Differential speed conveyor security inspection system

A security inspection and differential technology, applied in the field of differential conveying security inspection system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

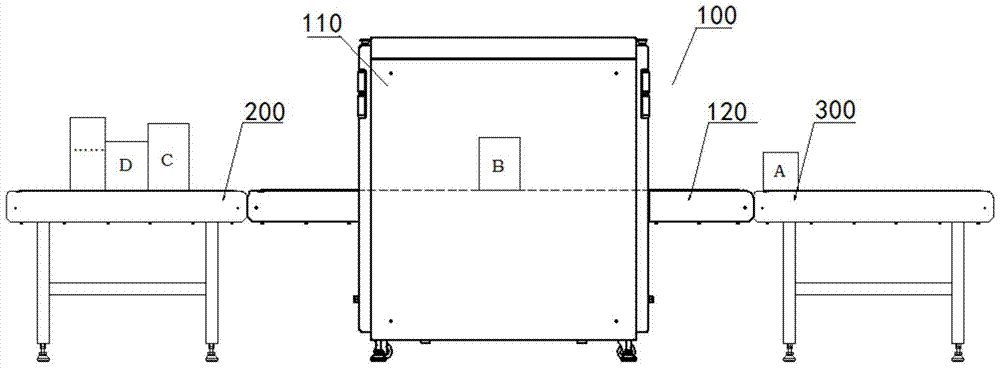

[0048] like figure 1 As shown, this embodiment discloses a security inspection system for differential transmission, which includes a security inspection machine 100 and a power transmission device 200, the security inspection machine 100 includes a detector 110 and a belt conveyor 120, and the detector 110 is arranged on the belt conveyor 120 , to detect the luggage package conveyed by the belt conveyor 120 . The power transmission device 200 is docked at the entrance of the belt conveyor 120, the transmission plane of the power transmission device 200 is on the same level as the transmission plane of the belt conveyor 120, and the transmission direction of the power transmission device 200 and the belt conveyor 120 is the same, and the power The conveying line speed of the conveying device 200 is lower than that of the belt conveyor 120, and the luggage parcels are conveyed to the belt conveyor 120 through the power transmission device 200, and the distance between adjacent ...

Embodiment 2

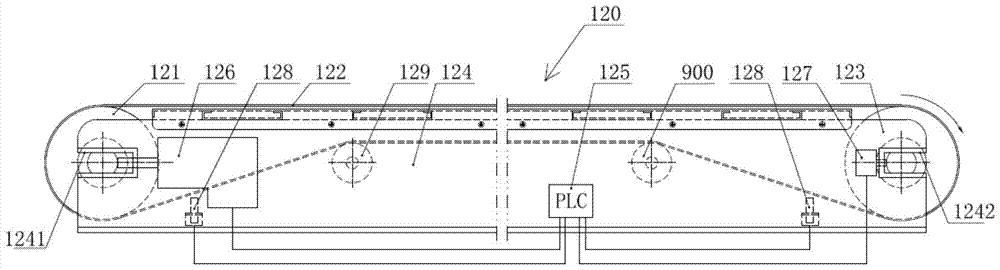

[0054] This embodiment also discloses a security inspection system for differential conveying. This embodiment is further improved on the basis of the first embodiment above. The main difference from the first embodiment is that this embodiment further improves the belt conveyor 120 and the structure of the power transmission device 200. Because the applicant found in the process of using the differential speed conveying security inspection system of Embodiment 1 that if the existing belt conveyor or power transmission device is directly selected for assembly and use, there are some shortcomings: manual frequent debugging is required during production and installation to ensure that the belt The tension and position of the belt conveyor are correct; after delivery to the customer, due to the long-term use of the belt, the belt will loosen and the belt will be displaced from the correct position due to impact, resulting in slippage and reduced service life of the belt conveyor. ...

Embodiment 3

[0069] This embodiment also discloses a security inspection system for differential speed transmission. This embodiment is further improved on the basis of the first embodiment above to solve the problem of applying the existing differential speed transmission security inspection system for belt conveyors or power transmission devices. There are some deficiencies: the existing belt conveyor and power transmission device will cause lateral deviation of the belt due to self-aging and unilateral conveying during the long-term operation process, that is, left and right swings, which can seriously cause belt damage. Therefore, the applicant made a further improvement by adding several automatic belt deviation adjustment devices 400 to the security inspection system. An automatic belt deviation adjustment device 400 is installed below the position of the belt that needs to be adjusted to correct the inclination of the roller 410. It is located under the belt to effectively correct th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com