Novel common-rail fuel injector

A technology of common rail injectors and injectors, which is applied in the direction of machines/engines, fuel injection devices, engine components, etc., can solve the problems of low product qualification rate, restrictions on the promotion and application of common rail systems, and complex tolerance detection and manufacturing Cost and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

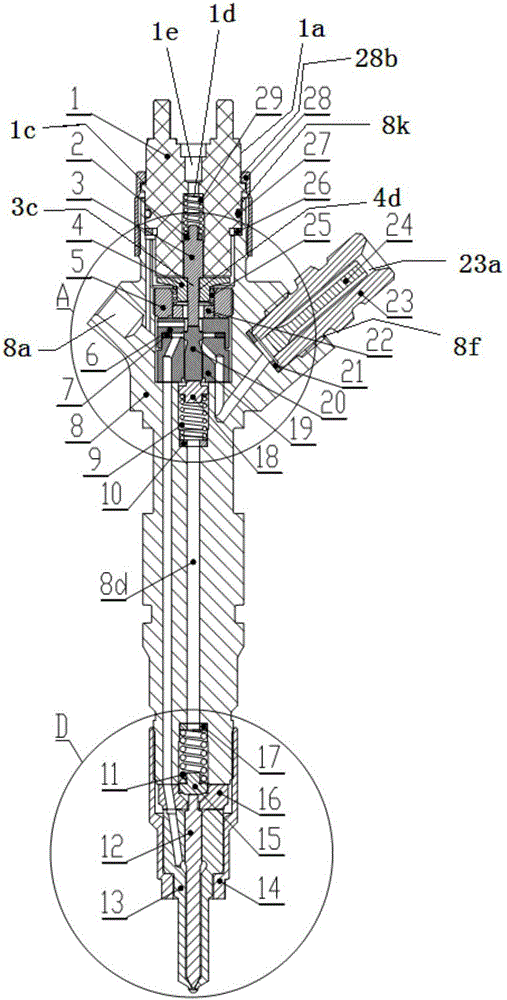

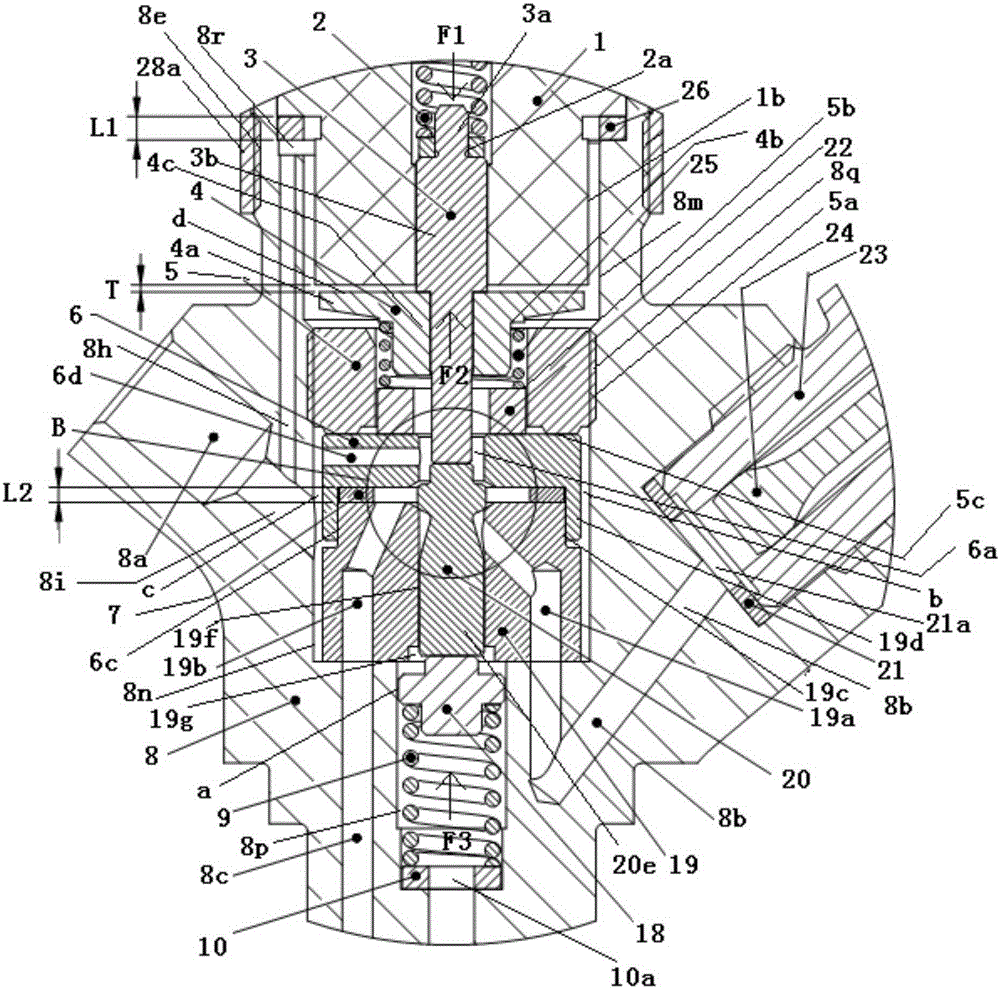

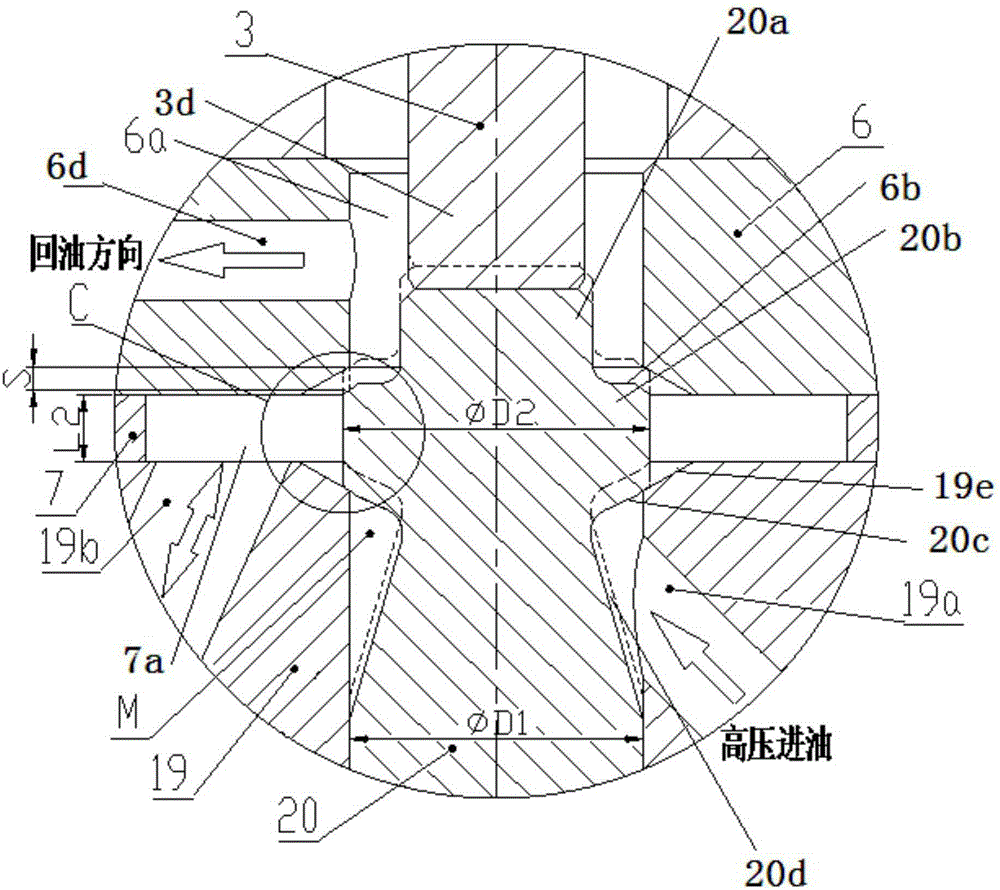

[0055] see Figure 1 to Figure 7 , a new type of common rail injector shown in the figure is assembled from injector parts, solenoid valve parts and fuel injector parts. The specific structure is as follows:

[0056] The fuel injector body components include fuel injector body 8, sealing gasket 21, fuel inlet pipe joint 23, and slot filter element 24. The fuel injector body 8 is provided with an upper external thread 8e, an oil return pipe joint installation hole 8a, and an oil inlet pipe joint. The installation hole 8f and the lower external thread 8g, the upper and lower external threads 8e, 8g are respectively arranged on the upper and lower ends of the outer edge of the injector body 8, and the oil return pipe joint installation hole 8a and the oil inlet pipe joint installation hole 8f are arranged on the injector Upper middle position of the body.

[0057] In the injector body, there are installation holes for solenoid valve components, oil inlet passage 8b, first oil re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com