Black photosensitive resin composition and application of black photosensitive resin composition

A technology of photosensitive resin and composition, which is applied in the field of materials and can solve the problems that the cover film technology cannot meet the requirements of the market.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

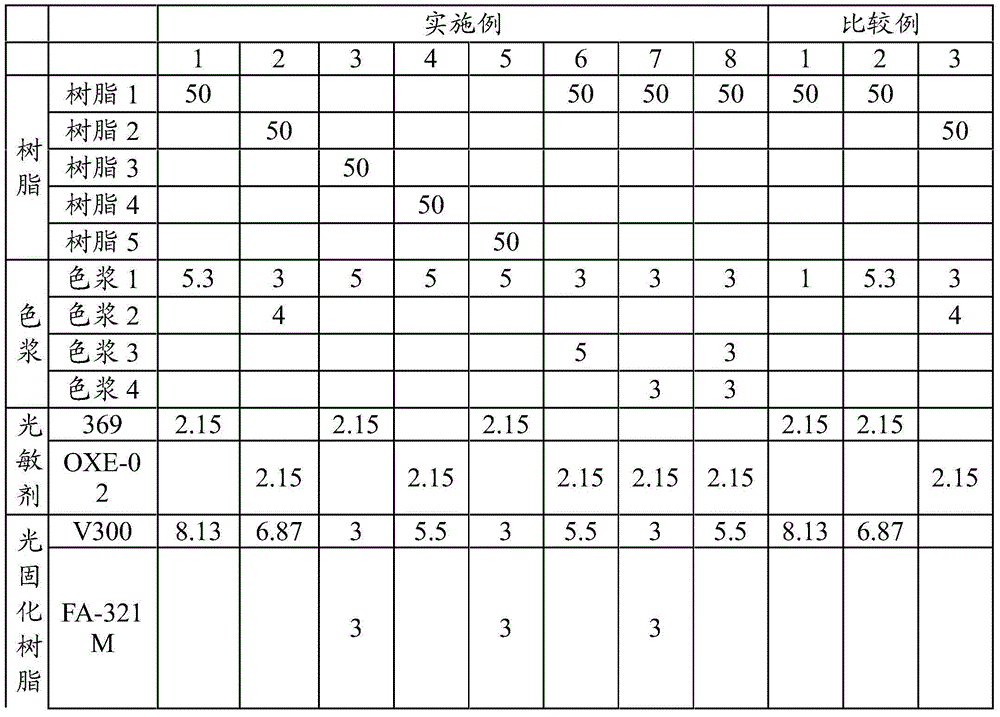

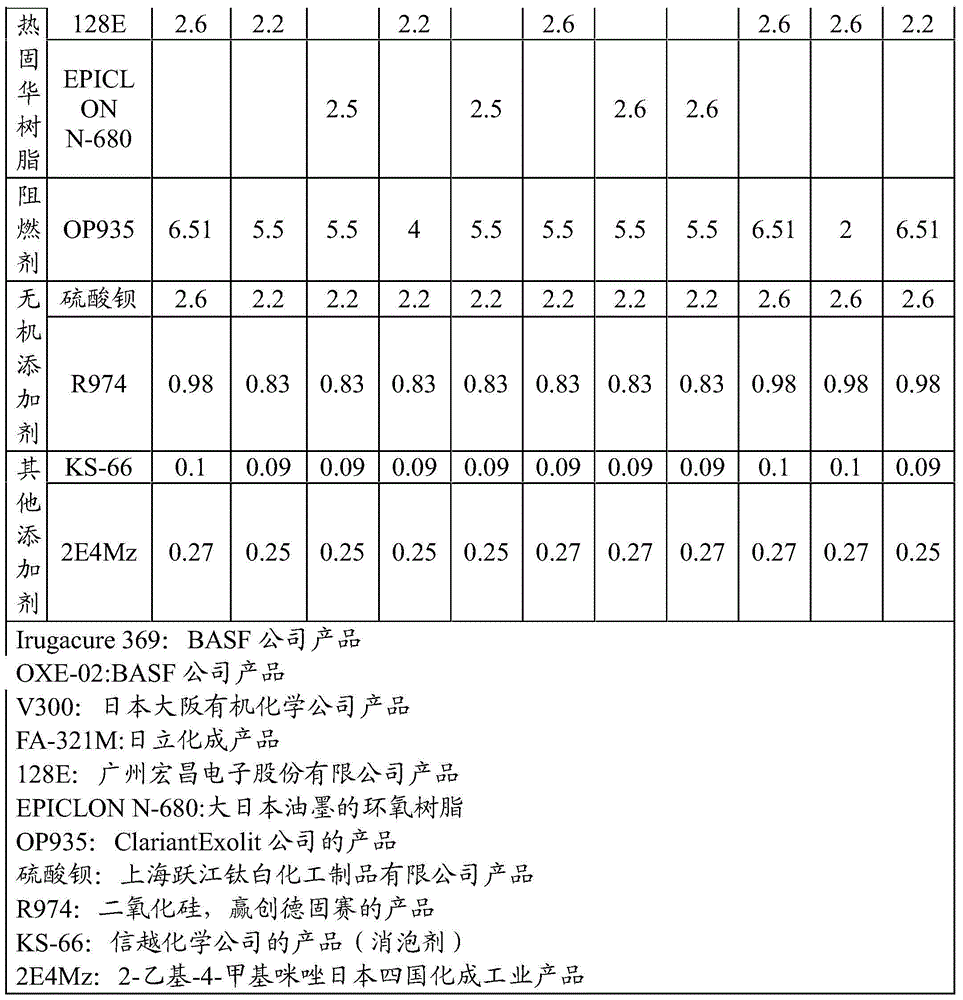

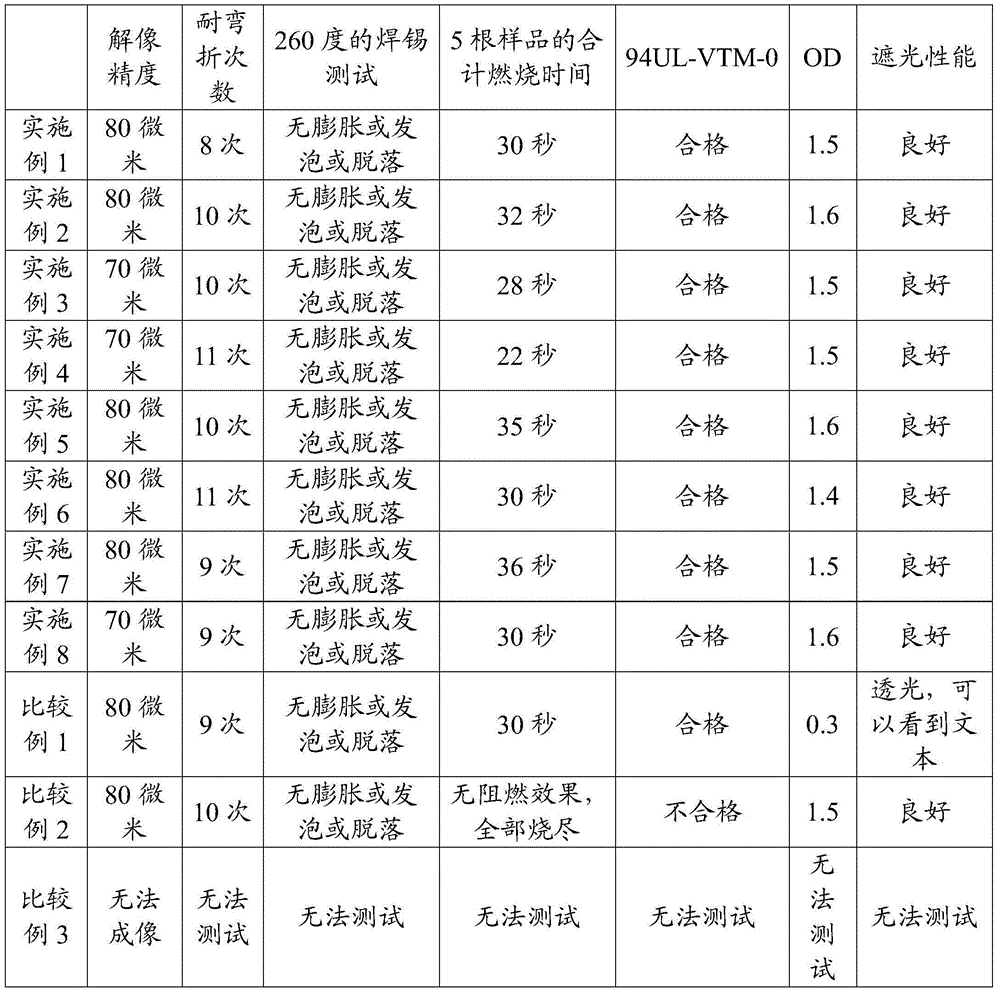

Method used

Image

Examples

Synthetic example 1

[0071] Synthesis example 1: Synthesis of acid-modified epoxy resin-(meth)acrylic resin

[0072] In a four-necked flask equipped with a stirrer, a reflux condenser, and a nitrogen tube, feed nitrogen, and add 207.1 grams of epoxy resin (YDCN-704, the epoxy equivalent of which is 207.1) (to Japan Toto Chemical), diethylene di 186 grams of alcohol ethyl ether acetate, 73 grams of acrylic acid, 0.8 grams of triphenylphosphine, and 0.03 grams of 4-hydroxy-2,2,6,6-tetramethylpiperidine-1-oxyl radical, stirred into a homogeneous solution Afterwards, gradually heated to 120 degrees, after 12 hours, added 66 grams of tetrahydrophthalic