Reinforcing method for improving stability of gob-side entry driving small coal pillar

A small coal pillar and stability technology, which is used in earth-moving drilling, wellbore lining, tunnel lining, etc., can solve the problems of large loose area of small coal pillars, coal pillars, and reduced coal pillar stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

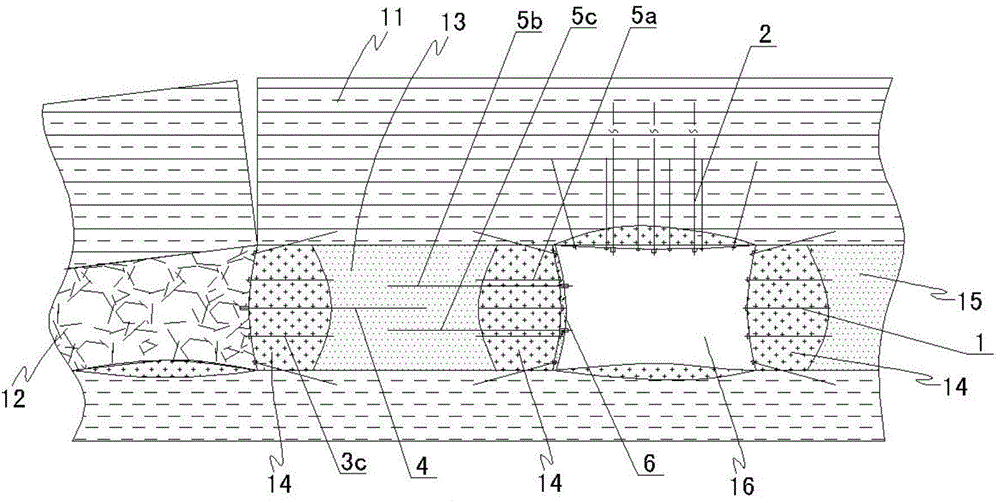

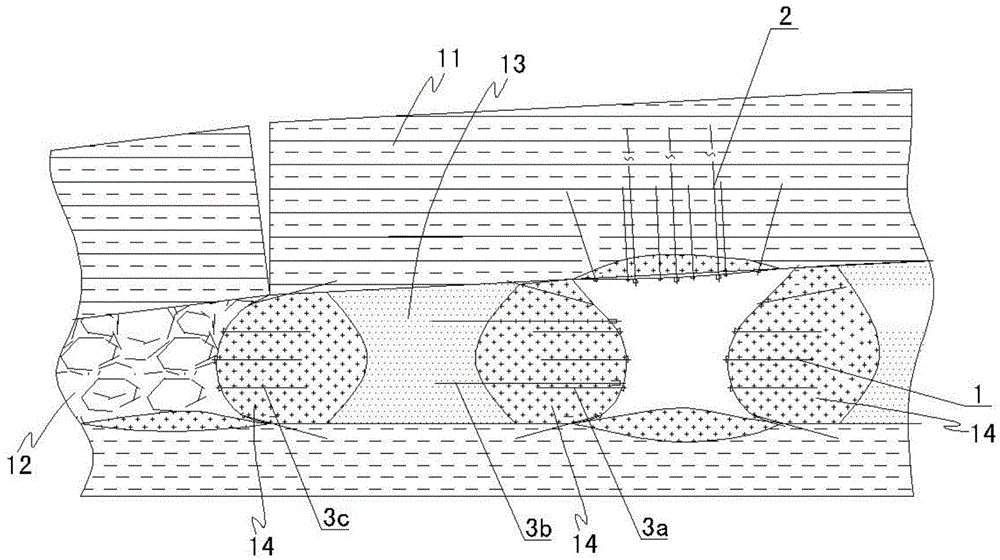

[0022] see figure 1 , the reinforcement method to improve the stability of small coal pillars along the goaf roadway in this embodiment is:

[0023] Before mining in the working face of the upper section, the roadway 12 in the upper section is adjacent to the sidewall of the lower section, and is located on the side of the upper section of the small coal pillar. The length L1 of the pre-reinforced anchor cable 4 of the roadway side satisfies: L1≮B / 2+1.0m, where B is the design width of the small coal pillar, and the unit is m.

[0024] In the process of gob-side excavation in the lower section, multiple small coal pillar side anchor rods 5a and multiple small coal pillar side reinforcement anchor cables are installed at the small coal pillar side sides, wherein the small coal pillar side reinforcement anchor cables include small coal pillar side reinforcement anchor cables. Hollow grouting reinforcement anchor cable 5b and conventional reinforcement anchor cable 5c at the si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com