Padding, wet steaming and dyeing method of reactive dye

A technology of reactive dyes and dyeing methods, applied in dyeing methods, textile material processing, removal of liquid/gas/vapor, etc., can solve the problems of adverse effects on dyeing and color fixing, hydrolysis of reactive dyes, consumption of large heat energy, etc. To achieve the effect of shortening wet steaming and fixing time, reducing hydrolysis and accelerating heating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

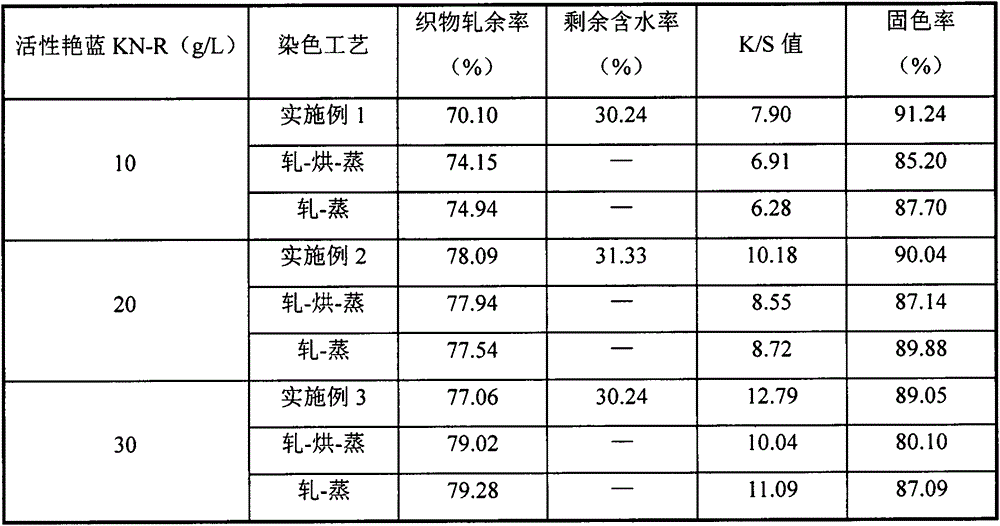

[0022] The dyeing process of Examples 1-3: padding dye solution (two dipping and two padding)→vacuum dehumidification→wet steaming to fix the color.

[0023] The dye liquor was prepared according to the dosage of the dyestuff mentioned in Table 1, and the corresponding vacuum dehumidification and steam fixation were carried out on the cotton fabric dipped in the dye liquor.

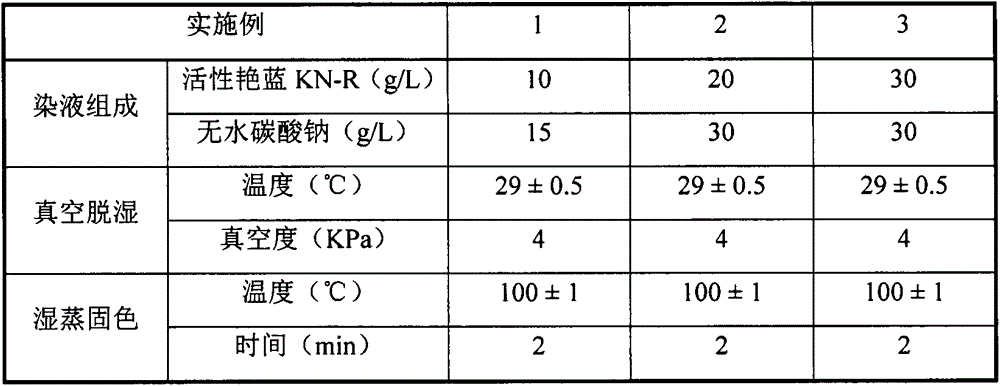

[0024] The dye liquor composition and dyeing process condition of table 1 embodiment 1~3

[0025]

[0026] With conventional pad-dry-steaming process and pad-steaming process to carry out the experiment of cotton fabric reactive dye dyeing as control group, dye solution prescription is identical with embodiment 1,2,3 respectively, and dyeing process is:

[0027] Pad-dry-steam process: Pad dyeing solution (two dipping and two pads)→pre-drying (80°C, 3min)→atmospheric saturated steam steaming and fixing (100±1°C, 2min)

[0028] Pad-steam process: Pad dyeing solution (two dips and two pads) → atmospheric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com