A fuel injection control valve and a high-pressure common rail fuel injection system using the fuel injection control valve

A technology of control valves and electromagnetic control valves, which is applied in the direction of fuel injection devices, charging systems, engine components, etc., can solve the difficulty of processing key parts of electronically controlled fuel injectors, restrict the promotion and application of common rail systems, and product qualification Low efficiency and other problems, to achieve the effect of improving fuel injection response speed, increasing service life and improving combustion characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

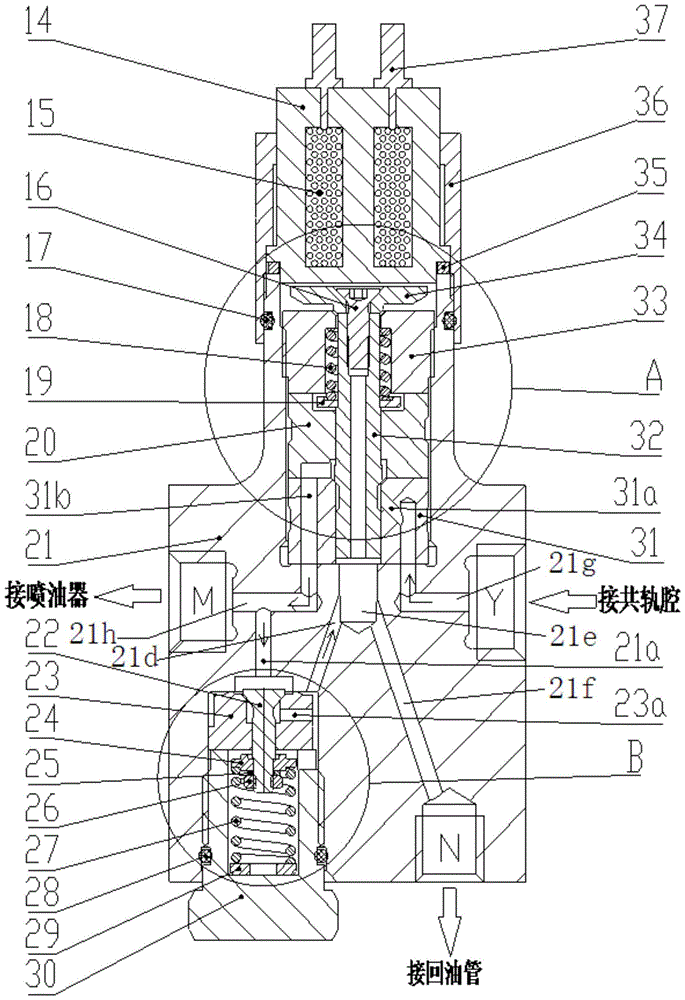

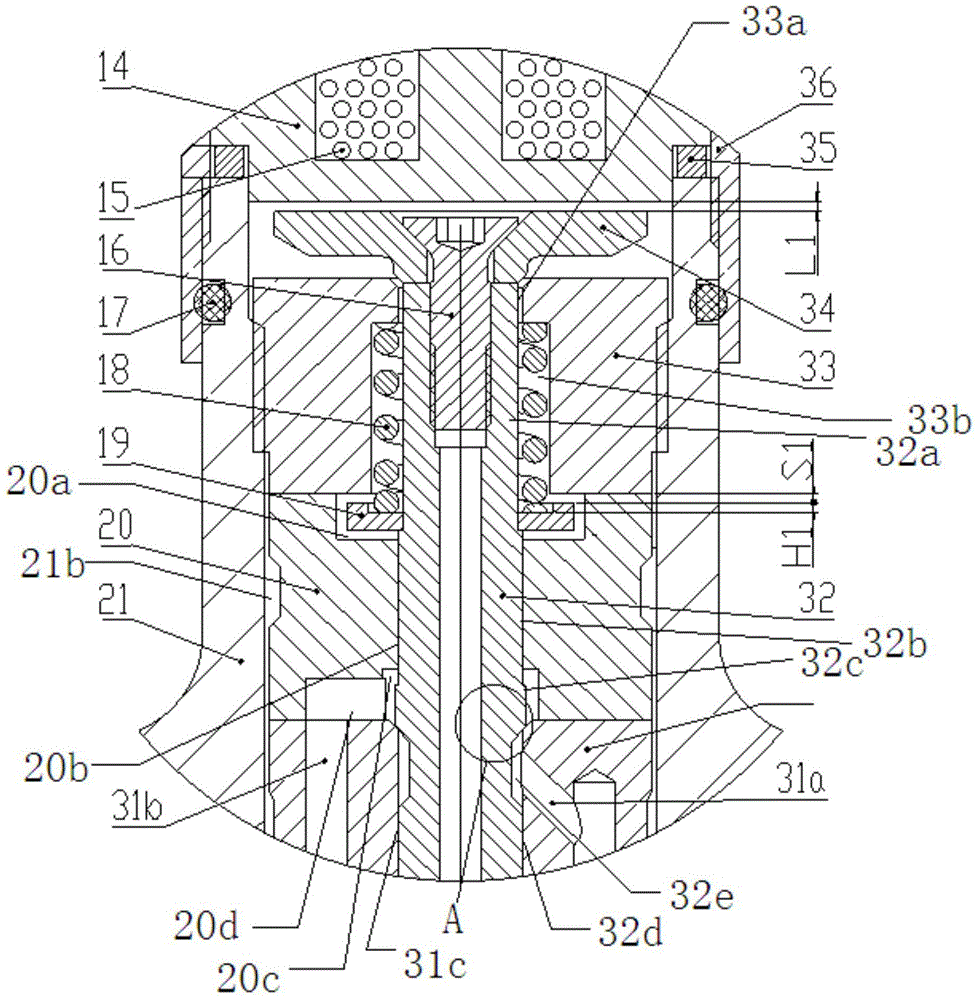

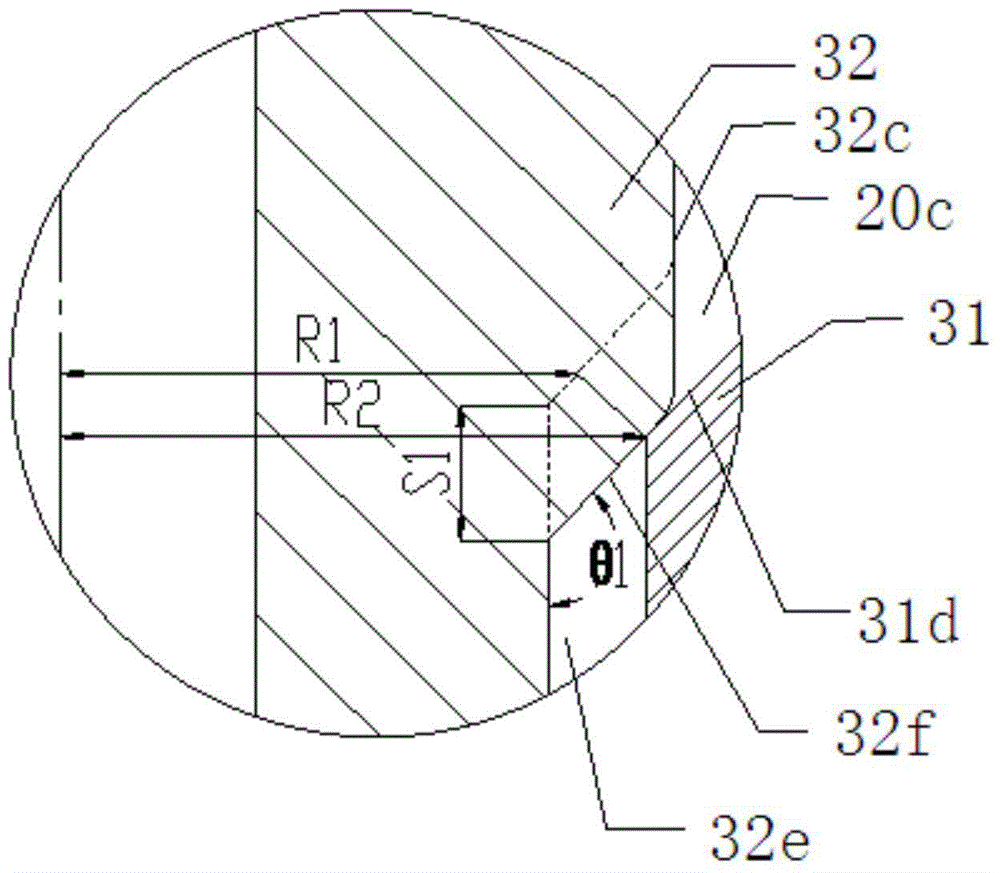

[0046] see Figure 1 to Figure 5 , the fuel injection control valve shown in the figure includes a valve body 21, an electromagnetic control valve component and a pressure relief valve component.

[0047] The upper part of the valve body 21 is provided with an electromagnetic control valve component installation cavity 21b, the two sides of the middle part are respectively provided with a common rail cavity interface Y and an injector interface M, and the lower part is equipped with a pressure relief valve component installation cavity 21c and an oil return pipe interface N; The valve body 21 is equipped with a pressure relief valve oil inlet passage 21d, an oil relief valve return oil passage 21a, an oil return chamber 21e, a total oil return p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com