Plug type sand control method for slim hole sidetracked well

A drilling plug type and sand control technology, which is applied in wellbore/well components, earthwork drilling and production, and production fluid, etc. It can solve problems such as high construction pressure, casing changes in the lower wellbore, and difficult handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

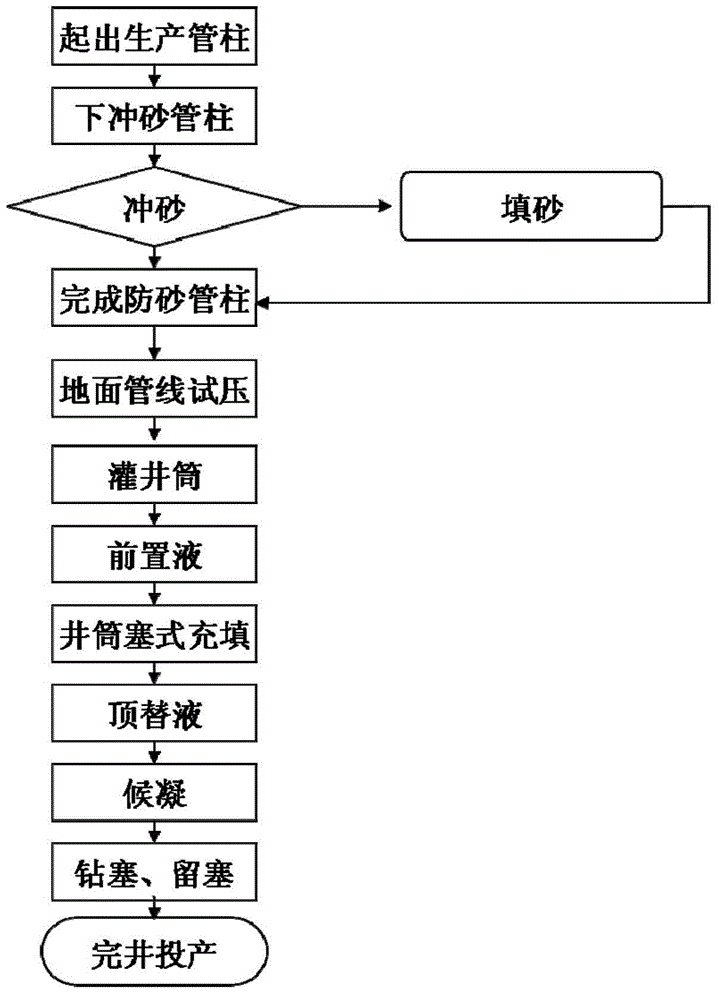

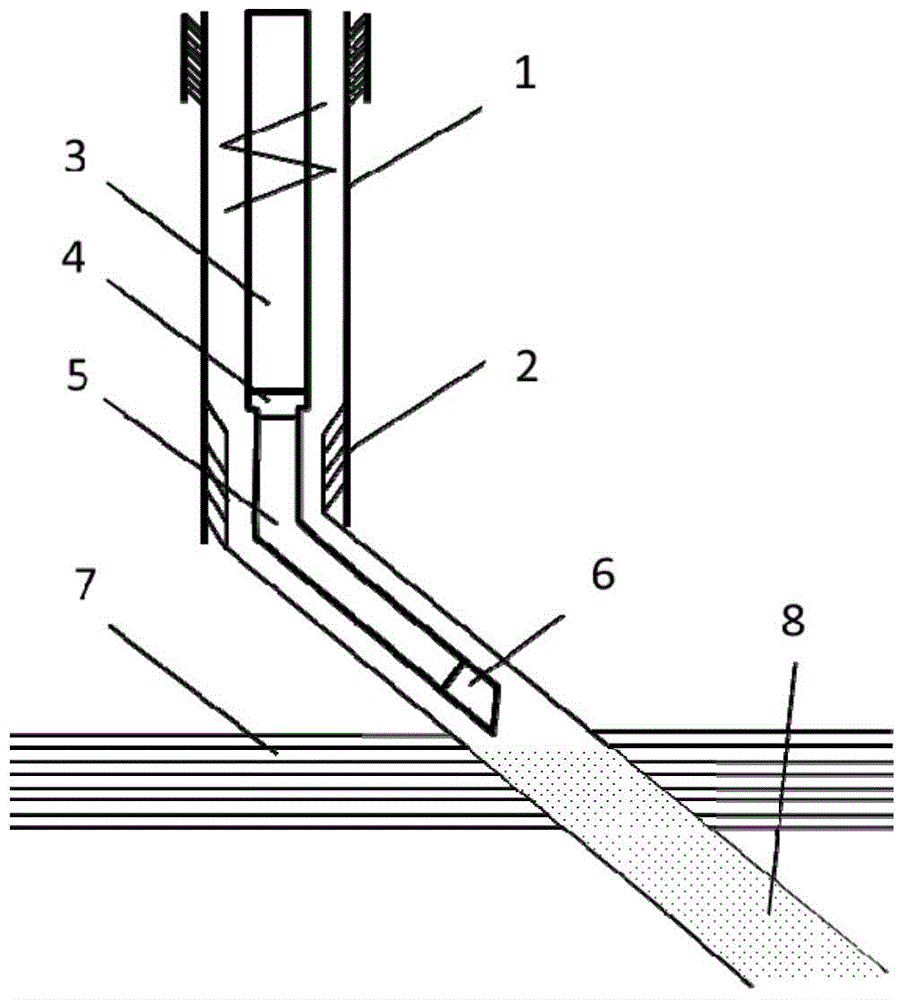

[0029] Such as figure 1 As shown, the Gang 284-1k well is a sidetrack 1 in the Gangdong Oilfield of Dagang Oilfield. The hanger 2 is 792.28-794.48m, the window is 863-866mm, the casing outer diameter of the straight section is φ139.7mm, and the inner diameter is φ124. .1mm, the casing outer diameter of the sidetracking slim hole section is φ95.25mm, the inner diameter is φ82.25mm, the production zone is NmⅢ4, and the sand control target zone 7 is 1590.8-1595m.

[0030] S1. Start the production string in the oil well, including tubing, sucker rod and oil pump.

[0031] S2. Lower sand flushing pipe string, Φ73mm tubing 3+900m Φ60.3mm tubing 5+Φ60.3mm pen point 6 threaded connection in sequence, sand detecting surface, sand surface position 1559.8m.

[0032] S3. The 400 type pump truck is used to pump clean water and sand flushing fluid into the flushing pipe string to flush the sand to 1626m, 31m away from the bottom of the sand control target layer, and 4 hours after the well is shut ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com