Device for testing fatigue life of flexible bearing

A technology for flexible bearings and fatigue life, which is applied in the direction of mechanical bearing testing, etc., can solve the problems of no fatigue life, etc., and achieve the effect of improving fatigue life and improving design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

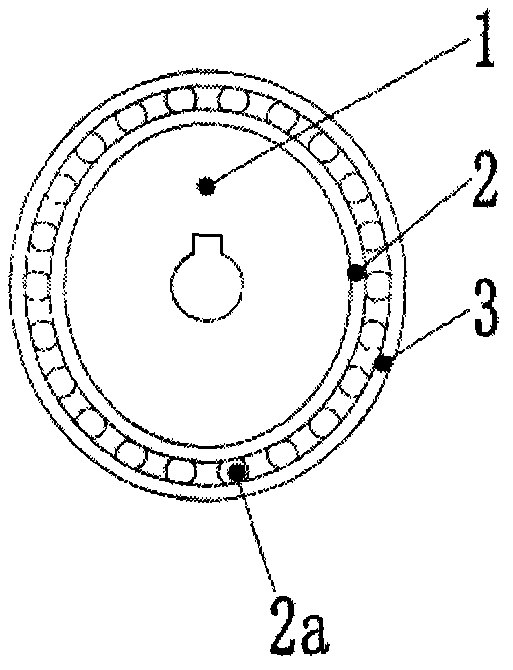

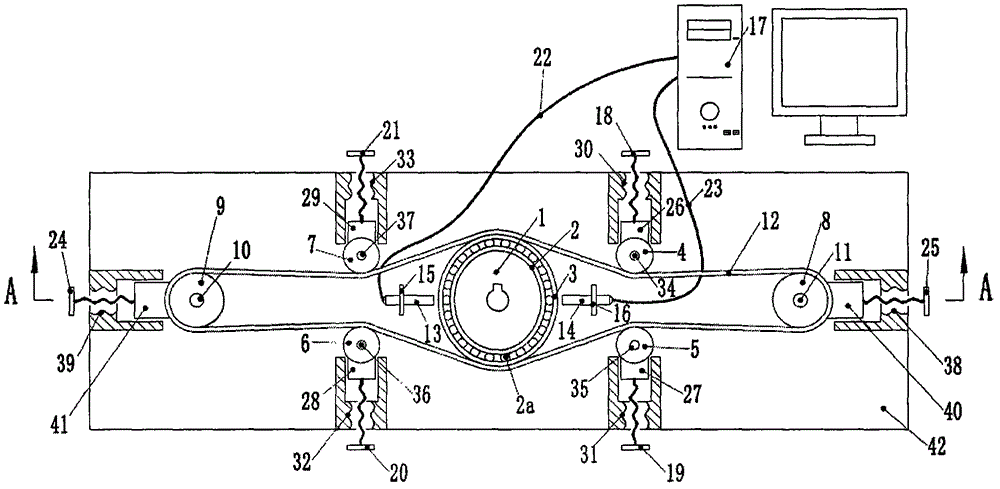

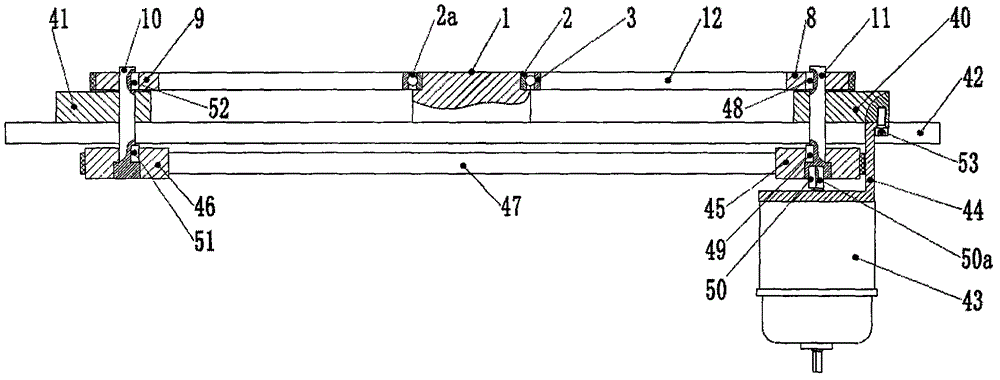

[0018] Such as figure 2 , 3 As shown, the test device is mainly composed of a computer 17, a flaw detection sensor 13, a speed sensor 14, a driver 43, a transmission wheel 8, a transmission wheel 9, a transmission belt 12, a cam 1, a flexible bearing 2a, a tensioning wheel 4, and a tensioning wheel 5 , tensioning pulley 6, tensioning pulley 7, load adjustment device 24, load adjustment device 25, frame 42 and other components. The cam 1 is fixed on the frame 42, the flexible bearing 2a deforms after being inserted into the cam 1, and the flexible bearing inner ring 2 and the flexible bearing outer ring 3 are deformed into an equidistant curve of the profile of the cam 1. The tension wheel adjusting device 18 adjusts the position of the slider 26 through the screw pair 30 , and the tension wheel 4 is connected with the slider 26 through the connecting shaft 34 . The tension wheel adjusting device 19 adjusts the position of the slider 27 through the screw pair 31 , and the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com