Energy transferring optical cable

An optical cable and cladding technology, applied in the field of energy transmission optical cables, can solve the problems of short service life, reduce the overall strength of the optical cable design, the strength of the end connector, and affect the performance of the components, so as to prolong the service life and achieve long-term stability and reliability. Transmission, ensure long-term stable light guide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

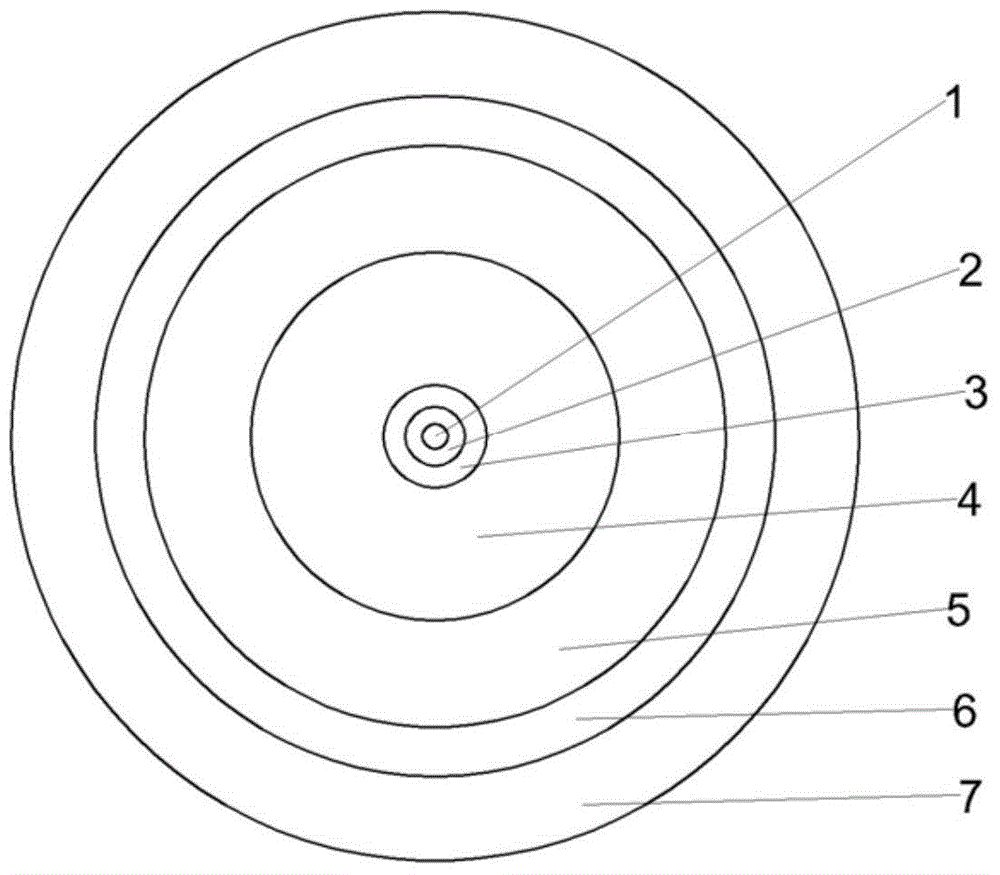

[0036] An energy transmission optical cable, comprising:

[0037] A core layer 1, which is made of quartz glass material, the diameter of the core layer 1 is 0.195mm;

[0038] A cladding layer 2, which covers the core layer 1, the cladding layer is composed of quartz glass material, and the thickness of the cladding layer is 0.012mm;

[0039] A tight cladding 4 covering the cladding 2, the tight cladding 4 is made of ethylene-tetrafluoroethylene copolymer material, and the thickness of the tight cladding 4 is 0.3 mm;

[0040] The outer sheath 7 covers the tight cladding 4, the outer sheath 7 is made of ethylene-tetrafluoroethylene copolymer material, and the thickness of the outer sheath 7 is 0.2 mm.

[0041] The energy transmission optical cable also includes:

[0042] The coating layer 3 is coated on the outer surface of the cladding layer 2, the refractive index of the coating layer 3 is 1.5, and the thickness is 0.05mm.

[0043] In the energy transmission optical cable,...

Embodiment 2

[0053] An energy transmission optical cable, comprising:

[0054] A core layer 1, which is made of quartz glass material, the diameter of the core layer 1 is 0.205mm;

[0055] A cladding layer 2, which covers the core layer 1, the cladding layer 2 is composed of quartz glass material, and the thickness of the cladding layer 2 is 0.016mm;

[0056] A tight cladding 4, which covers the cladding 2, the tight cladding 4 is made of ethylene-tetrafluoroethylene copolymer material, and the thickness of the tight cladding 44 is 0.5mm;

[0057] The outer sheath 7 covers the tight cladding 4, the outer sheath 7 is made of ethylene-tetrafluoroethylene copolymer material, and the thickness of the outer sheath 7 is 0.5mm.

[0058] The energy transmission optical cable also includes:

[0059] The coating layer 3 is coated on the outer surface of the cladding layer 2, the refractive index of the coating layer 3 is 1.7, and the thickness is 0.07mm.

[0060] In the energy transmission optica...

Embodiment 3

[0070] An energy transmission optical cable, comprising:

[0071] A core layer 1, which is made of quartz glass material, the diameter of the core layer 1 is 0.200mm;

[0072] A cladding layer 2, which covers the core layer 1, the cladding layer 2 is made of quartz glass material, and the thickness of the cladding layer 2 is 0.015mm;

[0073] A tight cladding 4 covering the cladding, the tight cladding 4 is made of ethylene-tetrafluoroethylene copolymer material, and the thickness of the tight cladding 4 is 0.4mm;

[0074] The outer sheath 7 covers the tight cladding 4, the outer sheath 7 is made of ethylene-tetrafluoroethylene copolymer material, and the thickness of the outer sheath 7 is 0.3mm.

[0075] The energy transmission optical cable also includes:

[0076] The coating layer 3 is coated on the outer surface of the cladding layer 2, the refractive index of the coating layer 3 is 1.6, and the thickness is 0.06mm.

[0077] In the energy transmission optical cable, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com