anhydride in the reactor, then adjusted the reaction temperature to 100 degrees, stirred for 5 hours, and obtained an acid-modified epoxy resin with a solid content of 65wt%. - Acrylic resin, called black photoresist 1

Synthetic example 2

[0073] Synthesis Example 2: Synthesis of Polyurethane Resin

[0074] In a four-necked flask equipped with a stirrer, a reflux condenser, and a nitrogen tube, feed nitrogen, add 25.00 grams (0.1 moles) of xylylmethane 4,4-diisocyanate, and 15 grams of γ-butyrolactone, and stir After uniformity, heat to 90 degrees, then drop into this solution polycarbonate diol (the product of Asahi Kasei Co., Ltd., PCDL T5651) 30 grams (0.03 mole), dimethylolpropionic acid 4.02 grams (0.03 mole) and two Ethylene glycol ethyl ether acetate 25 grams, this solution is heated, and after stirring at 95 degree for 5 hours again, obtains uniform transparent viscous macromolecular liquid. Then add 6.08 grams of glycolic acid (0.08 moles) and 6 grams of diethylene glycol ether acetate in this solution, continue to heat at 90 degrees, stir for 5 hours, so as to obtain the polyurethane oligomer that the end is a hydroxy acid, solid The content is about 55wt%, and this polyurethane compound is called bla...

Synthetic example 3

[0075] Synthesis Example 3: Synthesis of Polyurethane Resin

[0076] In a four-necked flask equipped with a stirrer, a reflux condenser, and a nitrogen tube, feed nitrogen, add 25.00 grams (0.1 moles) of xylylmethane 4,4-diisocyanate, and 15 grams of γ-butyrolactone, and stir After uniformity, heat to 90 degrees, then drop into this solution polycarbonate diol (the product of Asahi Kasei Co., Ltd., PCDL T5651) 30 grams (0.03 mole), dimethylolpropionic acid 4.02 grams (0.03 mole) and two Ethylene glycol ethyl ether acetate 25 grams, this solution is heated, and after 5 hours of stirring at 95 degree of degree again, obtain uniform transparent viscous macromolecule liquid. Then add 3.04 grams of glycolic acid (0.04 moles) and 4.65 grams of hydroxyethyl acrylate (0.04 moles) and 7 grams of solvent diethylene glycol ethyl ether acetate in this solution, continue to heat at 90 degrees, stir for 5 hours, thereby The obtained polyurethane oligomer whose terminal is hydroxy acid and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com