz for 36 hours, an aqueous conductive polymer-graphene mixed solution is obtained.

[0144] Step 3: Centrifugal separation to prepare dispersion liquid

[0145] Place the aqueous conductive polymer-graphene mixture prepared in step 2 in a centr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com