A kind of high alkali-resistant textile scouring agent and preparation method thereof

A scouring agent and high alkali-resistant technology, which is applied in textiles, papermaking, fiber treatment, etc., can solve the problems of biological toxicity of additives, few varieties of scouring agents, unstable quality, etc., and achieve good stability, good cleaning effect, good hair effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

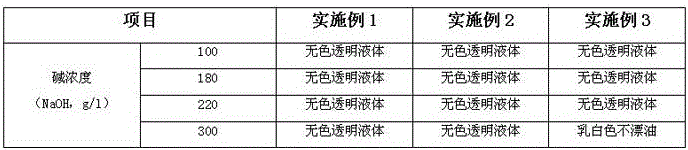

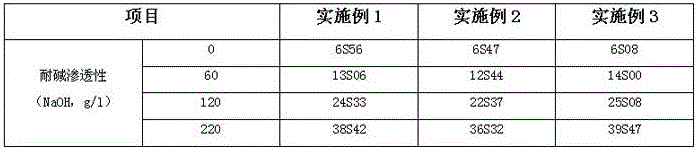

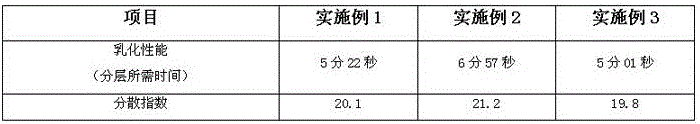

Examples

preparation example Construction

[0029] A preparation method of a high alkali-resistant textile scouring agent, the preparation steps are as follows:

[0030] Step 1: Preparation of surfactant stock solution: add 30-40% of the total weight of water required for the formula into the chemical tank and heat to 60-75°C, add isomeric alcohol polyoxyethylene ether, alkyl Glycoside and sodium ethoxylated alkylsulfate, the addition amount is based on the total content of the refined refining agent, after dissolving, stir for 0.5-1h to make it uniform, to obtain a mixed solution A, and set aside;

[0031] Step 2: Preparation of antifoaming agent stock solution: take another 30-40% of the water in the formula and add it to another chemical tank, and heat it to 50-60°C, and then add the antifoaming agent while stirring according to the weight ratio. Stir continuously until the solution is uniform and transparent to obtain a mixed solution B, which is set aside;

[0032] Step 3: fully mix the mixed solution A prepared i...

Embodiment 1

[0036] A high alkali-resistant textile scouring agent is proportioned according to the following percentages by weight:

[0037] Isomerized tridecyl alcohol polyoxyethylene ether (ethoxyl addition number is 9) 22%, alkyl glycoside 18%, ethoxylated alkyl sodium sulfate 10%, ethylene glycol monobutyl ether 5%, propylene glycol 2 %, EDTA0.5%, methyl silicone oil 0.5%, deionized water 42%.

[0038] Its preparation process is:

[0039] Preparation of liquid A: Add 40% of the total weight of deionized water into the chemical tank and heat it to 70°C, add isotridecyl alcohol polyoxyethylene ether, alkyl glycoside, and ethoxylated alkyl group while stirring according to the above raw material ratio Sodium sulfate, the addition amount is based on the total content of the refined refining agent, after dissolving, stir for 0.5h to make it uniform.

[0040] Preparation of liquid B: add 40% of the total weight of deionized water into the chemical tank and heat to 60°C, add antifoaming ag...

Embodiment 2

[0043] A high alkali-resistant textile scouring agent is formulated according to the following percentages by weight: isomeric tridecyl alcohol polyoxyethylene ether (ethoxylate addition number is 9) 25%, alkyl glycoside 25%, ethoxylated Sodium alkyl sulfate 15%, ethylene glycol monobutyl ether 5%, absolute ethanol 4%, ethylenediaminetetraacetic acid EDTA 0.2%, polydimethylsilicone oil 1.0%, deionized water 24.8%.

[0044] Its preparation process is:

[0045] Preparation of liquid A: Add 30% of the total weight of deionized water into the chemical tank and heat it to 68°C, add isotridecyl alcohol polyoxyethylene ether, alkyl glycoside, and ethoxylated alkyl group while stirring according to the above raw material ratio Sodium sulfate, the amount added is based on the total content of the refined refining agent, after dissolving, stir for 1 hour to make it uniform.

[0046] Preparation of liquid B: add 30% of the total weight of deionized water into the chemical tank and heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com