A long screw pile machine

A technology of long auger pile driver and auger bit, which is applied to the driving device of rotary combined drilling, drilling equipment, earthwork drilling and production, etc., and can solve the problems of delay in construction period, waste of drill bits, and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings. (The description below is as clear as possible, with data plus some data)

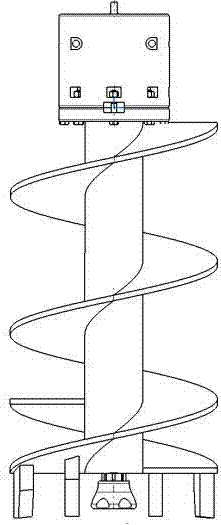

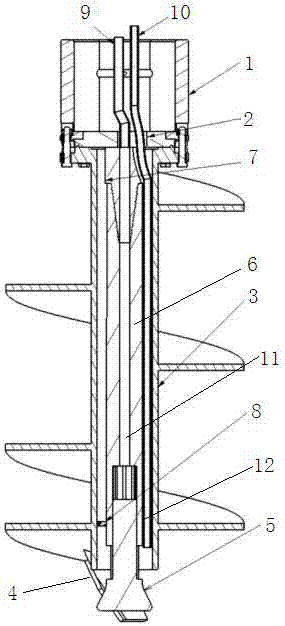

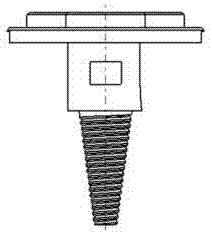

[0014] As shown in the figure, a long screw pile machine consists of two parts: a pile frame and a drilling system. System and electrical system, the input system includes the power head and the drilling tool, the screw drill rod (output shaft) of the power head is connected with the screw drill bit 1, the flange 2 and the auger bit 3, and the lower end surface of the auger bit 3 is provided with Drilling tool 4, the structure of above-mentioned each component and the interconnection relation between them are identical with prior art, this does not go into details, the feature of the present invention is that auger bit 3 is provided with central through hole, and in the central through hole of auger bit 3 There is a down-the-hole hammer 5 protruding from the drilling tool. The upper end of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com